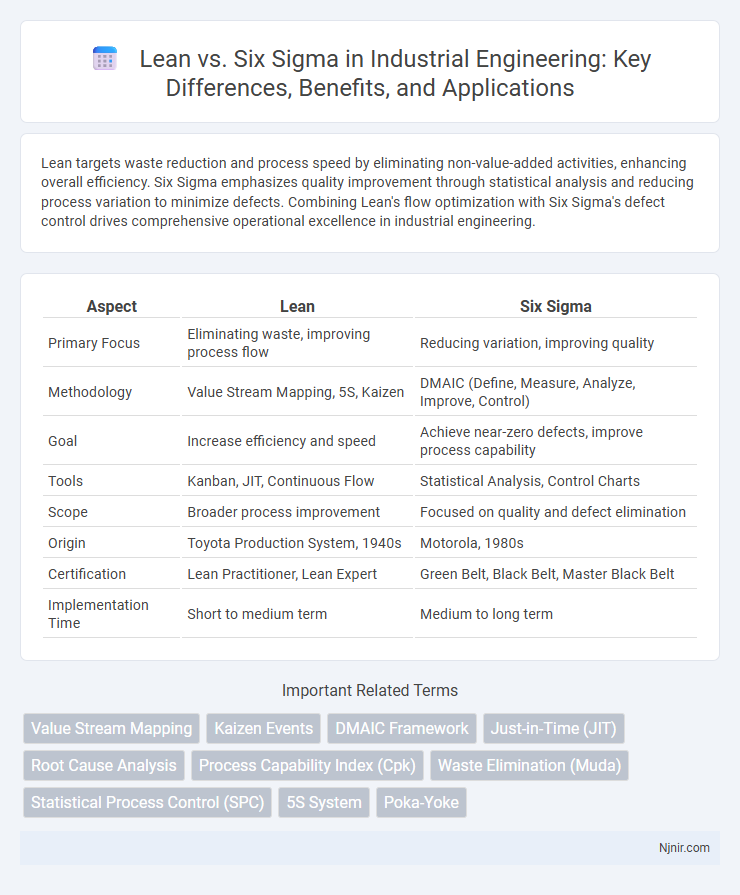

Lean targets waste reduction and process speed by eliminating non-value-added activities, enhancing overall efficiency. Six Sigma emphasizes quality improvement through statistical analysis and reducing process variation to minimize defects. Combining Lean's flow optimization with Six Sigma's defect control drives comprehensive operational excellence in industrial engineering.

Table of Comparison

| Aspect | Lean | Six Sigma |

|---|---|---|

| Primary Focus | Eliminating waste, improving process flow | Reducing variation, improving quality |

| Methodology | Value Stream Mapping, 5S, Kaizen | DMAIC (Define, Measure, Analyze, Improve, Control) |

| Goal | Increase efficiency and speed | Achieve near-zero defects, improve process capability |

| Tools | Kanban, JIT, Continuous Flow | Statistical Analysis, Control Charts |

| Scope | Broader process improvement | Focused on quality and defect elimination |

| Origin | Toyota Production System, 1940s | Motorola, 1980s |

| Certification | Lean Practitioner, Lean Expert | Green Belt, Black Belt, Master Black Belt |

| Implementation Time | Short to medium term | Medium to long term |

Introduction to Lean and Six Sigma

Lean focuses on maximizing value by eliminating waste and optimizing processes, using tools like value stream mapping and continuous flow to improve efficiency. Six Sigma aims to reduce variation and defects through data-driven methodologies and statistical analysis, typically following the DMAIC (Define, Measure, Analyze, Improve, Control) cycle. Both methodologies complement each other to enhance quality and operational performance in diverse industries.

Core Principles of Lean

Lean methodology focuses on eliminating waste, optimizing flow, and delivering value to the customer by maximizing efficiency and minimizing non-value-added activities. Core principles include identifying value from the customer's perspective, mapping the value stream to highlight waste, creating continuous flow, establishing pull-based systems, and pursuing perfection through ongoing improvement. These principles drive reduced lead times, improved quality, and increased operational agility in manufacturing and service environments.

Core Principles of Six Sigma

Six Sigma centers on reducing process variation and improving quality by using data-driven decision making and statistical analysis. Core principles include defining customer requirements, measuring current process performance, analyzing root causes of defects, implementing improvements, and controlling future processes to sustain gains. This methodology aims to achieve near-perfect quality with a target of 3.4 defects per million opportunities.

Key Differences Between Lean and Six Sigma

Lean focuses on eliminating waste and improving process flow to increase efficiency, while Six Sigma targets reducing process variation and improving quality through statistical analysis. Lean emphasizes speed and smooth operations using tools like value stream mapping, whereas Six Sigma relies on data-driven methodologies such as DMAIC (Define, Measure, Analyze, Improve, Control). Integrating Lean and Six Sigma combines waste reduction with defect minimization to optimize overall organizational performance.

