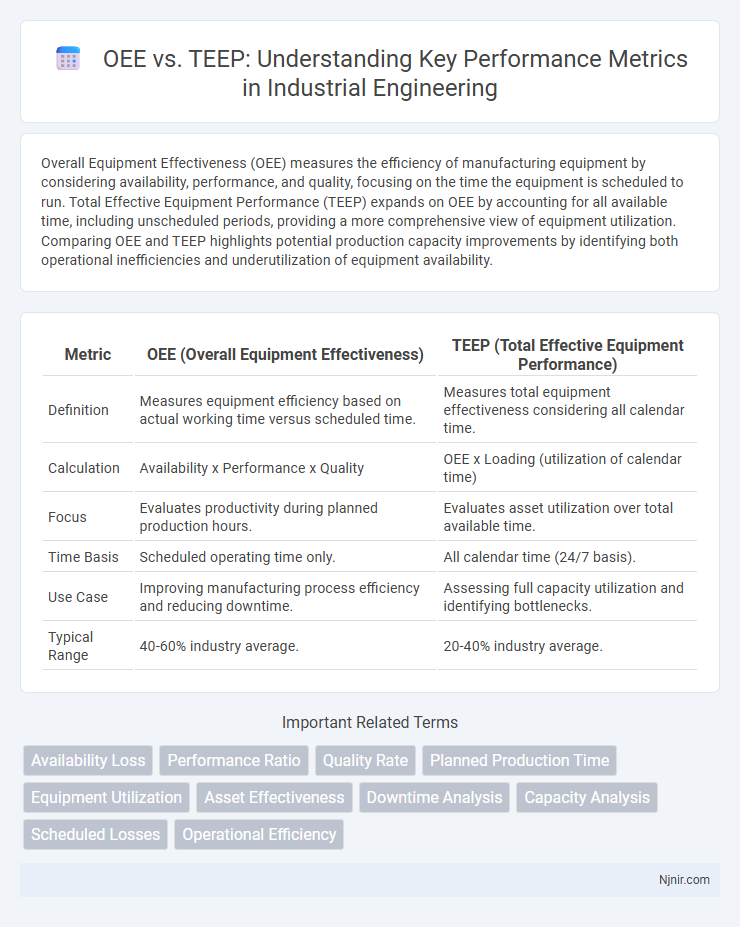

Overall Equipment Effectiveness (OEE) measures the efficiency of manufacturing equipment by considering availability, performance, and quality, focusing on the time the equipment is scheduled to run. Total Effective Equipment Performance (TEEP) expands on OEE by accounting for all available time, including unscheduled periods, providing a more comprehensive view of equipment utilization. Comparing OEE and TEEP highlights potential production capacity improvements by identifying both operational inefficiencies and underutilization of equipment availability.

Table of Comparison

| Metric | OEE (Overall Equipment Effectiveness) | TEEP (Total Effective Equipment Performance) |

|---|---|---|

| Definition | Measures equipment efficiency based on actual working time versus scheduled time. | Measures total equipment effectiveness considering all calendar time. |

| Calculation | Availability x Performance x Quality | OEE x Loading (utilization of calendar time) |

| Focus | Evaluates productivity during planned production hours. | Evaluates asset utilization over total available time. |

| Time Basis | Scheduled operating time only. | All calendar time (24/7 basis). |

| Use Case | Improving manufacturing process efficiency and reducing downtime. | Assessing full capacity utilization and identifying bottlenecks. |

| Typical Range | 40-60% industry average. | 20-40% industry average. |

Understanding OEE: Definition and Components

Overall Equipment Effectiveness (OEE) measures manufacturing productivity by combining Availability, Performance, and Quality to identify production losses. Availability tracks the proportion of scheduled time the equipment is running, Performance assesses speed relative to optimum, and Quality evaluates the ratio of good products produced versus total output. Understanding these components enables targeted improvements to reduce downtime, speed losses, and defects, enhancing operational efficiency.

What is TEEP? Scope and Significance

Total Effective Equipment Performance (TEEP) measures the overall utilization of manufacturing equipment by evaluating actual production time against total calendar time, including planned and unplanned downtime. TEEP's scope encompasses all available time, offering a comprehensive view of capacity utilization, unlike OEE which focuses only on scheduled production time. Its significance lies in identifying hidden capacity reserves and driving strategic decisions to maximize operational efficiency across all shifts and planned downtime periods.

Key Differences Between OEE and TEEP

OEE (Overall Equipment Effectiveness) measures the percentage of manufacturing time that is truly productive based on availability, performance, and quality during planned operating hours. TEEP (Total Effective Equipment Performance) expands this by accounting for all calendar time, including unplanned downtime, to reflect the total potential capacity utilization. Key differences lie in TEEP's inclusion of unplanned downtime and its representation of total equipment utilization, while OEE focuses strictly on efficiency during scheduled production periods.

Calculating OEE: Step-by-Step Guide

Calculating OEE (Overall Equipment Effectiveness) involves measuring Availability, Performance, and Quality to determine how efficiently a manufacturing process operates. Start by calculating Availability as the ratio of Operating Time to Planned Production Time, then find Performance by comparing Actual Production Rate to Ideal Production Rate, and finally, assess Quality through the ratio of Good Units produced to Total Units produced. Multiply these three factors (Availability x Performance x Quality) to obtain the OEE percentage, which reflects the productive efficiency excluding losses, unlike TEEP which accounts for total calendar time.

