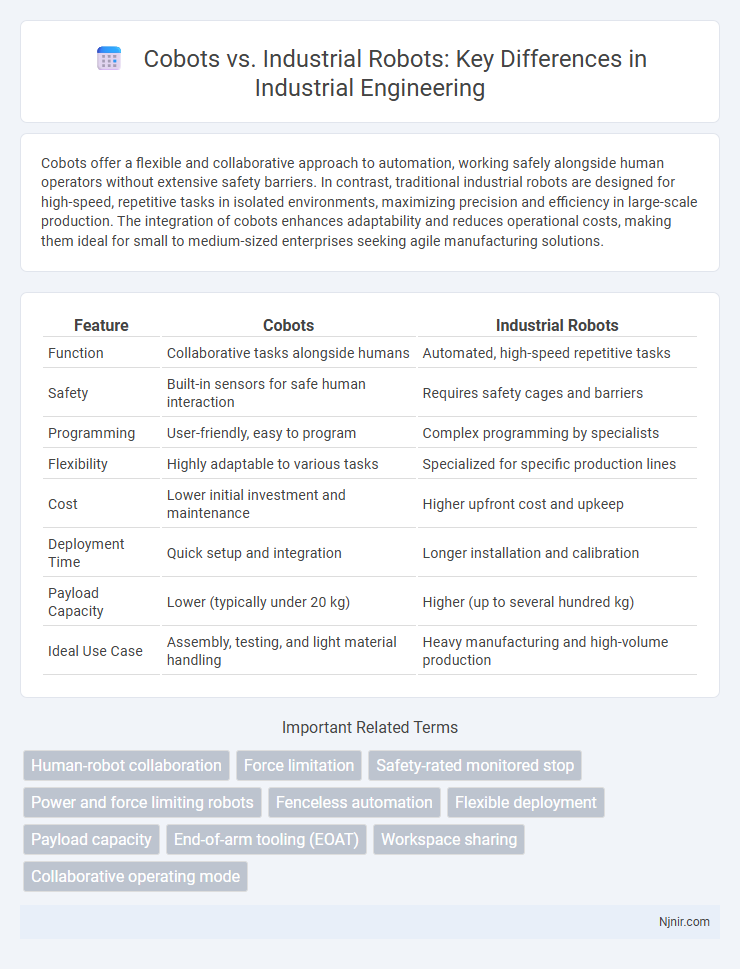

Cobots offer a flexible and collaborative approach to automation, working safely alongside human operators without extensive safety barriers. In contrast, traditional industrial robots are designed for high-speed, repetitive tasks in isolated environments, maximizing precision and efficiency in large-scale production. The integration of cobots enhances adaptability and reduces operational costs, making them ideal for small to medium-sized enterprises seeking agile manufacturing solutions.

Table of Comparison

| Feature | Cobots | Industrial Robots |

|---|---|---|

| Function | Collaborative tasks alongside humans | Automated, high-speed repetitive tasks |

| Safety | Built-in sensors for safe human interaction | Requires safety cages and barriers |

| Programming | User-friendly, easy to program | Complex programming by specialists |

| Flexibility | Highly adaptable to various tasks | Specialized for specific production lines |

| Cost | Lower initial investment and maintenance | Higher upfront cost and upkeep |

| Deployment Time | Quick setup and integration | Longer installation and calibration |

| Payload Capacity | Lower (typically under 20 kg) | Higher (up to several hundred kg) |

| Ideal Use Case | Assembly, testing, and light material handling | Heavy manufacturing and high-volume production |

Introduction to Cobots and Industrial Robots

Cobots, or collaborative robots, are designed to work safely alongside human operators in shared workspaces, featuring advanced sensors and adaptive programming for enhanced flexibility. Industrial robots, typically employed in high-volume manufacturing, perform repetitive tasks with high precision and speed, often operating in isolated environments for safety. Their distinct roles reflect differing priorities: cobots prioritize human-robot interaction and versatility, while industrial robots focus on automation efficiency and durability in structured settings.

Key Differences Between Cobots and Industrial Robots

Cobots, or collaborative robots, are designed to work safely alongside human operators, featuring advanced sensors and flexible motion capabilities, whereas industrial robots operate in isolated environments with high precision and high-speed automation for repetitive tasks. Cobots offer easy programming and adaptability for smaller production runs, while industrial robots excel in heavy-duty applications requiring significant payload capacity and consistent performance. Safety protocols differ, with cobots relying on force-limited joints to prevent injury, contrasting with industrial robots that require physical barriers and safety enclosures.

Safety Standards and Collaborative Workspaces

Cobots are designed with advanced safety standards such as force-limited joints and sensitive sensors that allow safe interaction in collaborative workspaces alongside human operators. Industrial robots typically require physical barriers and safety fencing to prevent human injury, as their operations involve high speed and force in isolated environments. The integration of ISO/TS 15066 guidelines ensures cobots maintain safe collaborative zones, reducing the need for extensive safety enclosures found in traditional robotic applications.

