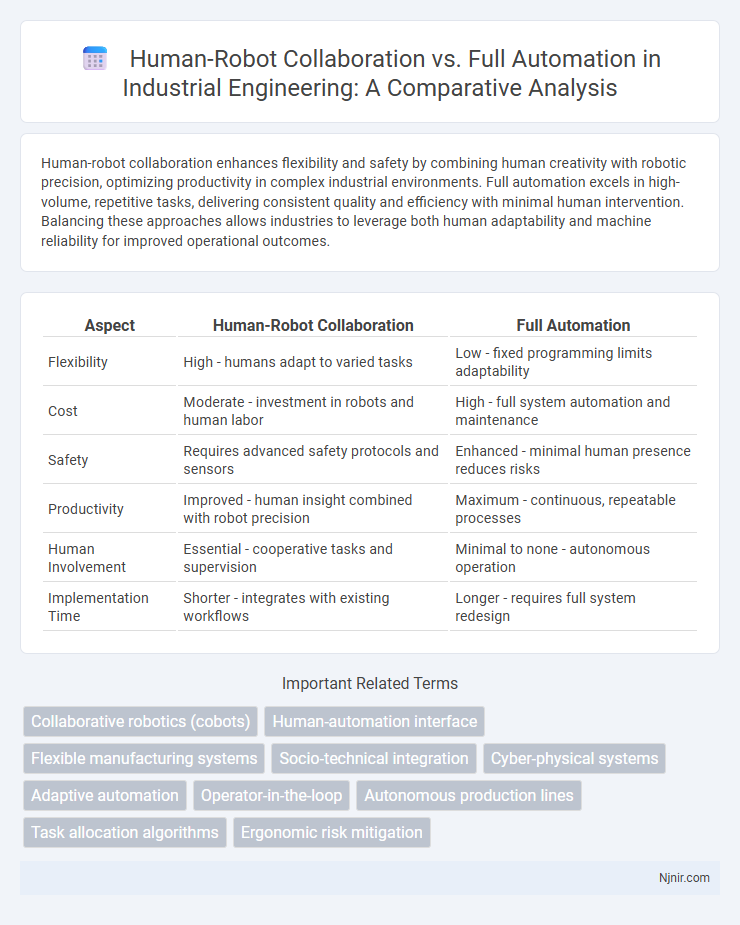

Human-robot collaboration enhances flexibility and safety by combining human creativity with robotic precision, optimizing productivity in complex industrial environments. Full automation excels in high-volume, repetitive tasks, delivering consistent quality and efficiency with minimal human intervention. Balancing these approaches allows industries to leverage both human adaptability and machine reliability for improved operational outcomes.

Table of Comparison

| Aspect | Human-Robot Collaboration | Full Automation |

|---|---|---|

| Flexibility | High - humans adapt to varied tasks | Low - fixed programming limits adaptability |

| Cost | Moderate - investment in robots and human labor | High - full system automation and maintenance |

| Safety | Requires advanced safety protocols and sensors | Enhanced - minimal human presence reduces risks |

| Productivity | Improved - human insight combined with robot precision | Maximum - continuous, repeatable processes |

| Human Involvement | Essential - cooperative tasks and supervision | Minimal to none - autonomous operation |

| Implementation Time | Shorter - integrates with existing workflows | Longer - requires full system redesign |

Introduction to Human-Robot Collaboration and Full Automation

Human-robot collaboration integrates human dexterity and decision-making with robotic precision and endurance, enhancing productivity and safety in manufacturing and service industries. Full automation relies solely on advanced robotics and AI systems to perform tasks without human intervention, aiming to maximize efficiency and reduce operational costs. Both approaches represent distinct pathways to optimize industrial processes, with human-robot collaboration emphasizing synergy and full automation prioritizing complete mechanization.

Key Differences in Workflow Integration

Human-robot collaboration integrates robotic systems with human workers, enhancing flexibility and allowing humans to oversee, intervene, and adapt processes in real time. Full automation relies solely on machines performing tasks with minimal human input, often requiring extensive reconfiguration of workflows to ensure seamless and uninterrupted operation. Workflow integration in collaborative systems emphasizes safety features and intuitive interfaces, whereas full automation focuses on precision, scalability, and optimizing throughput without human intervention.

Efficiency and Productivity Comparisons

Human-robot collaboration enhances efficiency by combining human adaptability with robotic precision, enabling flexible task execution and real-time problem-solving that full automation often lacks. Full automation excels in maximizing productivity through continuous operation and consistent output but may suffer from reduced flexibility in complex or variable environments. Studies indicate that hybrid systems can achieve up to 30% higher efficiency and adaptability compared to fully automated setups, particularly in dynamic manufacturing contexts.

Impact on Workplace Safety

Human-robot collaboration enhances workplace safety by combining robotic precision with human judgment, reducing the risk of accidents in complex tasks. Full automation minimizes human exposure to hazardous environments, significantly lowering injury rates but may introduce new risks related to system failures. Integrating safety protocols and real-time monitoring is crucial to maximizing safety benefits in both approaches.

