Demand forecasting predicts future customer demand using historical data and market analysis, enabling companies to anticipate product or service needs accurately. Capacity planning assesses the required production capabilities, machinery, and workforce to meet the forecasted demand efficiently, ensuring resource optimization without overproduction or shortages. Aligning demand forecasting with capacity planning minimizes operational costs and maximizes service levels in industrial engineering processes.

Table of Comparison

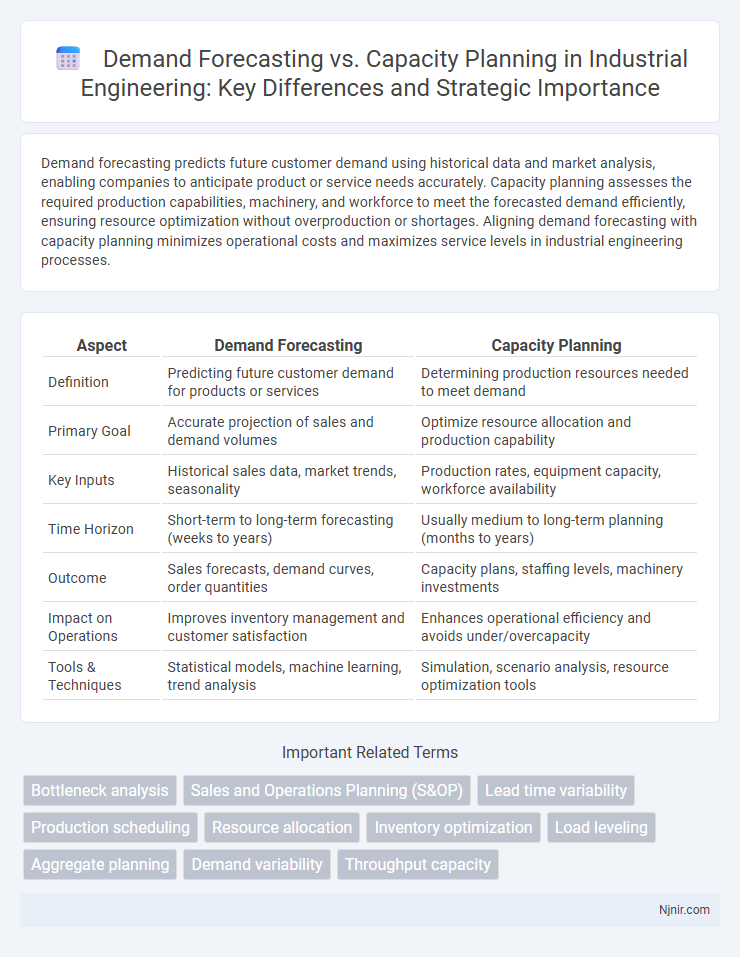

| Aspect | Demand Forecasting | Capacity Planning |

|---|---|---|

| Definition | Predicting future customer demand for products or services | Determining production resources needed to meet demand |

| Primary Goal | Accurate projection of sales and demand volumes | Optimize resource allocation and production capability |

| Key Inputs | Historical sales data, market trends, seasonality | Production rates, equipment capacity, workforce availability |

| Time Horizon | Short-term to long-term forecasting (weeks to years) | Usually medium to long-term planning (months to years) |

| Outcome | Sales forecasts, demand curves, order quantities | Capacity plans, staffing levels, machinery investments |

| Impact on Operations | Improves inventory management and customer satisfaction | Enhances operational efficiency and avoids under/overcapacity |

| Tools & Techniques | Statistical models, machine learning, trend analysis | Simulation, scenario analysis, resource optimization tools |

Introduction to Demand Forecasting and Capacity Planning

Demand forecasting involves predicting future customer demand using historical sales data, market trends, and statistical models to guide inventory management and production schedules. Capacity planning determines the resources, such as labor, machinery, and materials, needed to meet the anticipated demand efficiently without overutilization or underutilization. Integrating accurate demand forecasting with effective capacity planning ensures operational efficiency, reduces costs, and improves customer satisfaction.

Key Definitions: Demand Forecasting vs Capacity Planning

Demand forecasting involves predicting future customer demand based on historical sales data, market trends, and consumer behavior to guide inventory and production decisions. Capacity planning determines the maximum output level a company can achieve by analyzing resources such as labor, equipment, and facilities to meet the forecasted demand efficiently. Both processes are critical for optimizing supply chain performance and minimizing costs in manufacturing and service industries.

Importance in Industrial Engineering

Demand forecasting in industrial engineering predicts future customer demand using historical sales data, market trends, and statistical models, enabling efficient resource allocation. Capacity planning determines the production capability required to meet forecasted demand, optimizing machinery, labor, and workflow to avoid bottlenecks and minimize costs. Together, these processes ensure balanced supply chains, improved operational efficiency, and enhanced decision-making in manufacturing environments.