Similarities and Overlapping Features

Lean and Six Sigma both aim to improve organizational efficiency by reducing waste and minimizing process variation. Both methodologies emphasize data-driven decision-making, continuous improvement, and customer satisfaction through streamlined processes. Tools such as value stream mapping, root cause analysis, and Kaizen events are commonly used in both Lean and Six Sigma implementations to enhance operational performance.

Tools and Methodologies Comparison

Lean utilizes tools such as value stream mapping, 5S, and Kaizen to eliminate waste and enhance process flow, focusing on improving efficiency and reducing cycle time. Six Sigma employs methodologies like DMAIC (Define, Measure, Analyze, Improve, Control) and statistical tools including control charts and hypothesis testing to reduce process variation and improve quality. Both approaches complement each other by combining Lean's speed and waste reduction with Six Sigma's data-driven quality improvement techniques.

Benefits of Lean and Six Sigma in Industrial Engineering

Lean enhances industrial engineering by streamlining processes, reducing waste, and improving operational efficiency, leading to faster production cycles and lower costs. Six Sigma provides a data-driven approach to quality management, minimizing defects and variability in manufacturing processes, which increases product reliability and customer satisfaction. Combining Lean and Six Sigma empowers industries to optimize performance, boost productivity, and achieve continuous improvement in complex engineering environments.

Implementation Challenges and Solutions

Implementation challenges of Lean vs Six Sigma often include resistance to change, lack of skilled personnel, and inadequate data quality. Lean faces difficulties in sustaining continuous improvement culture, while Six Sigma struggles with complex statistical tools and project prioritization. Solutions involve comprehensive training programs, strong leadership commitment, and integration of Lean Six Sigma methodologies to balance flexibility and data-driven decision-making.

Case Studies: Lean vs. Six Sigma in Industry

Case studies reveal Lean's effectiveness in streamlining manufacturing workflows, such as Toyota's use of Lean principles to reduce waste and enhance production efficiency. Six Sigma's data-driven approach excels in quality control, exemplified by General Electric's implementation of Six Sigma to significantly decrease process defects. Industries benefit from combining Lean's process speed with Six Sigma's precision, optimizing both operational efficiency and product quality.

Choosing the Right Approach for Your Organization

Selecting between Lean and Six Sigma depends on your organization's primary goals: Lean targets waste reduction and process speed, while Six Sigma emphasizes minimizing variability and defects. Consider Lean if improving workflow efficiency and eliminating non-value-added activities is critical. Opt for Six Sigma when high precision and quality control are essential for meeting customer requirements and reducing errors.

Value Stream Mapping

Value Stream Mapping in Lean identifies waste and optimizes flow by visualizing process steps, while Six Sigma integrates it to analyze data-driven improvements and reduce process variation.

Kaizen Events

Kaizen Events in Lean focus on rapid, continuous improvement through employee-driven problem-solving, while Six Sigma integrates Kaizen Events to reduce process variation and enhance quality using data-driven methodologies.

DMAIC Framework

The DMAIC framework in Six Sigma--Define, Measure, Analyze, Improve, Control--systematically improves processes by reducing defects, while Lean focuses on eliminating waste and enhancing flow for operational efficiency.

Just-in-Time (JIT)

Lean emphasizes Just-in-Time (JIT) production to reduce waste and improve flow, while Six Sigma focuses on reducing process variation and defects but can complement JIT by enhancing overall quality and efficiency.

Root Cause Analysis

Lean utilizes root cause analysis to eliminate waste and improve process flow, while Six Sigma applies statistical tools in root cause analysis to reduce variation and defects.

Process Capability Index (Cpk)

Lean improves process flow by eliminating waste, while Six Sigma enhances Process Capability Index (Cpk) by reducing process variation to achieve higher quality performance.

Waste Elimination (Muda)

Lean focuses on eliminating waste (Muda) to improve process flow and efficiency, while Six Sigma targets reducing variation and defects to enhance quality and consistency.

Statistical Process Control (SPC)

Lean emphasizes waste reduction and flow improvement, while Six Sigma focuses on reducing process variation using Statistical Process Control (SPC) to monitor and control quality.

5S System

The 5S System, a key component of Lean methodology, focuses on workplace organization and standardization to improve efficiency and reduce waste, distinguishing it from Six Sigma's data-driven approach to process variation reduction.

Poka-Yoke

Poka-Yoke is a Lean technique that prevents errors by designing fail-safes, complementing Six Sigma's data-driven approach to reducing defects and process variation.

Lean vs Six Sigma Infographic

njnir.com

njnir.com