Circular manufacturing emphasizes resource efficiency by designing products for reuse, recycling, and minimal waste generation, contrasting with linear manufacturing's traditional "take-make-dispose" model. This approach reduces environmental impact and conserves raw materials by keeping products and materials in use for as long as possible. Implementing circular principles boosts sustainability and economic resilience within industrial engineering processes.

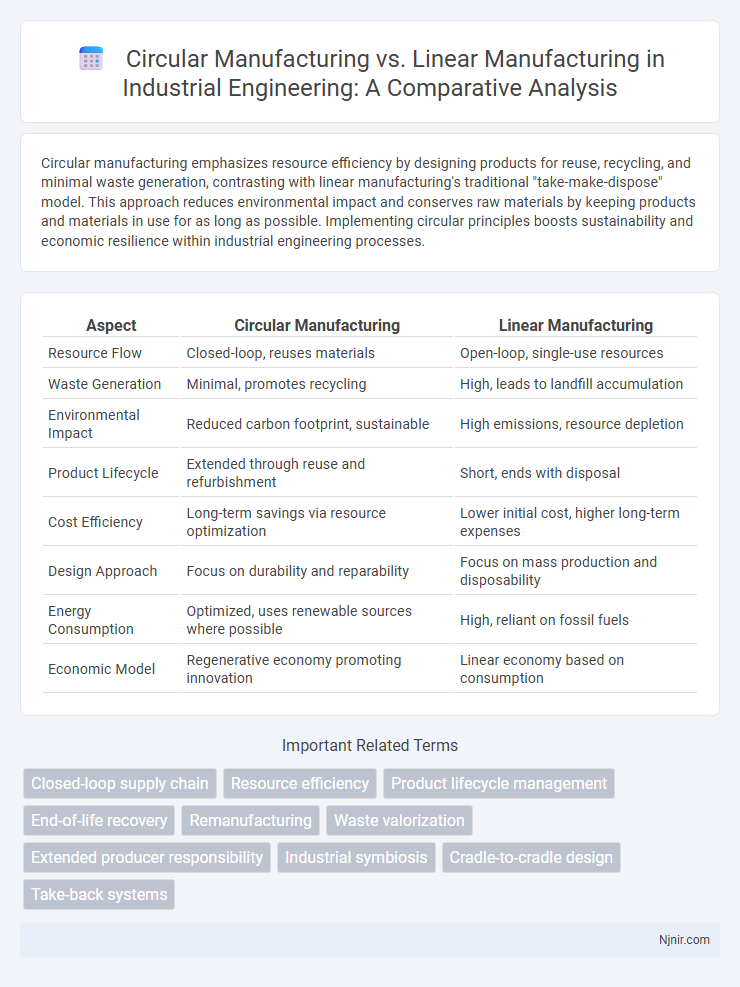

Table of Comparison

| Aspect | Circular Manufacturing | Linear Manufacturing |

|---|---|---|

| Resource Flow | Closed-loop, reuses materials | Open-loop, single-use resources |

| Waste Generation | Minimal, promotes recycling | High, leads to landfill accumulation |

| Environmental Impact | Reduced carbon footprint, sustainable | High emissions, resource depletion |

| Product Lifecycle | Extended through reuse and refurbishment | Short, ends with disposal |

| Cost Efficiency | Long-term savings via resource optimization | Lower initial cost, higher long-term expenses |

| Design Approach | Focus on durability and reparability | Focus on mass production and disposability |

| Energy Consumption | Optimized, uses renewable sources where possible | High, reliant on fossil fuels |

| Economic Model | Regenerative economy promoting innovation | Linear economy based on consumption |

Defining Circular and Linear Manufacturing

Circular manufacturing emphasizes resource efficiency by designing products for reuse, remanufacturing, and recycling, minimizing waste and environmental impact. Linear manufacturing follows a traditional "take-make-dispose" model, extracting raw materials, producing goods, and generating waste without reclaiming resources. Circular manufacturing supports sustainability through closed-loop systems, while linear manufacturing often results in resource depletion and increased landfill accumulation.

Key Principles of Circular Manufacturing

Circular manufacturing emphasizes resource efficiency through principles such as designing for durability, reuse, and recyclability to minimize waste and environmental impact. It prioritizes closed-loop systems where materials and products continuously flow back into production cycles rather than being discarded. This approach contrasts with linear manufacturing's take-make-dispose model, focusing instead on regenerative processes to sustain long-term resource availability.

Traditional Linear Manufacturing Model Overview

The traditional linear manufacturing model follows a straightforward path: raw materials are extracted, transformed into products, and disposed of as waste after use, resulting in significant resource depletion and environmental impact. This take-make-dispose approach lacks mechanisms for recycling or reusing materials, contributing to increasing landfill volumes and pollution. Efficiency losses in resource utilization and energy consumption further highlight the model's unsustainability compared to emerging circular manufacturing paradigms.

