Overall Equipment Effectiveness (OEE) measures the efficiency and productivity of manufacturing equipment, focusing on availability, performance, and quality metrics to identify losses and improve processes. Total Productive Maintenance (TPM) emphasizes proactive and preventive maintenance practices involving all employees to maximize equipment uptime and reliability. While OEE quantifies equipment performance, TPM provides the systematic approach to achieve continuous improvement and sustain high OEE levels in industrial engineering.

Table of Comparison

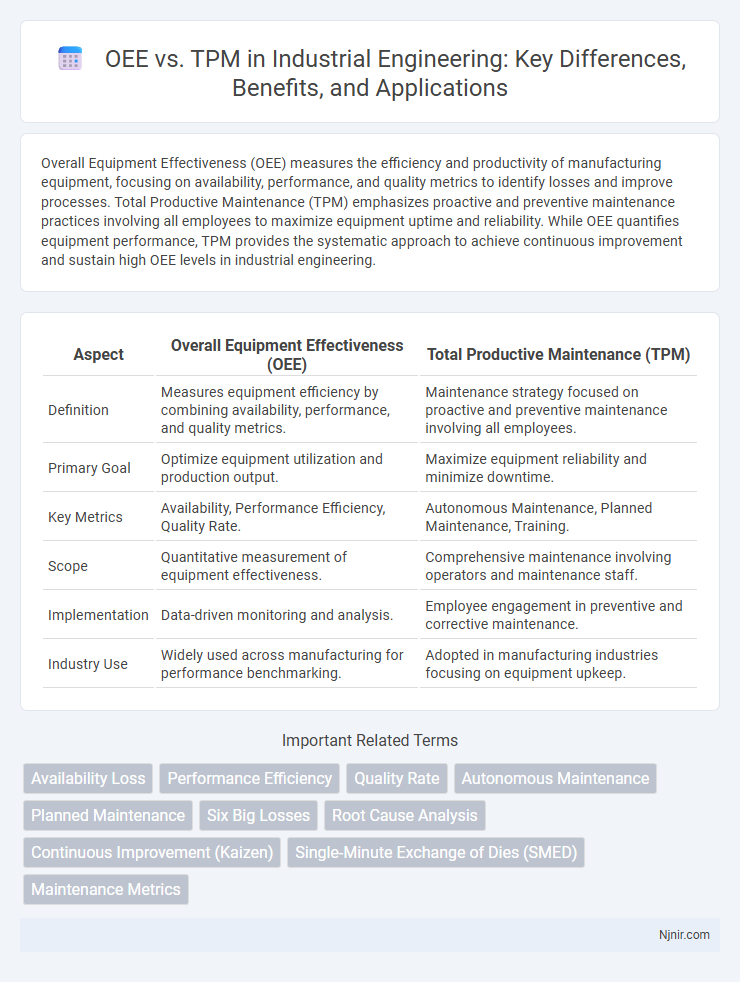

| Aspect | Overall Equipment Effectiveness (OEE) | Total Productive Maintenance (TPM) |

|---|---|---|

| Definition | Measures equipment efficiency by combining availability, performance, and quality metrics. | Maintenance strategy focused on proactive and preventive maintenance involving all employees. |

| Primary Goal | Optimize equipment utilization and production output. | Maximize equipment reliability and minimize downtime. |

| Key Metrics | Availability, Performance Efficiency, Quality Rate. | Autonomous Maintenance, Planned Maintenance, Training. |

| Scope | Quantitative measurement of equipment effectiveness. | Comprehensive maintenance involving operators and maintenance staff. |

| Implementation | Data-driven monitoring and analysis. | Employee engagement in preventive and corrective maintenance. |

| Industry Use | Widely used across manufacturing for performance benchmarking. | Adopted in manufacturing industries focusing on equipment upkeep. |

Understanding OEE and TPM: Core Concepts

Overall Equipment Effectiveness (OEE) measures manufacturing productivity by evaluating availability, performance, and quality to identify losses and optimize equipment usage. Total Productive Maintenance (TPM) emphasizes proactive and preventative maintenance to maximize equipment reliability and involve all employees in continuous improvement. Understanding these core concepts highlights OEE as a performance metric and TPM as a holistic approach to sustain equipment efficiency and reduce downtime.

Key Differences Between OEE and TPM

OEE (Overall Equipment Effectiveness) measures manufacturing productivity by evaluating availability, performance, and quality of equipment, providing a quantifiable efficiency score. TPM (Total Productive Maintenance) is a comprehensive maintenance strategy that emphasizes proactive and preventive maintenance to maximize equipment uptime and involve all employees in continuous improvement. The key difference lies in OEE being a metric to track equipment effectiveness, while TPM is a holistic approach aimed at improving overall equipment reliability and factory performance.

The Role of OEE in Performance Measurement

OEE (Overall Equipment Effectiveness) plays a critical role in performance measurement by quantifying equipment efficiency through availability, performance, and quality metrics. Unlike TPM (Total Productive Maintenance), which emphasizes proactive maintenance and workforce involvement, OEE provides a precise numerical score to identify and prioritize areas for operational improvement. Integrating OEE data helps organizations drive continuous improvement and align maintenance activities with production goals for optimal asset utilization.