Flexibility and Ease of Integration

Cobots offer superior flexibility by working safely alongside human operators without extensive safety barriers, allowing seamless integration into existing workflows. Industrial robots require significant programming and dedicated safety zones, making them less adaptable to quick changes in production. The ease of integration with cobots significantly reduces downtime and training costs, enhancing overall operational efficiency.

Typical Applications in Industrial Engineering

Cobots excel in collaborative tasks such as assembly, packaging, and quality inspection, enabling safe interaction with human workers on production lines. Industrial robots are typically deployed for heavy-duty operations like welding, material handling, and large-scale machining, where high speed and precision are critical. Integration of cobots enhances flexibility in manufacturing processes, while industrial robots optimize repetitive, high-volume production tasks.

Cost Comparison and Return on Investment

Cobots typically entail lower initial costs ranging from $20,000 to $50,000 compared to industrial robots, which often exceed $100,000 due to their complexity and durability. Although industrial robots offer higher speed and payload capacity, cobots provide faster ROI by minimizing integration expenses and enhancing workforce safety, leading to reduced downtime. Cost efficiency in small to medium enterprises leans toward cobots, while large-scale, high-volume operations may justify the higher investment in traditional industrial robots.

Programming and User Interface

Cobots feature intuitive programming interfaces often based on graphical user interfaces (GUIs) and teach pendants, enabling operators with minimal coding experience to quickly adapt and deploy tasks. Industrial robots typically require advanced programming skills using languages like RAPID, KRL, or ABB's RAPID language, demanding specialized knowledge and longer setup times. The user-friendly design of cobots reduces programming complexity, accelerating integration into collaborative workflows and enhancing operational flexibility.

Payload, Speed, and Performance Capabilities

Cobots typically feature lower payload capacities ranging from 5 to 20 kilograms, designed for precise, collaborative tasks with humans, whereas industrial robots often handle heavier loads exceeding 100 kilograms, optimized for high-speed, repetitive manufacturing processes. Speed in cobots generally maxes out at around 1 to 2 meters per second to ensure safe human interaction, whereas industrial robots can achieve speeds up to 10 meters per second for maximum throughput. Performance capabilities of cobots prioritize flexibility, ease of programming, and safe interaction, while industrial robots excel in heavy-duty, high-precision, and continuous operation environments.

Maintenance and Lifecycle Considerations

Cobots offer easier maintenance and reduced downtime due to their collaborative design, which integrates advanced sensors and safety features allowing for quick troubleshooting and minimal intervention. Industrial robots, while robust and suited for heavy-duty tasks, often require specialized maintenance personnel and longer servicing intervals, which can increase lifecycle costs. Evaluating total cost of ownership involves considering cobots' flexibility and ease of upgrades against industrial robots' durability and lifespan in high-volume production environments.

Future Trends in Robotics for Industrial Engineering

Future trends in robotics for industrial engineering highlight the growing integration of cobots alongside traditional industrial robots, emphasizing enhanced collaboration and flexibility on manufacturing floors. Cobots are increasingly equipped with advanced sensors and AI capabilities, allowing seamless interaction with human workers and real-time adaptation to complex tasks. Industrial robots continue to evolve with higher precision, speed, and automation, driving efficiency in high-volume production while cobots focus on customization and safety in diverse industrial environments.

Human-robot collaboration

Cobots enhance human-robot collaboration by offering adaptive safety features and intuitive interfaces that enable seamless teamwork, unlike traditional industrial robots designed for isolated, high-speed automation tasks.

Force limitation

Cobots use advanced force limitation technology to safely work alongside humans, while traditional industrial robots rely on physical barriers due to higher force outputs.

Safety-rated monitored stop

Safety-rated monitored stop in cobots enables real-time human-robot interaction with immediate halting upon human entry into the workspace, enhancing operational safety compared to traditional industrial robots that rely on fixed barriers and slower emergency stops.

Power and force limiting robots

Power and force limiting cobots enhance safety and collaboration in shared workspaces by dynamically restricting their operating force, whereas traditional industrial robots prioritize high-speed and heavy-duty operations with minimal force constraints.

Fenceless automation

Fenceless automation in cobots enhances flexible human-robot collaboration by enabling safer operation without physical barriers, unlike traditional industrial robots that require rigid safety fences.

Flexible deployment

Cobots enable flexible deployment with easy programming and safe human collaboration, contrasting with industrial robots that require fixed setups and extensive safety measures.

Payload capacity

Cobots typically have a payload capacity ranging from 5 to 25 kilograms, while industrial robots can handle significantly heavier loads, often exceeding 100 kilograms.

End-of-arm tooling (EOAT)

End-of-arm tooling (EOAT) for cobots offers greater flexibility and ease of customization compared to industrial robots, enabling seamless adaptation to diverse tasks in dynamic manufacturing environments.

Workspace sharing

Cobots enable safe, flexible workspace sharing with human operators through advanced sensors and adaptive controls, while industrial robots require dedicated, isolated work areas for operation.

Collaborative operating mode

Cobots operate in a collaborative mode alongside humans with built-in sensors and safety features for shared workspace interaction, whereas industrial robots primarily function autonomously in isolated environments for high-speed, repetitive tasks.

cobots vs industrial robots Infographic

njnir.com

njnir.com