Digital twin technology offers a dynamic, real-time replica of physical systems, enabling continuous monitoring and optimization in industrial engineering. Simulation models provide predictive analysis based on predefined scenarios but lack live data integration and adaptive feedback. Integrating digital twins with simulation enhances decision-making accuracy and operational efficiency by combining real-time insights with scenario-based evaluations.

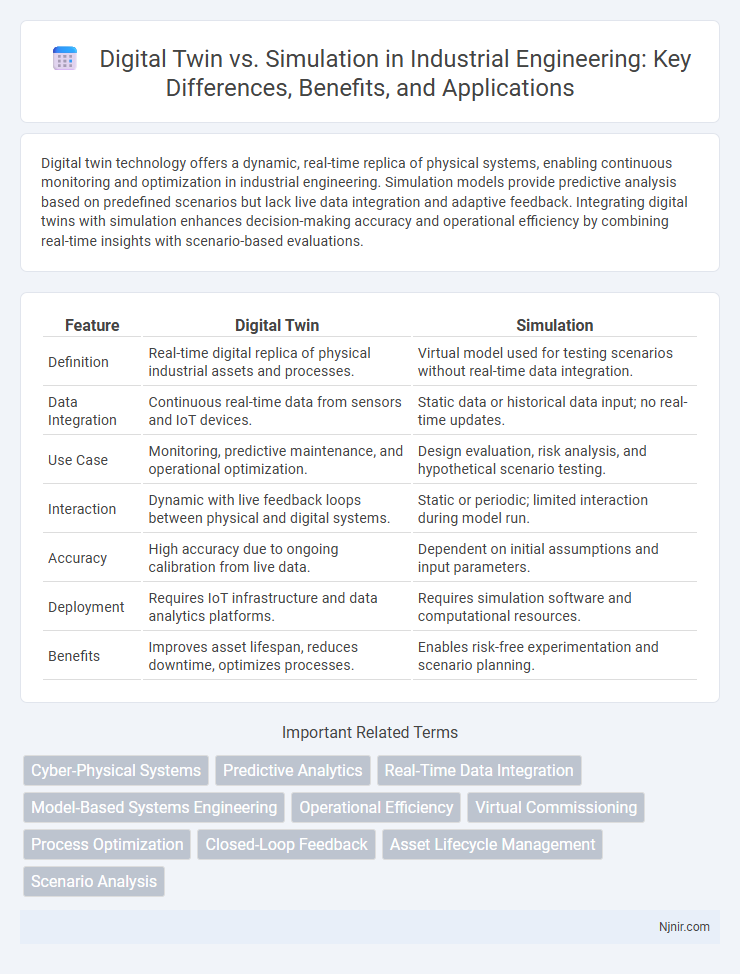

Table of Comparison

| Feature | Digital Twin | Simulation |

|---|---|---|

| Definition | Real-time digital replica of physical industrial assets and processes. | Virtual model used for testing scenarios without real-time data integration. |

| Data Integration | Continuous real-time data from sensors and IoT devices. | Static data or historical data input; no real-time updates. |

| Use Case | Monitoring, predictive maintenance, and operational optimization. | Design evaluation, risk analysis, and hypothetical scenario testing. |

| Interaction | Dynamic with live feedback loops between physical and digital systems. | Static or periodic; limited interaction during model run. |

| Accuracy | High accuracy due to ongoing calibration from live data. | Dependent on initial assumptions and input parameters. |

| Deployment | Requires IoT infrastructure and data analytics platforms. | Requires simulation software and computational resources. |

| Benefits | Improves asset lifespan, reduces downtime, optimizes processes. | Enables risk-free experimentation and scenario planning. |

Defining Digital Twin and Simulation in Industrial Engineering

Digital twin in industrial engineering refers to a real-time, dynamic virtual replica of physical assets, processes, or systems enabling continuous monitoring, analysis, and optimization through data integration from IoT sensors. Simulation involves creating a static or dynamic mathematical model that mimics the behavior of industrial systems under various conditions to predict outcomes and support decision-making without continuous real-time data feedback. Digital twins provide ongoing interaction and adaptive learning capabilities, whereas simulations offer scenario testing primarily based on predefined models and assumptions.

Core Differences Between Digital Twin and Simulation Technologies

Digital twin technology creates a dynamic, real-time virtual replica of a physical asset, system, or process, continuously updated with live data to mirror actual conditions. Simulation technology, by contrast, uses models to analyze hypothetical scenarios and predict outcomes without requiring real-time data integration. The core difference lies in digital twins' emphasis on real-world synchronization and ongoing interaction versus simulation's focus on static, predictive modeling.

Real-Time Data Integration: Digital Twin Advantage

Digital twins continuously integrate real-time data from sensors and IoT devices, providing an up-to-date virtual replica of physical assets, unlike traditional simulations that rely on static or historical data sets. This real-time data integration enables more accurate monitoring, predictive maintenance, and dynamic decision-making. As a result, digital twins offer superior operational insights and responsiveness in complex environments compared to conventional simulation tools.

