Energy management focuses on monitoring, controlling, and conserving energy consumption to reduce costs and environmental impact within industrial processes. Resource optimization aims to maximize the efficient use of all inputs, including materials, labor, and equipment, to enhance productivity and minimize waste. Integrating energy management with resource optimization leads to sustainable industrial operations and improved overall performance.

Table of Comparison

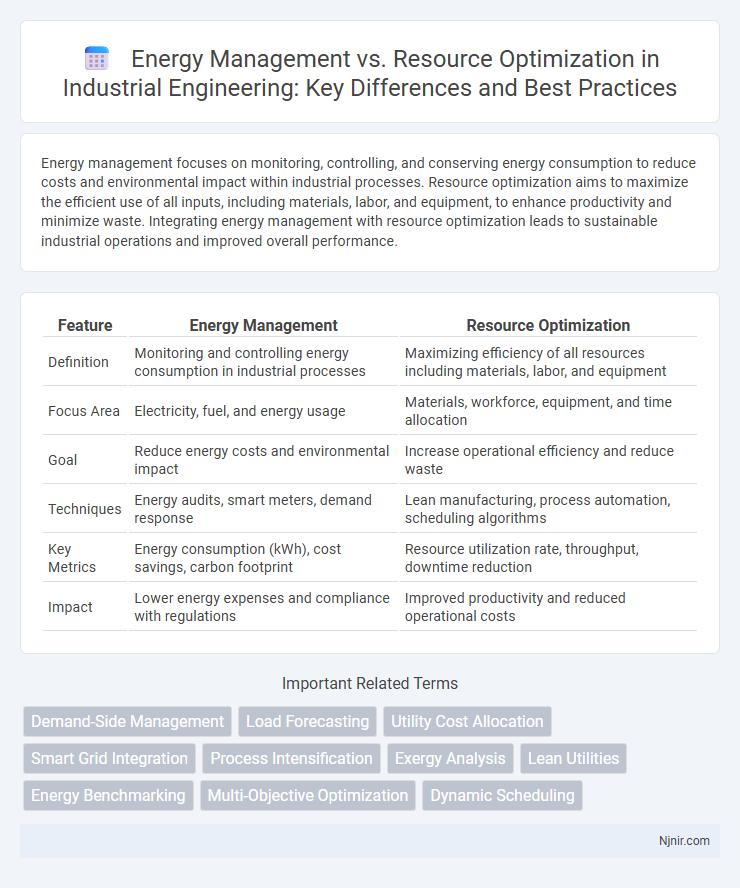

| Feature | Energy Management | Resource Optimization |

|---|---|---|

| Definition | Monitoring and controlling energy consumption in industrial processes | Maximizing efficiency of all resources including materials, labor, and equipment |

| Focus Area | Electricity, fuel, and energy usage | Materials, workforce, equipment, and time allocation |

| Goal | Reduce energy costs and environmental impact | Increase operational efficiency and reduce waste |

| Techniques | Energy audits, smart meters, demand response | Lean manufacturing, process automation, scheduling algorithms |

| Key Metrics | Energy consumption (kWh), cost savings, carbon footprint | Resource utilization rate, throughput, downtime reduction |

| Impact | Lower energy expenses and compliance with regulations | Improved productivity and reduced operational costs |

Understanding Energy Management in Industrial Engineering

Energy management in industrial engineering centers on monitoring, controlling, and conserving energy within manufacturing processes to enhance efficiency and reduce operational costs. It involves the implementation of technologies, such as energy meters and automation systems, alongside strategic planning to identify energy-saving opportunities and minimize waste. Contrastingly, resource optimization encompasses a broader scope, aiming to allocate all resources--including materials, labor, and energy--most effectively to maximize overall production performance.

Defining Resource Optimization in Modern Industries

Resource optimization in modern industries involves the strategic allocation and utilization of assets, materials, and labor to maximize productivity and minimize waste. It integrates advanced technologies like AI and IoT to analyze real-time data and streamline processes, enhancing operational efficiency and sustainability. Effective resource optimization reduces costs and environmental impact while boosting competitive advantage in markets driven by innovation and resource scarcity.

Key Differences: Energy Management vs Resource Optimization

Energy Management focuses specifically on monitoring, controlling, and conserving energy usage within a system or organization to reduce costs and environmental impact. Resource Optimization encompasses a broader scope, aiming to efficiently allocate all types of resources, including labor, materials, and time, to maximize overall productivity and minimize waste. Key differences lie in Energy Management's targeted approach to energy efficiency, while Resource Optimization integrates multiple resources for holistic operational improvement.