Methods of Demand Forecasting

Methods of demand forecasting include qualitative techniques such as expert judgment and market research, alongside quantitative models like time series analysis, causal models, and machine learning algorithms. Time series methods analyze historical sales data to identify trends and seasonal patterns, while causal models consider external factors such as economic indicators and marketing activities to predict future demand. Advanced machine learning techniques leverage large datasets to improve forecast accuracy by detecting complex patterns beyond traditional statistical methods.

Techniques of Capacity Planning

Capacity planning techniques include lead strategy, which adds capacity in anticipation of future demand, lag strategy that adds capacity only after demand has increased, and match strategy combining both approaches to balance risks. Quantitative methods such as break-even analysis, capacity requirement planning (CRP), and linear programming are essential for determining optimal resource allocation. These techniques ensure alignment with demand forecasts, optimizing production efficiency, reducing costs, and preventing bottlenecks in operations.

Tools and Technologies Supporting Both Processes

Advanced demand forecasting leverages machine learning algorithms, predictive analytics, and big data platforms to analyze historical sales data, market trends, and customer behavior for accurate future demand predictions. Capacity planning employs simulation software, resource management systems, and cloud-based ERP tools to optimize resource allocation, production schedules, and infrastructure scalability. Integrated platforms like SAP Integrated Business Planning and Oracle Cloud combine demand forecasting and capacity planning functionalities, enabling seamless data synchronization and real-time decision-making.

Challenges in Aligning Demand and Capacity

Demand forecasting faces challenges such as unpredictable market trends and fluctuating customer preferences, which complicate accurate predictions. Capacity planning struggles with adapting resources and infrastructure to meet the uncertain demand, often leading to either overcapacity or shortages. Aligning demand and capacity requires advanced analytics and real-time data integration to minimize mismatches and optimize operational efficiency.

Impact on Operational Efficiency

Demand forecasting leverages historical sales data and market trends to predict future customer demand, enabling businesses to align inventory levels and production schedules accurately. Capacity planning translates these forecasts into actionable resource allocation, ensuring that equipment, labor, and facilities are optimally utilized to meet anticipated demand without overcapacity or bottlenecks. Together, these processes enhance operational efficiency by reducing waste, minimizing stockouts, and improving service levels across supply chain and manufacturing operations.

Case Studies: Successful Demand and Capacity Management

Case studies reveal that companies using integrated demand forecasting and capacity planning achieve up to 20% improvements in operational efficiency and 15% reductions in inventory costs. Amazon's advanced machine learning algorithms accurately predict demand, enabling scalable warehouse capacity adjustments that reduce delivery times by 25%. Similarly, Toyota's use of real-time demand data combined with flexible production capacity has minimized stockouts, enhancing overall supply chain resilience and customer satisfaction.

Future Trends in Forecasting and Planning

Demand forecasting increasingly relies on advanced machine learning algorithms and real-time data integration to improve accuracy and responsiveness. Capacity planning incorporates predictive analytics and IoT-enabled monitoring to dynamically adjust resources and optimize production efficiency. Future trends emphasize the convergence of AI-driven demand sensing with automated capacity optimization for enhanced supply chain resilience and agility.

Bottleneck analysis

Bottleneck analysis in demand forecasting identifies peak demand constraints while in capacity planning it optimizes resource allocation to eliminate production slowdowns.

Sales and Operations Planning (S&OP)

Demand forecasting predicts future sales volumes using historical data and market analysis, while capacity planning ensures production resources align with forecasted demand within Sales and Operations Planning (S&OP) to optimize inventory, reduce costs, and meet customer service targets.

Lead time variability

Demand forecasting estimates future customer demand patterns while capacity planning allocates resources considering lead time variability to minimize production delays.

Production scheduling

Demand forecasting predicts future product demand to optimize production scheduling, while capacity planning ensures available resources meet forecasted demand for efficient production execution.

Resource allocation

Demand forecasting predicts future resource needs by analyzing market trends, enabling accurate capacity planning to optimize resource allocation and minimize operational costs.

Inventory optimization

Demand forecasting predicts future product needs using historical sales data and market trends, while capacity planning allocates resources to meet that demand; together they optimize inventory by balancing stock levels to reduce holding costs and prevent stockouts.

Load leveling

Demand forecasting estimates future customer demand patterns while capacity planning allocates resources accordingly to achieve load leveling and prevent operational bottlenecks.

Aggregate planning

Aggregate planning balances demand forecasting and capacity planning by optimizing production levels, inventory, and workforce to meet projected aggregate demand efficiently.

Demand variability

Demand forecasting analyzes fluctuating customer demand patterns to predict future sales, while capacity planning adjusts resources to efficiently handle demand variability and prevent underutilization or bottlenecks.

Throughput capacity

Throughput capacity in demand forecasting estimates maximum output based on predicted demand, while in capacity planning it determines the actual production capability to meet that demand efficiently.

Demand forecasting vs Capacity planning Infographic

njnir.com

njnir.com