Machine learning enhances industrial engineering by enabling systems to learn from data and adapt to new conditions without explicit programming, unlike traditional automation that relies on preset instructions. This adaptability improves predictive maintenance, quality control, and process optimization, leading to increased efficiency and reduced downtime. Machine learning models can process complex data patterns beyond the capability of conventional fixed-rule systems, driving smarter decision-making in manufacturing environments.

Table of Comparison

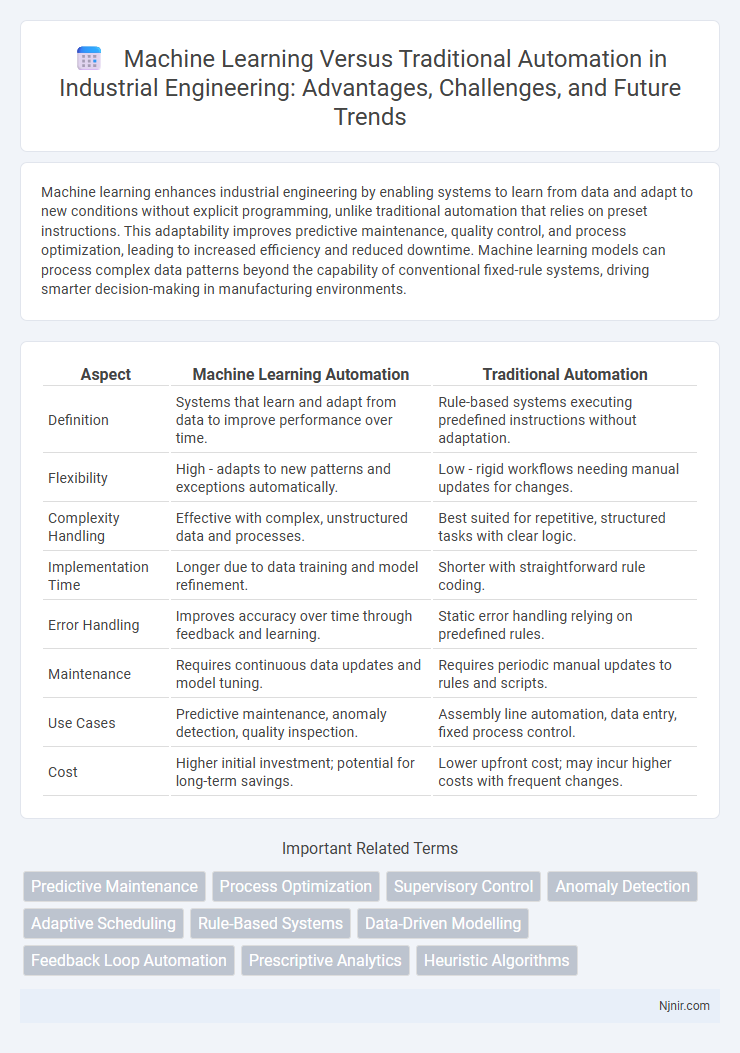

| Aspect | Machine Learning Automation | Traditional Automation |

|---|---|---|

| Definition | Systems that learn and adapt from data to improve performance over time. | Rule-based systems executing predefined instructions without adaptation. |

| Flexibility | High - adapts to new patterns and exceptions automatically. | Low - rigid workflows needing manual updates for changes. |

| Complexity Handling | Effective with complex, unstructured data and processes. | Best suited for repetitive, structured tasks with clear logic. |

| Implementation Time | Longer due to data training and model refinement. | Shorter with straightforward rule coding. |

| Error Handling | Improves accuracy over time through feedback and learning. | Static error handling relying on predefined rules. |

| Maintenance | Requires continuous data updates and model tuning. | Requires periodic manual updates to rules and scripts. |

| Use Cases | Predictive maintenance, anomaly detection, quality inspection. | Assembly line automation, data entry, fixed process control. |

| Cost | Higher initial investment; potential for long-term savings. | Lower upfront cost; may incur higher costs with frequent changes. |

Overview of Machine Learning and Traditional Automation

Machine learning involves algorithms that enable systems to learn from data patterns and improve performance without explicit programming, contrasting with traditional automation which relies on predefined rules and scripts for task execution. Machine learning adapts dynamically to new inputs, enhancing decision-making accuracy and enabling predictive analytics, while traditional automation performs repetitive, rule-based processes with consistent, but limited, flexibility. The growing volume of data and computational power has accelerated machine learning adoption in applications like image recognition, natural language processing, and autonomous systems compared to static traditional automation solutions.

Key Differences in Industrial Engineering Applications

Machine learning in industrial engineering enables adaptive decision-making by analyzing complex data patterns, whereas traditional automation relies on fixed, rule-based processes for repetitive tasks. Machine learning systems improve efficiency through predictive maintenance and quality control by continuously learning from sensor data, unlike traditional automation which operates on pre-defined scripts without self-improvement. The integration of machine learning supports dynamic optimization and anomaly detection in manufacturing, surpassing the static operational limits of conventional automation technologies.

Data Requirements and Input Handling

Machine learning systems require vast amounts of diverse, high-quality data to identify patterns and improve performance over time, whereas traditional automation relies on pre-defined, rule-based inputs with limited flexibility. Machine learning algorithms can handle unstructured and complex data types such as images, text, and sensor data, enabling adaptive decision-making. In contrast, traditional automation depends on structured, deterministic inputs and fails to adjust to new or unexpected data without manual reprogramming.