Resource Efficiency: Circular vs Linear Approaches

Circular manufacturing maximizes resource efficiency by continuously recycling materials and designing products for reuse, reducing raw material extraction and waste generation. Linear manufacturing relies on a take-make-dispose model, resulting in significant resource depletion and increased environmental impact. The circular approach promotes sustainable resource management through closed-loop systems, enhancing long-term economic and ecological benefits.

Waste Management Strategies in Each Model

Circular manufacturing employs waste management strategies centered on resource recovery, recycling, and product life extension, minimizing landfill use and promoting sustainable material loops. Linear manufacturing generates significant waste by following a take-make-dispose model, often leading to higher landfill rates and resource depletion due to single-use products. Advanced waste segregation, remanufacturing, and eco-design principles are integral to circular models, contrasting with the linear approach's reliance on end-of-life disposal.

Environmental Impacts: Circular vs Linear Manufacturing

Circular manufacturing significantly reduces environmental impacts by minimizing waste and maximizing resource efficiency through reuse, recycling, and remanufacturing processes. Linear manufacturing generates substantial environmental burdens, including increased raw material extraction, energy consumption, and landfill waste, contributing to pollution and resource depletion. The circular approach supports carbon footprint reduction and biodiversity preservation by fostering sustainable material cycles and reducing the need for virgin resource extraction.

Economic Implications and Cost Considerations

Circular manufacturing reduces material costs by emphasizing reuse, remanufacturing, and recycling, lowering the need for raw materials and minimizing waste disposal expenses. Linear manufacturing incurs higher operational costs due to continuous procurement of virgin materials and increased waste management, leading to less efficient resource utilization. Economic implications favor circular models as they enhance long-term profitability through resource efficiency, reduced environmental impact fees, and resilience against supply chain disruptions.

Innovation and Technological Integration

Circular manufacturing drives innovation by emphasizing resource efficiency, waste reduction, and product lifecycle extension through advanced technologies like IoT, AI, and additive manufacturing. Linear manufacturing relies on a one-way flow of materials from production to disposal, often lacking integration of digital tools that enhance sustainability and operational efficiency. The integration of real-time data analytics and smart automation in circular models enables predictive maintenance and closed-loop supply chains, fostering continuous technological advancement.

Challenges and Barriers to Implementation

Circular manufacturing faces significant challenges including high initial investment costs, complex supply chain redesigns, and limitations in material recovery technologies compared to linear manufacturing. Regulatory uncertainty and lack of standardized metrics create barriers for companies transitioning from traditional linear models focused on take-make-dispose processes. Consumer behavior and market demand for circular products remain inconsistent, delaying widespread adoption despite environmental and economic benefits.

Future Trends in Industrial Manufacturing Models

Future trends in industrial manufacturing emphasize a shift from linear models, which follow a take-make-dispose approach, to circular manufacturing that prioritizes resource efficiency, waste reduction, and product lifecycle extension. Advanced technologies such as IoT, AI, and digital twins enable real-time tracking and optimization of material flows, supporting the circular economy framework. Companies adopting circular manufacturing models report increased sustainability, cost savings, and resilience against supply chain disruptions, driving widespread industry transformation.

Closed-loop supply chain

Closed-loop supply chain in circular manufacturing minimizes waste by recycling materials back into production, contrasting with linear manufacturing's traditional cradle-to-grave model that leads to resource depletion.

Resource efficiency

Circular manufacturing maximizes resource efficiency by continuously recycling materials and minimizing waste, unlike linear manufacturing which relies on a one-way flow of raw materials leading to higher resource depletion.

Product lifecycle management

Circular manufacturing enhances product lifecycle management by prioritizing resource efficiency, reuse, and recycling, whereas linear manufacturing follows a one-way, consumption-driven lifecycle from production to disposal.

End-of-life recovery

Circular manufacturing prioritizes end-of-life recovery by reclaiming materials for reuse and reducing waste, whereas linear manufacturing typically discards products after use, leading to resource depletion.

Remanufacturing

Remanufacturing in circular manufacturing significantly reduces raw material consumption and waste generation compared to linear manufacturing by restoring used products to like-new condition through systematic disassembly, cleaning, and reassembly processes.

Waste valorization

Circular manufacturing maximizes waste valorization by transforming waste materials into valuable resources, unlike linear manufacturing which often leads to waste accumulation and resource depletion.

Extended producer responsibility

Extended producer responsibility (EPR) in circular manufacturing mandates producers to manage product lifecycle impacts, significantly reducing waste compared to linear manufacturing's take-make-dispose model.

Industrial symbiosis

Industrial symbiosis enhances circular manufacturing by facilitating resource sharing and waste reduction among industries, contrasting with linear manufacturing's one-way resource consumption and disposal model.

Cradle-to-cradle design

Cradle-to-cradle design in circular manufacturing prioritizes continuous resource reuse and waste elimination, contrasting linear manufacturing's one-way consumption and disposal model.

Take-back systems

Circular manufacturing employs take-back systems to recover and recycle products, minimizing waste, while linear manufacturing typically lacks such systems, leading to higher resource consumption and disposal.

Circular manufacturing vs Linear manufacturing Infographic

njnir.com

njnir.com