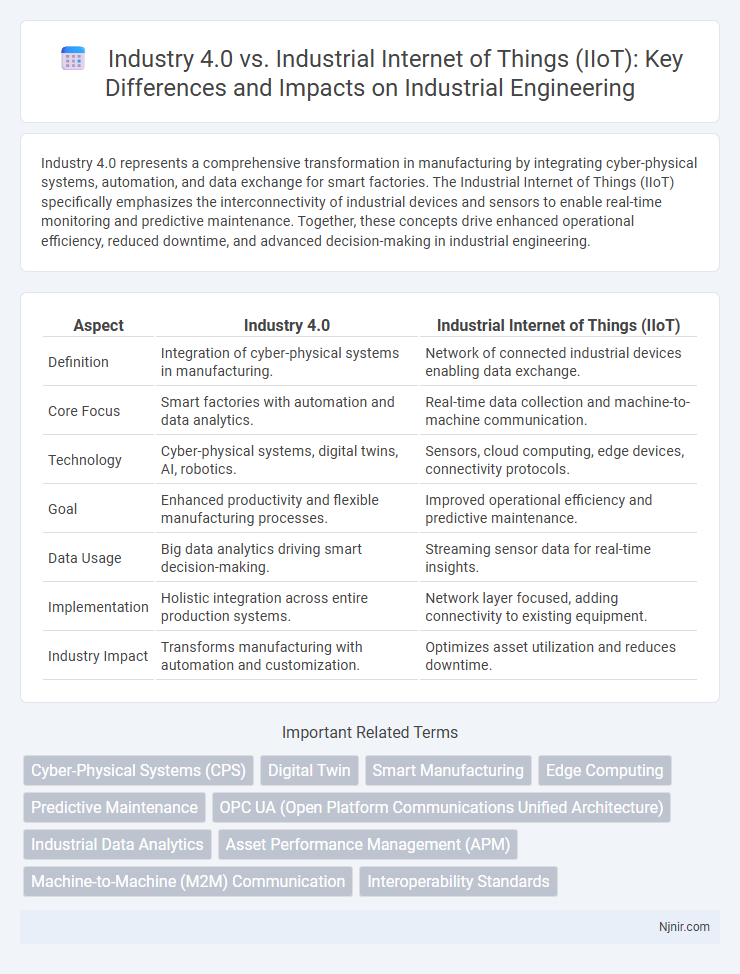

Industry 4.0 represents a comprehensive transformation in manufacturing by integrating cyber-physical systems, automation, and data exchange for smart factories. The Industrial Internet of Things (IIoT) specifically emphasizes the interconnectivity of industrial devices and sensors to enable real-time monitoring and predictive maintenance. Together, these concepts drive enhanced operational efficiency, reduced downtime, and advanced decision-making in industrial engineering.

Table of Comparison

| Aspect | Industry 4.0 | Industrial Internet of Things (IIoT) |

|---|---|---|

| Definition | Integration of cyber-physical systems in manufacturing. | Network of connected industrial devices enabling data exchange. |

| Core Focus | Smart factories with automation and data analytics. | Real-time data collection and machine-to-machine communication. |

| Technology | Cyber-physical systems, digital twins, AI, robotics. | Sensors, cloud computing, edge devices, connectivity protocols. |

| Goal | Enhanced productivity and flexible manufacturing processes. | Improved operational efficiency and predictive maintenance. |

| Data Usage | Big data analytics driving smart decision-making. | Streaming sensor data for real-time insights. |

| Implementation | Holistic integration across entire production systems. | Network layer focused, adding connectivity to existing equipment. |

| Industry Impact | Transforms manufacturing with automation and customization. | Optimizes asset utilization and reduces downtime. |

Defining Industry 4.0 and Industrial Internet of Things (IIoT)

Industry 4.0 represents the fourth industrial revolution characterized by the integration of cyber-physical systems, smart manufacturing, and advanced automation technologies to create interconnected and intelligent production environments. The Industrial Internet of Things (IIoT) refers specifically to the network of interconnected sensors, devices, and machinery within industrial settings, enabling real-time data collection, analytics, and remote control. While Industry 4.0 encompasses a broader transformation of industrial processes and strategies, IIoT serves as a foundational technology facilitating connectivity and data-driven decision-making within Industry 4.0 ecosystems.

