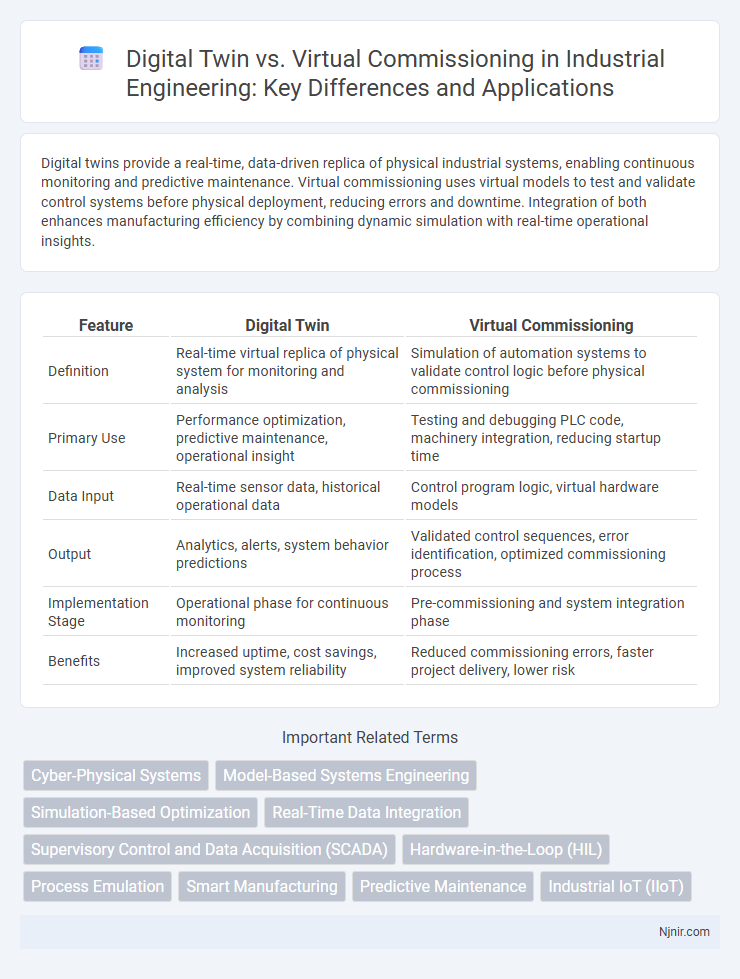

Digital twins provide a real-time, data-driven replica of physical industrial systems, enabling continuous monitoring and predictive maintenance. Virtual commissioning uses virtual models to test and validate control systems before physical deployment, reducing errors and downtime. Integration of both enhances manufacturing efficiency by combining dynamic simulation with real-time operational insights.

Table of Comparison

| Feature | Digital Twin | Virtual Commissioning |

|---|---|---|

| Definition | Real-time virtual replica of physical system for monitoring and analysis | Simulation of automation systems to validate control logic before physical commissioning |

| Primary Use | Performance optimization, predictive maintenance, operational insight | Testing and debugging PLC code, machinery integration, reducing startup time |

| Data Input | Real-time sensor data, historical operational data | Control program logic, virtual hardware models |

| Output | Analytics, alerts, system behavior predictions | Validated control sequences, error identification, optimized commissioning process |

| Implementation Stage | Operational phase for continuous monitoring | Pre-commissioning and system integration phase |

| Benefits | Increased uptime, cost savings, improved system reliability | Reduced commissioning errors, faster project delivery, lower risk |

Introduction to Digital Twin and Virtual Commissioning

Digital twins create real-time, dynamic simulations of physical assets by integrating sensor data and advanced analytics to optimize performance and predict maintenance needs. Virtual commissioning uses these digital models to simulate and validate control systems and processes before actual deployment, reducing risks and downtime. Both technologies enhance industrial automation by enabling iterative testing and continuous optimization in a virtual environment.

Core Concepts: Digital Twin Explained

A digital twin is a dynamic, virtual replica of a physical asset, system, or process that utilizes real-time data to mirror its counterpart's status, behavior, and performance. It enables continuous monitoring, simulation, and optimization by integrating sensors, IoT technology, and data analytics to provide a comprehensive digital reflection throughout the asset's lifecycle. Unlike virtual commissioning, which focuses on testing and validating control systems before physical deployment, digital twins offer ongoing insights for predictive maintenance, operational efficiency, and decision-making enhancements.

Understanding Virtual Commissioning in Industrial Engineering

Virtual commissioning in industrial engineering involves using digital twins to simulate and validate control systems before physical implementation, reducing errors and downtime. Digital twins create accurate virtual replicas of machinery and processes, enabling engineers to test and optimize system behavior under various conditions. This approach accelerates deployment, improves system reliability, and lowers costs compared to traditional commissioning methods.

Key Differences Between Digital Twin and Virtual Commissioning

Digital twin and virtual commissioning both utilize simulation technologies but serve distinct purposes; a digital twin provides a real-time, dynamic replica of a physical asset or system for ongoing monitoring and optimization, whereas virtual commissioning focuses on testing and validating control systems in a virtual environment before physical implementation. Digital twins integrate IoT data for continuous feedback, enabling predictive maintenance and operational efficiency improvements, while virtual commissioning reduces project costs and risks by revealing design flaws and control logic errors during the engineering phase. Emphasizing lifecycle integration, digital twins support asset management across the entire operational lifespan, contrasting with virtual commissioning's project-centric approach focused on the pre-production validation stage.