TEEP Calculation: Expanding the Metrics

TEEP (Total Effective Equipment Performance) calculation expands OEE by incorporating equipment availability across total calendar time, including planned and unplanned downtime. TEEP is determined by multiplying OEE by the equipment's loading rate, representing the maximum capacity utilization over all available time periods. This metric provides a comprehensive view of production efficiency, highlighting both utilization and performance improvements opportunities.

Real-World Applications of OEE in Manufacturing

OEE (Overall Equipment Effectiveness) measures the actual productive time of equipment by accounting for availability, performance, and quality, providing manufacturers with actionable insights to improve line efficiency and reduce downtime. Unlike TEEP (Total Effective Equipment Performance), which assesses total calendar time utilization, OEE focuses on the practical operating time, making it highly applicable for daily production optimization and identifying specific bottlenecks. Real-world applications of OEE in manufacturing include monitoring asset performance in real-time, guiding preventive maintenance schedules, and driving continuous improvement initiatives to maximize output and minimize manufacturing costs.

Leveraging TEEP for Total Production Optimization

Total Effective Equipment Performance (TEEP) extends Overall Equipment Effectiveness (OEE) by accounting for all available calendar time, making it crucial for identifying total production capacity and hidden inefficiencies. Leveraging TEEP enables manufacturers to optimize scheduling, minimize downtime, and maximize asset utilization beyond traditional OEE metrics. This holistic approach drives comprehensive production optimization by aligning equipment performance with actual market demand and operating windows.

Common Pitfalls in OEE and TEEP Analysis

OEE (Overall Equipment Effectiveness) and TEEP (Total Effective Equipment Performance) both measure equipment utilization but often face common pitfalls such as inaccurate data collection and misinterpretation of downtime causes. Inconsistent definitions of availability, performance, and quality metrics can lead to unreliable OEE and TEEP scores, undermining improvement efforts. Overlooking planned downtime in TEEP or failing to differentiate between machine and process losses further distorts the analysis, causing misguided decision-making.

OEE vs TEEP: Which Metric Should You Prioritize?

OEE (Overall Equipment Effectiveness) measures the percentage of planned production time that is truly productive, focusing on availability, performance, and quality during scheduled operations. TEEP (Total Effective Equipment Performance) extends this by including all calendar time, highlighting the full potential utilization of equipment. Prioritize OEE to improve efficiency during operating hours, but use TEEP to identify opportunities for capacity increase by assessing total time utilization.

Integrating OEE and TEEP for Maximum Industrial Efficiency

Integrating Overall Equipment Effectiveness (OEE) and Total Effective Equipment Performance (TEEP) provides a comprehensive approach to maximizing industrial efficiency by measuring both asset utilization and equipment effectiveness. OEE focuses on availability, performance, and quality during planned production time, while TEEP expands this by accounting for calendar time, highlighting capacity utilization opportunities. Combining these metrics enables manufacturers to identify production losses comprehensively and implement targeted strategies to optimize equipment uptime and throughput.

Availability Loss

Availability Loss in OEE measures actual production time lost due to equipment downtime, while TEEP accounts for total calendar time, highlighting the broader impact of availability on overall equipment effectiveness.

Performance Ratio

Performance Ratio measures the speed efficiency of a production process in OEE by comparing actual operating time to ideal run time, while in TEEP it reflects total equipment effectiveness considering both availability and utilization rates.

Quality Rate

Quality Rate in OEE measures the proportion of good units produced relative to total units started, while TEEP incorporates availability to reflect the overall plant effectiveness including total calendar time.

Planned Production Time

OEE measures production efficiency using Operating Time, while TEEP evaluates effectiveness based on Planned Production Time, highlighting the total available time for manufacturing.

Equipment Utilization

OEE measures equipment performance based on availability, performance, and quality, while TEEP captures total equipment utilization by incorporating equipment availability within total calendar time.

Asset Effectiveness

Overall Equipment Effectiveness (OEE) measures asset effectiveness by evaluating availability, performance, and quality against planned production time, while Total Effective Equipment Performance (TEEP) extends this by incorporating utilization across all calendar time, providing a comprehensive view of asset effectiveness.

Downtime Analysis

OEE measures manufacturing efficiency excluding planned downtime, while TEEP includes all downtime, making downtime analysis critical for identifying unplanned losses and improving overall production utilization.

Capacity Analysis

OEE measures actual productive time against planned production time, while TEEP evaluates total utilization by comparing actual production to total calendar time, providing a comprehensive capacity analysis.

Scheduled Losses

Scheduled losses reduce OEE by impacting availability during planned production time, while TEEP accounts for total calendar time, measuring overall equipment utilization including all scheduled downtime.

Operational Efficiency

OEE measures operational efficiency by evaluating actual productive time against planned production time, while TEEP assesses total efficiency by considering calendar time, highlighting opportunities for maximizing asset utilization.

OEE vs TEEP Infographic

njnir.com

njnir.com