Applications of Simulation in Industrial Engineering

Simulation in industrial engineering enables the analysis and optimization of manufacturing processes by modeling production lines, resource allocation, and workflow efficiency. It supports decision-making in system design, risk assessment, and process improvements through predictive analytics and scenario testing. Unlike digital twins, which replicate real-time system behavior, simulation primarily focuses on hypothetical scenarios to evaluate potential changes and their impacts before implementation.

Digital Twin Use Cases in Industrial Processes

Digital twins enable real-time monitoring and predictive maintenance in industrial processes by creating dynamic replicas of physical assets, reducing downtime and operational costs. Simulation models, while useful for scenario analysis, lack continuous data integration, limiting their responsiveness in fast-changing environments. Key digital twin use cases include optimizing production lines, improving equipment efficiency, and facilitating remote diagnostics and control.

Scalability and Complexity: A Comparative Analysis

Digital twins offer superior scalability by continuously integrating real-time data from physical assets, enabling dynamic adaptation to complex systems compared to traditional simulations that rely on pre-defined models and static inputs. The complexity handled by digital twins encompasses multi-dimensional data streams, predictive analytics, and system interactions, providing granular insights and operational accuracy beyond the scope of conventional simulation tools. Scalability in digital twins supports large-scale deployments and iterative updates, making them ideal for complex industrial environments where real-time decision-making is crucial.

Data Feedback Loops: Digital Twin vs. Simulation

Digital twins incorporate real-time data feedback loops from physical systems, enabling continuous updates and adaptive decision-making based on live operational conditions. In contrast, simulations use static models with predetermined parameters, lacking dynamic data integration and limiting responsiveness to real-world changes. Data feedback loops in digital twins enhance predictive accuracy and operational efficiency beyond traditional simulation capabilities.

Cost and Resource Implications for Implementation

Digital twin technology typically requires higher upfront investment due to the integration of real-time data sensors, advanced analytics, and continuous monitoring systems, whereas simulation often demands lower initial costs as it focuses on creating models for specific scenarios without continuous data feeds. Resource allocation for digital twins includes ongoing costs related to maintenance, data storage, and system updates, contrasting with simulations that primarily consume resources during model development and testing phases. Choosing between digital twins and simulations significantly impacts operational budgets, with digital twins offering long-term value through enhanced predictive capabilities but requiring more substantial initial and ongoing resource commitments.

Enhancing Predictive Maintenance: Digital Twin Over Simulation

Digital twin technology enhances predictive maintenance by providing real-time data integration and continuous monitoring, enabling more accurate anticipation of equipment failures compared to traditional simulations. Unlike simulations that rely on static models, digital twins dynamically reflect actual operational conditions, improving the precision of maintenance schedules and reducing unplanned downtime. This real-time synchronization with physical assets makes digital twins a superior tool for optimizing asset performance and prolonging machinery lifespan.

Future Trends: Convergence and Divergence in Industrial Digitalization

Digital twin technology advances toward greater convergence with simulation by integrating real-time data and predictive analytics, enabling more precise and dynamic industrial process optimization. However, divergence persists as simulations specialize in scenario testing without physical counterpart dependencies, maintaining distinct roles within digitalization strategies. Future industrial trends emphasize hybrid approaches where digital twins provide continuous system feedback, while simulations explore hypothetical conditions, collectively enhancing decision-making and operational resilience.

Cyber-Physical Systems

Digital twins in cyber-physical systems provide real-time, bidirectional data integration and continuous feedback loops, whereas simulations typically offer static, one-way scenario analyses without dynamic system updates.

Predictive Analytics

Digital twin technology enhances predictive analytics by continuously replicating real-time system data, enabling more accurate forecasting compared to static simulation models.

Real-Time Data Integration

Digital twins enable real-time data integration from physical assets for continuous monitoring and predictive insights, whereas traditional simulations rely on static or historical data without live updates.

Model-Based Systems Engineering

Digital twin integrates real-time data and dynamic feedback within Model-Based Systems Engineering to enable continuous system optimization, whereas simulation primarily relies on static models for predictive analysis without real-time interaction.

Operational Efficiency

Digital twins enhance operational efficiency by providing real-time, dynamic replication of assets for proactive decision-making, whereas simulations offer static, scenario-based analysis without continuous data integration.

Virtual Commissioning

Virtual commissioning leverages digital twins to create accurate real-time replicas of physical systems, enabling precise simulation-based testing and optimization before actual deployment.

Process Optimization

Digital twins provide real-time, dynamic process optimization by continuously integrating live data, whereas traditional simulations rely on static models and predefined scenarios for predictive analysis.

Closed-Loop Feedback

Digital twins integrate real-time closed-loop feedback from physical assets to continuously update simulations, enabling accurate performance optimization compared to conventional one-way simulation models.

Asset Lifecycle Management

Digital twins provide real-time asset lifecycle management by continuously integrating live sensor data to optimize performance and predict maintenance needs, whereas simulations rely on static models for scenario analysis without real-time updates.

Scenario Analysis

Digital twin technology enables real-time scenario analysis by integrating live data for dynamic system modeling, whereas traditional simulation relies on static models for predictive scenario exploration.

Digital twin vs Simulation Infographic

njnir.com

njnir.com