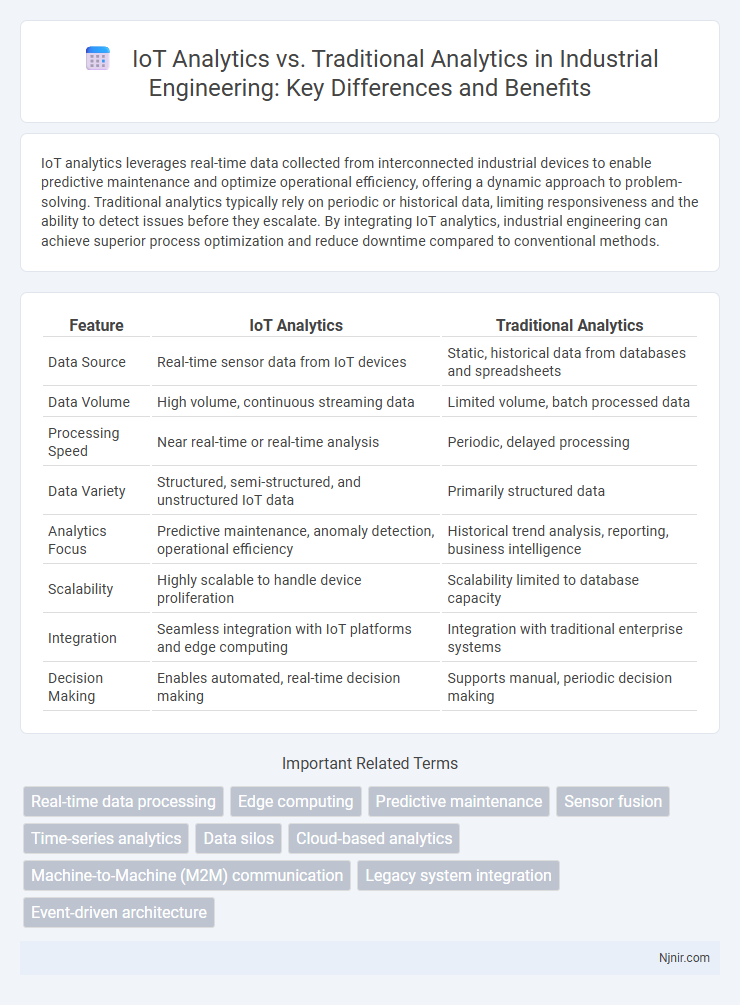

IoT analytics leverages real-time data collected from interconnected industrial devices to enable predictive maintenance and optimize operational efficiency, offering a dynamic approach to problem-solving. Traditional analytics typically rely on periodic or historical data, limiting responsiveness and the ability to detect issues before they escalate. By integrating IoT analytics, industrial engineering can achieve superior process optimization and reduce downtime compared to conventional methods.

Table of Comparison

| Feature | IoT Analytics | Traditional Analytics |

|---|---|---|

| Data Source | Real-time sensor data from IoT devices | Static, historical data from databases and spreadsheets |

| Data Volume | High volume, continuous streaming data | Limited volume, batch processed data |

| Processing Speed | Near real-time or real-time analysis | Periodic, delayed processing |

| Data Variety | Structured, semi-structured, and unstructured IoT data | Primarily structured data |

| Analytics Focus | Predictive maintenance, anomaly detection, operational efficiency | Historical trend analysis, reporting, business intelligence |

| Scalability | Highly scalable to handle device proliferation | Scalability limited to database capacity |

| Integration | Seamless integration with IoT platforms and edge computing | Integration with traditional enterprise systems |

| Decision Making | Enables automated, real-time decision making | Supports manual, periodic decision making |

Overview of IoT Analytics in Industrial Engineering

IoT analytics in industrial engineering leverages real-time sensor data from connected devices to optimize manufacturing processes, predict equipment failures, and enhance operational efficiency. Unlike traditional analytics, which primarily relies on historical data and manual data collection, IoT analytics enables continuous monitoring and automated decision-making through advanced machine learning algorithms and edge computing. This approach reduces downtime, improves resource management, and supports predictive maintenance strategies critical for Industry 4.0 applications.

Traditional Analytics: Foundations and Limitations

Traditional analytics relies heavily on structured data from relational databases and predefined schemas, limiting its ability to process the vast volume and variety generated by IoT devices. It primarily focuses on historical, batch-processed data, which reduces its effectiveness in providing real-time insights critical for IoT environments. The lack of scalability and flexibility in handling streaming data streams restricts traditional analytics from unlocking the full potential of IoT-generated information.

Key Differences Between IoT Analytics and Traditional Analytics

IoT analytics processes real-time data from interconnected devices, enabling timely insights from sensor-generated information, whereas traditional analytics primarily handle static historical data from databases. IoT analytics emphasizes handling massive volumes of streaming data with high velocity and variety, requiring advanced edge computing and AI algorithms, while traditional analytics focus on structured data analysis with batch processing. The key differences lie in data sources, processing speed, and analytical techniques, with IoT analytics designed for real-time decision-making in dynamic environments compared to traditional analytics' retrospective trend analysis.