Core Technologies in Industry 4.0 and IIoT

Industry 4.0 integrates cyber-physical systems, cloud computing, and artificial intelligence to create smart factories with autonomous decision-making capabilities. The Industrial Internet of Things (IIoT) focuses on interconnected sensors, devices, and machinery, leveraging big data analytics and edge computing for real-time monitoring and predictive maintenance. Key technologies in Industry 4.0 revolve around digital twins and advanced robotics, while IIoT emphasizes interoperability and secure communication protocols for industrial environments.

Historical Evolution: From Automation to Smart Industry

Industry 4.0 emerged in the early 2010s as a comprehensive approach integrating cyber-physical systems, IoT, and cloud computing to create smart factories, while the Industrial Internet of Things (IIoT) specifically emphasizes interconnected industrial devices and sensors for real-time data collection and analytics. The historical evolution began with mechanization and basic automation in the 18th and 20th centuries, progressing to the digitization of manufacturing processes in Industry 3.0, before converging into Industry 4.0 and IIoT that enable predictive maintenance, enhanced operational efficiency, and intelligent decision-making. Major milestones include the introduction of programmable logic controllers (PLCs) in the 1960s, the rise of Internet connectivity in the 1990s, and the development of advanced machine learning algorithms that power IIoT applications today.

Key Similarities: Overlapping Concepts and Practices

Industry 4.0 and the Industrial Internet of Things (IIoT) both emphasize the integration of smart technologies such as sensors, data analytics, and cyber-physical systems to enhance manufacturing efficiency and productivity. Both frameworks rely on interconnected devices and real-time data exchange to enable predictive maintenance, automation, and improved decision-making processes. The overlapping practices include the use of wireless communication protocols, cloud computing, and advanced robotics to create flexible and adaptive industrial environments.

Fundamental Differences in Scope and Focus

Industry 4.0 encompasses a broader transformation integrating cyber-physical systems, smart factories, and data-driven automation across entire manufacturing ecosystems, emphasizing digitalization and interoperability. In contrast, the Industrial Internet of Things (IIoT) specifically concerns the network of connected industrial devices and sensors that collect and exchange data to optimize processes and improve efficiency within those systems. While Industry 4.0 is a holistic framework for smart manufacturing evolution, IIoT serves as a crucial technological component enabling real-time monitoring and advanced analytics.

Data Management and Analytics in Modern Manufacturing

Industry 4.0 integrates cyber-physical systems and smart automation, emphasizing real-time data management and advanced analytics to optimize manufacturing processes. The Industrial Internet of Things (IIoT) focuses on connecting industrial devices and sensors to gather vast amounts of operational data for predictive maintenance and process improvement. Both frameworks leverage big data analytics and machine learning to enhance decision-making, increase efficiency, and reduce downtime in modern manufacturing environments.

Impact on Productivity and Operational Efficiency

Industry 4.0 integrates cyber-physical systems, automation, and data exchange to create smart factories, significantly enhancing productivity through real-time monitoring and adaptive manufacturing processes. The Industrial Internet of Things (IIoT) emphasizes interconnected sensors and devices that collect and analyze data, optimizing operational efficiency by predictive maintenance and minimizing downtime. Both frameworks drive precision, reduce costs, and enable scalable industrial workflows, but Industry 4.0 offers a broader integration of advanced technologies beyond connectivity alone.