Applications of Digital Twin in Manufacturing Processes

Digital twins in manufacturing enable real-time monitoring and predictive maintenance by creating a dynamic, virtual replica of physical assets and production lines. This technology enhances process optimization, quality control, and operational efficiency by simulating scenarios and analyzing data before implementing changes. Virtual commissioning, while focused on validating control systems and automation software in a simulated environment, complements digital twins by reducing commissioning time and minimizing production downtime.

Virtual Commissioning: Benefits for Production Systems

Virtual commissioning accelerates production system deployment by enabling comprehensive testing and validation of automation processes in a virtual environment. This approach reduces costly physical prototypes, minimizes downtime, and improves system reliability through early error detection. Integration with digital twin technology enhances real-time simulation accuracy, optimizing control logic and equipment performance before actual implementation.

Integration of Digital Twin and Virtual Commissioning

The integration of digital twin and virtual commissioning enhances the accuracy of system simulations by combining real-time data with virtual models, enabling precise testing and validation of automation processes before physical deployment. Digital twins provide continuous synchronization with operational equipment, while virtual commissioning uses these detailed models to simulate and optimize control logic and hardware interactions. This synergy reduces commissioning time, minimizes errors, and improves overall system performance in industrial automation projects.

Challenges in Adopting Digital Twin and Virtual Commissioning

Challenges in adopting digital twin and virtual commissioning include data integration complexities, where real-time data synchronization between physical assets and digital models demands robust IoT infrastructure and advanced analytics. High initial costs and the need for skilled personnel hinder widespread implementation, while issues with model accuracy and scalability limit effective simulation and predictive maintenance. Cybersecurity risks associated with connected systems also present significant barriers to trust and adoption in industrial settings.

Future Trends in Industrial Automation

Digital twin technology enables real-time simulation and monitoring of physical assets, fostering predictive maintenance and enhanced operational efficiency. Virtual commissioning accelerates the integration of automation systems by simulating production processes before physical deployment, reducing startup time and costs. Future trends in industrial automation emphasize the convergence of digital twins and virtual commissioning with AI-driven analytics and IoT connectivity to enable adaptive, self-optimizing manufacturing environments.

Choosing the Right Approach: Digital Twin or Virtual Commissioning

Choosing between digital twin and virtual commissioning depends on project objectives and lifecycle stages; digital twin technology provides continuous real-time data integration for ongoing asset monitoring and optimization, while virtual commissioning focuses on pre-production testing and verification of control systems in a simulated environment. Digital twins enhance predictive maintenance and operational efficiency by mirroring physical assets, whereas virtual commissioning reduces time-to-market and commissioning risks by validating system functionality before physical deployment. Selecting the appropriate approach requires evaluating factors such as implementation cost, system complexity, and long-term operational goals to maximize return on investment and performance reliability.

Cyber-Physical Systems

Digital twins enable real-time synchronization between physical assets and their virtual counterparts, while virtual commissioning leverages Cyber-Physical Systems to test and validate industrial automation processes before physical deployment.

Model-Based Systems Engineering

Digital twin integrates real-time data with virtual commissioning models to enhance Model-Based Systems Engineering by enabling continuous validation and optimization of complex system designs.

Simulation-Based Optimization

Simulation-based optimization enhances digital twins by enabling real-time system performance tuning, whereas virtual commissioning uses simulation to validate control logic before physical implementation.

Real-Time Data Integration

Digital twins provide real-time data integration by continuously synchronizing physical assets with virtual models, enabling more accurate and dynamic monitoring compared to virtual commissioning's primarily static pre-deployment simulations.

Supervisory Control and Data Acquisition (SCADA)

Digital twins provide real-time synchronization with Supervisory Control and Data Acquisition (SCADA) systems for continuous monitoring and optimization, while virtual commissioning simulates SCADA-controlled processes to validate system performance before physical deployment.

Hardware-in-the-Loop (HIL)

Hardware-in-the-Loop (HIL) testing enables virtual commissioning by integrating real hardware components with digital twin simulations for accurate, real-time validation of system performance.

Process Emulation

Digital twin technology enables real-time process emulation by replicating physical system behavior, while virtual commissioning uses process emulation primarily to validate control logic before deploying automation systems.

Smart Manufacturing

Digital twin technology creates a real-time virtual replica of manufacturing processes for continuous monitoring and optimization, while virtual commissioning simulates and tests automation systems before physical deployment, both crucial for enhancing efficiency and reducing downtime in smart manufacturing.

Predictive Maintenance

Digital twins enable predictive maintenance by continuously simulating equipment behavior in real-time, while virtual commissioning primarily focuses on validating control systems before physical deployment.

Industrial IoT (IIoT)

Digital twin technology in Industrial IoT (IIoT) enables real-time data integration and predictive analytics, while virtual commissioning simulates and validates automation systems before physical deployment, optimizing industrial efficiency and reducing downtime.

digital twin vs virtual commissioning Infographic

njnir.com

njnir.com