Cost Implications and Return on Investment

Human-robot collaboration (HRC) often requires lower initial capital investment compared to full automation, as it leverages both human skills and robot efficiency, reducing the need for extensive infrastructure changes. Full automation entails higher upfront costs due to complete system integration, but it can deliver greater long-term savings through continuous operation and minimal labor expenses. Evaluating return on investment (ROI) involves balancing lower immediate expenses and flexibility in HRC against the higher efficiency and potential for significant cost reduction in fully automated systems.

Flexibility and Adaptability in Manufacturing

Human-robot collaboration offers superior flexibility and adaptability in manufacturing by allowing robots to work alongside humans, enabling quick adjustments to changing production needs and complex tasks. Full automation excels in high-volume, repetitive processes but often lacks the agility required for custom or variable manufacturing environments. Integrating human skills with robotic precision enhances responsiveness to unexpected challenges, optimizing workflow efficiency and product quality.

Workforce Skills and Training Requirements

Human-robot collaboration demands workers to develop advanced skills such as robot programming, system monitoring, and adaptive problem-solving to efficiently interact with automated systems. Full automation reduces the need for routine manual tasks but increases the demand for specialized expertise in robotics maintenance, AI management, and cybersecurity. Workforce training must focus on continuous upskilling in technology integration, data analysis, and interdisciplinary knowledge to keep pace with evolving automation environments.

Quality Control and Error Management

Human-robot collaboration enhances quality control by leveraging human judgment alongside robotic precision, allowing for real-time error detection and adaptive decision-making. Full automation relies on predefined algorithms and sensors to maintain consistency, but may struggle with unanticipated errors or nuanced quality deviations that require subjective assessment. Integrating human insights in error management processes reduces false positives and improves overall product quality, making collaboration a superior approach in complex quality control environments.

Ethical and Social Considerations

Human-robot collaboration emphasizes ethical responsibility by preserving human oversight, addressing concerns of job displacement and ensuring accountability in decision-making processes. Full automation raises significant social challenges, including workforce unemployment, loss of human agency, and potential biases embedded within autonomous algorithms. Balancing technological advancement with ethical frameworks is critical to fostering social acceptance and creating equitable labor environments.

Future Trends in Industrial Automation

Human-robot collaboration (HRC) enhances flexibility and safety in manufacturing environments by combining human dexterity with robotic precision, enabling adaptive and efficient workflows. Full automation drives productivity through autonomous systems and AI-driven processes, reducing labor costs but often requiring significant upfront investment and infrastructure. Future trends indicate a hybrid approach where intelligent robots work alongside humans, leveraging advancements in machine learning, sensor technology, and real-time data analytics to optimize operational efficiency and adaptability in Industry 4.0.

Collaborative robotics (cobots)

Collaborative robotics (cobots) enhance human-robot collaboration by enabling safe, adaptable, and efficient teamwork in manufacturing environments, contrasting full automation's fully autonomous, less flexible systems.

Human-automation interface

Advanced human-robot collaboration enhances productivity and safety by integrating intuitive human-automation interfaces that enable real-time communication and adaptive control, whereas full automation relies on autonomous systems with limited human interaction, potentially reducing flexibility and situational awareness.

Flexible manufacturing systems

Human-robot collaboration enhances flexible manufacturing systems by combining adaptive human skills with robotic precision, whereas full automation prioritizes efficiency but often lacks the adaptability required for custom or variable production tasks.

Socio-technical integration

Human-robot collaboration enhances socio-technical integration by combining human adaptability and decision-making with robotic precision, whereas full automation often lacks the nuanced social and technical interaction necessary for dynamic, complex environments.

Cyber-physical systems

Cyber-physical systems enable human-robot collaboration by integrating real-time data exchange and adaptive control, contrasting with full automation's reliance on autonomous decision-making without human intervention.

Adaptive automation

Adaptive automation enhances human-robot collaboration by dynamically adjusting task allocation based on real-time human performance, outperforming full automation in flexibility and efficiency.

Operator-in-the-loop

Human-robot collaboration enhances flexibility and decision-making by maintaining the operator-in-the-loop, whereas full automation eliminates direct human control, potentially reducing adaptability in dynamic environments.

Autonomous production lines

Autonomous production lines integrating human-robot collaboration enhance adaptive flexibility and efficiency compared to full automation by combining human oversight with robotic precision.

Task allocation algorithms

Task allocation algorithms for human-robot collaboration optimize efficiency and safety by dynamically assigning tasks based on human skills and robot capabilities, whereas full automation relies on fixed algorithms designed for autonomous robotic execution without human intervention.

Ergonomic risk mitigation

Human-robot collaboration significantly reduces ergonomic risks by combining robotic precision with human adaptability, whereas full automation eliminates physical strain entirely but may lack flexibility for varied tasks.

Human-robot collaboration vs Full automation Infographic

njnir.com

njnir.com