Integration Challenges and Implementation Strategies

Industry 4.0 emphasizes the integration of cyber-physical systems, smart factories, and digital twins, while Industrial Internet of Things (IIoT) focuses on connecting industrial devices and sensors to collect and analyze data. Integration challenges include ensuring interoperability among diverse protocols, managing large-scale data security, and overcoming legacy system compatibility issues. Implementation strategies involve adopting standardized communication protocols, deploying edge computing for real-time processing, and utilizing scalable cloud platforms to facilitate seamless data integration and analytics.

Cybersecurity Considerations in Industry 4.0 and IIoT

Cybersecurity considerations in Industry 4.0 and the Industrial Internet of Things (IIoT) emphasize protecting interconnected systems, devices, and data from cyber threats and vulnerabilities. Effective strategies include deploying end-to-end encryption, implementing multi-factor authentication, and continuously monitoring networks for anomalous activities to prevent cyberattacks and data breaches. Securing real-time data communication and ensuring device integrity are critical for maintaining operational continuity and safeguarding industrial intellectual property in these highly integrated environments.

Future Trends and Emerging Opportunities in Industrial Engineering

Industry 4.0 integrates cyber-physical systems and smart factories, emphasizing automation and data exchange, while Industrial Internet of Things (IIoT) focuses on connecting industrial devices for real-time monitoring and analytics. Future trends include advanced AI-driven predictive maintenance, enhanced digital twin technologies, and increased edge computing deployment for low-latency decision-making. Emerging opportunities in industrial engineering center on optimizing supply chains, improving energy efficiency, and developing adaptive manufacturing systems for greater flexibility and scalability.

Cyber-Physical Systems (CPS)

Industry 4.0 integrates Cyber-Physical Systems (CPS) to enable smart manufacturing through real-time data exchange, whereas the Industrial Internet of Things (IIoT) emphasizes interconnected sensors and devices to optimize industrial processes.

Digital Twin

Digital Twin technology in Industry 4.0 enables real-time simulation and predictive maintenance by integrating sensor data from Industrial Internet of Things (IIoT) devices to optimize manufacturing processes.

Smart Manufacturing

Industry 4.0 integrates cyber-physical systems and advanced analytics to enable Smart Manufacturing, while Industrial Internet of Things (IIoT) focuses on connecting industrial devices and sensors to optimize real-time data-driven decision-making.

Edge Computing

Edge computing enhances Industry 4.0 and Industrial Internet of Things (IIoT) by processing data locally on connected devices, reducing latency, improving real-time analytics, and enabling faster decision-making for smart manufacturing systems.

Predictive Maintenance

Industry 4.0 integrates cyber-physical systems and smart manufacturing, while Industrial Internet of Things (IIoT) specifically leverages interconnected sensors and devices to enable predictive maintenance by real-time monitoring and data analytics for early fault detection.

OPC UA (Open Platform Communications Unified Architecture)

OPC UA is a key interoperability standard in Industry 4.0 and Industrial Internet of Things (IIoT), enabling secure, platform-independent communication and seamless integration of heterogeneous industrial devices and systems.

Industrial Data Analytics

Industrial Data Analytics integrates Industry 4.0 and Industrial Internet of Things (IIoT) by leveraging real-time sensor data and advanced algorithms to optimize manufacturing processes and predictive maintenance.

Asset Performance Management (APM)

Industry 4.0 integrates cyber-physical systems and AI to enhance Asset Performance Management, while IIoT focuses on connected sensors and real-time data analytics to optimize asset reliability and predictive maintenance.

Machine-to-Machine (M2M) Communication

Industry 4.0 integrates advanced machine-to-machine (M2M) communication within Industrial Internet of Things (IIoT) frameworks to enable real-time data exchange and automation across smart manufacturing systems.

Interoperability Standards

Industry 4.0 and Industrial Internet of Things (IIoT) both rely on interoperability standards such as OPC UA, MQTT, and ISA-95 to ensure seamless integration, real-time data exchange, and scalable automation across diverse industrial systems.

Industry 4.0 vs Industrial Internet of Things (IIoT) Infographic

njnir.com

njnir.com