Flexibility and Adaptability in Manufacturing Processes

Machine learning enhances flexibility in manufacturing by enabling systems to learn from data patterns and adjust operations in real time, unlike traditional automation which relies on pre-programmed, rigid instructions. This adaptability allows machine learning-driven processes to handle variations in production without manual reconfiguration, significantly reducing downtime and increasing efficiency. As a result, manufacturers achieve optimized performance and quicker response to changing market demands.

Implementation Complexity and Cost Comparison

Machine learning implementation involves advanced algorithms and significant data preprocessing, resulting in higher initial development complexity compared to traditional automation's rule-based systems with straightforward programming. The cost of machine learning is elevated due to the need for specialized talent, extensive data infrastructure, and iterative model training, whereas traditional automation generally incurs lower upfront expenses with predictable maintenance costs. Over time, machine learning offers scalable adaptability and potentially greater efficiency savings, while traditional automation remains cost-effective for repetitive, well-defined tasks but lacks flexibility for evolving processes.

Scalability for Industrial Operations

Machine learning enables industrial operations to scale by adapting to complex, dynamic environments through continuous data-driven learning, unlike traditional automation which relies on static, rule-based processes that limit flexibility. Industrial-scale applications with machine learning can handle vast amounts of data and evolving patterns, optimizing production efficiency and reducing downtime. Traditional automation systems often struggle with scalability due to rigid programming and lack of real-time adaptability, constraining performance in large-scale, variable industrial settings.

Error Detection and Maintenance Capabilities

Machine learning enhances error detection by continuously analyzing data patterns and adapting to new anomalies, unlike traditional automation which relies on predefined rules and fixed thresholds. This adaptive capability allows machine learning systems to identify complex and evolving errors in real-time, improving predictive maintenance and reducing downtime. Traditional automation requires manual updates for maintenance protocols, whereas machine learning-driven solutions proactively optimize maintenance schedules through data-driven insights.

Real-Time Decision Making and Optimization

Machine learning enables real-time decision making by continuously analyzing data patterns and adapting algorithms without explicit programming, enhancing optimization in dynamic environments. Traditional automation relies on predefined rules that lack flexibility, limiting its ability to respond promptly to changing conditions. Real-time optimization through machine learning improves accuracy and efficiency across applications like predictive maintenance, supply chain management, and personalized recommendations.

Integration with Existing Industrial Systems

Machine Learning integrates with existing industrial systems by enabling adaptive decision-making through real-time data analysis, enhancing predictive maintenance and process optimization beyond rigid rule-based traditional automation. Traditional automation relies on predefined control logic and repetitive task execution, which limits flexibility when adapting to complex, dynamic industrial environments. Machine Learning models continuously learn from sensor inputs and operational data, facilitating seamless interaction with SCADA, PLCs, and MES systems for smarter, more responsive industrial workflows.

Future Trends in Smart Manufacturing Automation

Machine learning enhances smart manufacturing automation by enabling predictive maintenance and adaptive process optimization, surpassing traditional rule-based automation systems. Future trends include integrating AI-driven analytics with IoT data to create self-learning production lines that improve efficiency and reduce downtime. The shift towards hyper-automation leverages machine learning models to dynamically adjust operations in real time, driving innovation in Industry 4.0 environments.

Predictive Maintenance

Machine learning enhances predictive maintenance by enabling real-time data analysis and adaptive failure prediction, outperforming traditional automation's rule-based, static maintenance schedules.

Process Optimization

Machine learning enhances process optimization by enabling adaptive decision-making and predicting outcomes, whereas traditional automation relies on predefined rules and static workflows.

Supervisory Control

Supervisory control in machine learning enables adaptive decision-making through real-time data analysis, surpassing traditional automation's fixed-rule execution in complex dynamic environments.

Anomaly Detection

Machine learning enables more accurate and adaptive anomaly detection by leveraging complex data patterns and continuous learning, surpassing traditional automation's reliance on static, rule-based systems.

Adaptive Scheduling

Adaptive scheduling in machine learning dynamically optimizes workflows using data-driven predictions, outperforming traditional automation's fixed rule-based scheduling by enhancing efficiency and responsiveness.

Rule-Based Systems

Machine learning enhances automation by adapting to data patterns beyond static, rule-based systems that rely on predefined, rigid logic for decision-making.

Data-Driven Modelling

Machine learning leverages data-driven modeling to adapt and improve performance autonomously, whereas traditional automation relies on predefined, rule-based processes with limited flexibility.

Feedback Loop Automation

Feedback loop automation in machine learning continuously refines models through real-time data inputs, outperforming traditional automation's static, rule-based processes.

Prescriptive Analytics

Prescriptive analytics in machine learning leverages advanced algorithms and real-time data to recommend optimal actions, whereas traditional automation relies on predefined rules and static workflows for decision-making.

Heuristic Algorithms

Heuristic algorithms in machine learning adapt and improve decision-making from data patterns, while traditional automation relies on fixed, rule-based heuristics without learning capabilities.

Machine Learning vs Traditional Automation Infographic

njnir.com

njnir.com