Importance of Energy Efficiency in Industrial Processes

Energy management in industrial processes focuses on monitoring and controlling energy consumption to reduce waste and costs, while resource optimization aims at maximizing the efficient use of all inputs, including raw materials and labor. Prioritizing energy efficiency leads to significant reductions in greenhouse gas emissions and operational expenses, aligning with sustainability goals and regulatory compliance. Implementing advanced energy management systems and real-time data analytics enhances process performance and drives continuous improvement in industrial energy usage.

Techniques for Effective Resource Allocation

Techniques for effective resource allocation in energy management include demand forecasting, load balancing, and real-time monitoring to reduce energy waste and improve efficiency. Resource optimization employs methods like linear programming, machine learning algorithms, and stochastic modeling to allocate resources dynamically based on consumption patterns and availability. Integrating these techniques enables precise allocation of energy resources, ensuring cost savings and sustainability in both industrial and commercial sectors.

Impact of Energy Management on Operational Costs

Effective energy management significantly reduces operational costs by minimizing energy waste and enhancing system efficiency in industrial and commercial settings. Implementing smart energy monitoring tools and adopting energy-efficient technologies lead to substantial savings on utility bills and maintenance expenses. These practices also lower carbon footprints, contributing to both economic and environmental sustainability.

Integrating Resource Optimization with Smart Manufacturing

Integrating resource optimization with smart manufacturing enhances energy management by leveraging advanced data analytics and IoT sensors to reduce waste and improve efficiency. Real-time monitoring of production processes enables adaptive energy consumption adjustments, aligning output with demand while minimizing resource usage. This synergy drives sustainable manufacturing practices, reduces operational costs, and supports decarbonization targets in industrial environments.

Technological Innovations in Energy Management Systems

Technological innovations in Energy Management Systems (EMS) have significantly enhanced the ability to monitor and control energy consumption with real-time data analytics and IoT integration, enabling precise energy management across industrial and commercial sectors. Advanced EMS leverage machine learning algorithms and predictive analytics to optimize energy usage, reducing waste and improving operational efficiency beyond traditional resource optimization methods. The incorporation of smart grids, automated demand response, and cloud-based platforms in EMS ensures dynamic energy distribution and supports sustainable energy practices.

Sustainable Practices: Balancing Energy Use and Resource Use

Sustainable practices in energy management emphasize reducing energy consumption through efficient technologies and renewable sources, while resource optimization focuses on the strategic use of materials and minimizing waste in production processes. Balancing energy use and resource utilization requires integrating smart systems that monitor and adapt consumption patterns to enhance sustainability outcomes. Effective synergy between these approaches leads to lower carbon footprints and improved environmental stewardship across industries.

Future Trends in Industrial Energy and Resource Optimization

Future trends in industrial energy and resource optimization emphasize the integration of advanced AI algorithms and IoT sensors to enhance real-time data analytics, enabling precise energy consumption forecasting and resource allocation. Smart grids combined with blockchain technology ensure transparent, decentralized energy transactions, promoting efficient use of renewable energy sources. Digital twins and edge computing facilitate dynamic system modeling and adaptive control, significantly driving sustainability and cost reductions in large-scale industrial operations.

Demand-Side Management

Demand-Side Management enhances Energy Management by optimizing resource use and reducing peak demand through strategic load shifting and efficiency improvements.

Load Forecasting

Load forecasting plays a critical role in energy management by predicting demand to ensure efficient resource optimization and reduce operational costs.

Utility Cost Allocation

Energy management enhances utility cost allocation by monitoring consumption patterns, while resource optimization reduces overall expenses through efficient asset utilization.

Smart Grid Integration

Smart grid integration enhances energy management by enabling real-time monitoring and dynamic load balancing, which drives resource optimization through improved energy efficiency and reduced operational costs.

Process Intensification

Process intensification enhances energy management by optimizing resource utilization to increase efficiency and reduce operational costs in industrial systems.

Exergy Analysis

Exergy analysis enhances energy management by quantifying the quality and usability of energy within systems, enabling more precise resource optimization and reducing irreversibility losses.

Lean Utilities

Lean Utilities enhance energy management by minimizing waste and optimizing resource utilization to improve operational efficiency and sustainability.

Energy Benchmarking

Energy benchmarking plays a crucial role in energy management by providing data-driven comparisons of energy performance that inform resource optimization strategies to reduce consumption and costs.

Multi-Objective Optimization

Multi-objective optimization in energy management integrates resource optimization techniques to balance cost, efficiency, and sustainability objectives simultaneously.

Dynamic Scheduling

Dynamic scheduling in energy management enhances resource optimization by adjusting power distribution in real-time to reduce waste and improve system efficiency.

Energy Management vs Resource Optimization Infographic

njnir.com

njnir.com