Data Sources: Real-Time vs. Historical Data

IoT analytics leverages real-time data streams generated from connected devices and sensors, enabling immediate insights and rapid decision-making. Traditional analytics primarily relies on historical data from databases, focusing on analyzing past trends and patterns. The real-time processing capability of IoT analytics allows for dynamic adjustments, while traditional methods emphasize retrospective analysis for strategic planning.

Architecture and Technology Stack Comparison

IoT analytics architecture integrates edge computing, real-time data ingestion, and distributed sensor networks, contrasting with traditional analytics that rely heavily on batch processing and centralized databases. The IoT technology stack includes MQTT, CoAP, time-series databases like InfluxDB, and stream-processing frameworks such as Apache Kafka and Apache Flink, whereas traditional analytics primarily depend on relational databases, ETL tools, and batch-oriented frameworks like Apache Hadoop. This shift supports continuous data flow and immediate insights in IoT environments, enhancing responsiveness compared to the periodic analysis typical in traditional analytics systems.

Scalability and Flexibility in Industrial Applications

IoT analytics offers superior scalability by processing vast real-time data streams from interconnected industrial devices, enabling dynamic adaptation to fluctuating workloads and operational demands. Traditional analytics often rely on batch processing and predefined data sets, limiting flexibility and responsiveness in complex, large-scale industrial environments. The flexible architecture of IoT analytics supports seamless integration with diverse sensors and systems, facilitating scalable decision-making and predictive maintenance in industrial applications.

Impact on Decision-Making Processes

IoT analytics processes real-time data streams from connected devices, enabling faster and more precise decision-making compared to traditional analytics, which relies on historical batch data. This real-time insight significantly enhances predictive maintenance, operational efficiency, and customer experience across industries such as manufacturing, logistics, and smart cities. By leveraging sensor-generated data, IoT analytics empowers organizations to implement proactive strategies, reducing downtime and optimizing resource allocation more effectively than conventional methods.

Predictive Maintenance: IoT Analytics vs. Traditional Methods

IoT analytics leverages real-time sensor data and machine learning algorithms to predict equipment failures with high accuracy, enabling proactive maintenance that reduces downtime and operational costs. Traditional analytics relies on historical data and periodic inspections, often resulting in reactive maintenance schedules and higher risk of unexpected breakdowns. The integration of IoT analytics enhances predictive maintenance by providing continuous monitoring and early anomaly detection, outperforming traditional methods in efficiency and reliability.

Security and Data Privacy Considerations

IoT analytics demands enhanced security measures due to the vast number of interconnected devices generating continuous data streams, increasing attack surfaces compared to traditional analytics reliant on centralized data sources. Data privacy considerations in IoT analytics require real-time encryption, device authentication, and stringent access controls to protect sensitive information transmitted across networks, whereas traditional analytics primarily focus on securing stored data within controlled environments. Compliance with IoT-specific regulations such as GDPR and HIPAA is critical to ensure privacy and security while processing high-velocity, high-volume IoT data versus standard compliance frameworks for conventional analytics.

Future Trends in Industrial Analytics Evolution

Future trends in industrial analytics emphasize the integration of IoT analytics with advanced technologies such as AI, machine learning, and edge computing to process real-time data from connected devices. IoT analytics enables predictive maintenance, asset optimization, and operational efficiency by analyzing vast streams of sensor data, surpassing traditional analytics that rely on historical and batch-processed information. This evolution is driving smart factories and Industry 4.0 initiatives, where continuous, automated insights lead to enhanced decision-making and reduced downtime.

Real-time data processing

IoT analytics enables real-time data processing with continuous sensor data streams, vastly outperforming traditional analytics which relies on batch processing and delayed insights.

Edge computing

IoT analytics leverages edge computing to process data locally on devices, reducing latency and bandwidth usage compared to traditional analytics that rely on centralized cloud processing.

Predictive maintenance

IoT analytics leverages real-time sensor data and machine learning algorithms for predictive maintenance, enabling faster fault detection and reduced downtime compared to traditional analytics relying on historical data alone.

Sensor fusion

Sensor fusion in IoT analytics integrates data from multiple sensor types to enable real-time, context-aware insights, outperforming traditional analytics that often rely on isolated or static data sources.

Time-series analytics

IoT analytics specializes in real-time time-series data processing for continuous sensor streams, while traditional analytics primarily handles static, historical datasets with less emphasis on temporal patterns.

Data silos

IoT analytics breaks down data silos by integrating real-time sensor data from diverse devices into a unified platform, unlike traditional analytics that often struggle with isolated, fragmented data sources.

Cloud-based analytics

Cloud-based IoT analytics leverage scalable real-time data processing and AI-driven insights, surpassing traditional analytics by enabling dynamic, large-scale device monitoring and predictive maintenance across distributed networks.

Machine-to-Machine (M2M) communication

IoT analytics leverages real-time Machine-to-Machine (M2M) communication to process vast streams of sensor data for predictive maintenance, whereas traditional analytics relies on static data sets and human intervention for insight generation.

Legacy system integration

IoT analytics enables seamless integration with legacy systems by using real-time data processing and edge computing, whereas traditional analytics often struggles with static data sources and limited interoperability.

Event-driven architecture

IoT analytics leverage event-driven architecture to process real-time sensor data streams efficiently, while traditional analytics often rely on batch processing of static datasets.

IoT analytics vs Traditional analytics Infographic

njnir.com

njnir.com