How TPM Drives Equipment Reliability

Total Productive Maintenance (TPM) drives equipment reliability by emphasizing proactive and preventive maintenance strategies that reduce unplanned downtime and extend asset lifespan. By involving all employees in maintaining equipment, TPM fosters a culture of continuous improvement and early detection of potential issues, directly enhancing Overall Equipment Effectiveness (OEE) through higher availability and performance rates. Implementing TPM practices results in fewer breakdowns, improved maintenance efficiency, and sustained equipment health, which collectively maximize operational productivity and minimize costs.

Calculating OEE: Essential Metrics and Formulas

Calculating OEE involves measuring Availability, Performance, and Quality to determine the overall equipment effectiveness of manufacturing processes. Availability is calculated by dividing Run Time by Planned Production Time, Performance is the ratio of Ideal Cycle Time times Total Pieces to Run Time, and Quality is the proportion of Good Pieces to Total Pieces produced. These metrics combined produce the OEE score, a key indicator used alongside TPM methodologies to optimize equipment efficiency and reduce downtime.

TPM Pillars and Their Impact on OEE

Total Productive Maintenance (TPM) consists of eight pillars including Autonomous Maintenance, Planned Maintenance, Quality Maintenance, and Education & Training, which collectively enhance equipment reliability and minimize downtime. These pillars directly impact Overall Equipment Effectiveness (OEE) by improving machine availability, performance efficiency, and product quality. Implementing TPM's structured approach drives continuous improvement, leading to higher OEE through reduced unplanned stoppages and optimized maintenance processes.

Integrating OEE and TPM for Operational Excellence

Integrating Overall Equipment Effectiveness (OEE) with Total Productive Maintenance (TPM) enhances operational excellence by combining equipment performance measurement with proactive maintenance strategies. This integration drives continuous improvement by identifying losses in availability, performance, and quality while fostering employee involvement in maintenance activities. Leveraging OEE data within TPM frameworks enables targeted interventions that maximize equipment uptime and productivity, leading to reduced downtime and improved workflow efficiency.

Common Challenges in Implementing OEE and TPM

Common challenges in implementing OEE and TPM include resistance to change from employees, inconsistent data collection, and inadequate training on maintenance best practices. Both OEE and TPM require cultural shifts towards proactive maintenance and continuous improvement, which can be difficult to sustain without strong leadership and clear communication. Data accuracy issues and lack of cross-departmental collaboration often hinder the effectiveness of these methodologies in manufacturing environments.

Case Studies: OEE vs TPM in Real-World Industries

Case studies in manufacturing industries reveal that OEE (Overall Equipment Effectiveness) metrics provide quantifiable data on equipment performance, availability, and quality, enabling precise identification of production bottlenecks. TPM (Total Productive Maintenance) initiatives emphasize workforce involvement and proactive maintenance strategies to enhance equipment reliability and minimize downtime. Industries such as automotive and electronics demonstrate that integrating OEE measurement with TPM practices significantly boosts operational efficiency and reduces maintenance costs.

Best Practices for Maximizing Productivity with OEE and TPM

Maximizing productivity with OEE and TPM involves integrating real-time equipment performance monitoring with proactive maintenance practices to reduce downtime and improve asset reliability. Best practices include continuous data analysis to identify bottlenecks and implementing operator training programs that emphasize equipment care and early problem detection. Aligning OEE metrics with TPM activities ensures a holistic approach to optimizing machine availability, performance efficiency, and product quality.

Availability Loss

Availability Loss in OEE specifically measures downtime due to equipment failures and setup delays, while TPM focuses on proactive maintenance practices to minimize these losses and maximize equipment availability.

Performance Efficiency

OEE measures Performance Efficiency by quantifying actual production speed against ideal cycle time, while TPM enhances Performance Efficiency through proactive equipment maintenance to minimize downtime and maximize operational throughput.

Quality Rate

OEE measures Quality Rate as the percentage of defect-free products, while TPM aims to improve Quality Rate by minimizing equipment failures and defects through proactive maintenance.

Autonomous Maintenance

Autonomous Maintenance in TPM empowers operators to perform routine equipment care, significantly improving OEE by reducing downtime, defects, and cycle time.

Planned Maintenance

Planned Maintenance in TPM systematically reduces equipment downtime, directly enhancing OEE by improving availability and reliability metrics.

Six Big Losses

OEE measures manufacturing efficiency by quantifying the Six Big Losses--equipment failure, setup and adjustment, idling and minor stops, reduced speed, process defects, and rework--while TPM focuses on proactive maintenance to eliminate these losses and maximize equipment effectiveness.

Root Cause Analysis

OEE measures equipment effectiveness by quantifying availability, performance, and quality losses, while TPM emphasizes proactive Root Cause Analysis to prevent breakdowns and improve overall equipment reliability.

Continuous Improvement (Kaizen)

OEE measures equipment efficiency to identify losses, while TPM emphasizes continuous improvement (Kaizen) by involving all employees in proactive maintenance and process optimization.

Single-Minute Exchange of Dies (SMED)

Single-Minute Exchange of Dies (SMED) significantly improves Overall Equipment Effectiveness (OEE) by reducing setup times in Total Productive Maintenance (TPM) programs, thereby increasing machine availability and productivity.

Maintenance Metrics

OEE measures overall equipment efficiency by tracking availability, performance, and quality, while TPM emphasizes proactive maintenance to reduce downtime and improve equipment reliability through metrics like Mean Time Between Failures (MTBF) and Mean Time To Repair (MTTR).

OEE vs TPM Infographic

njnir.com

njnir.com