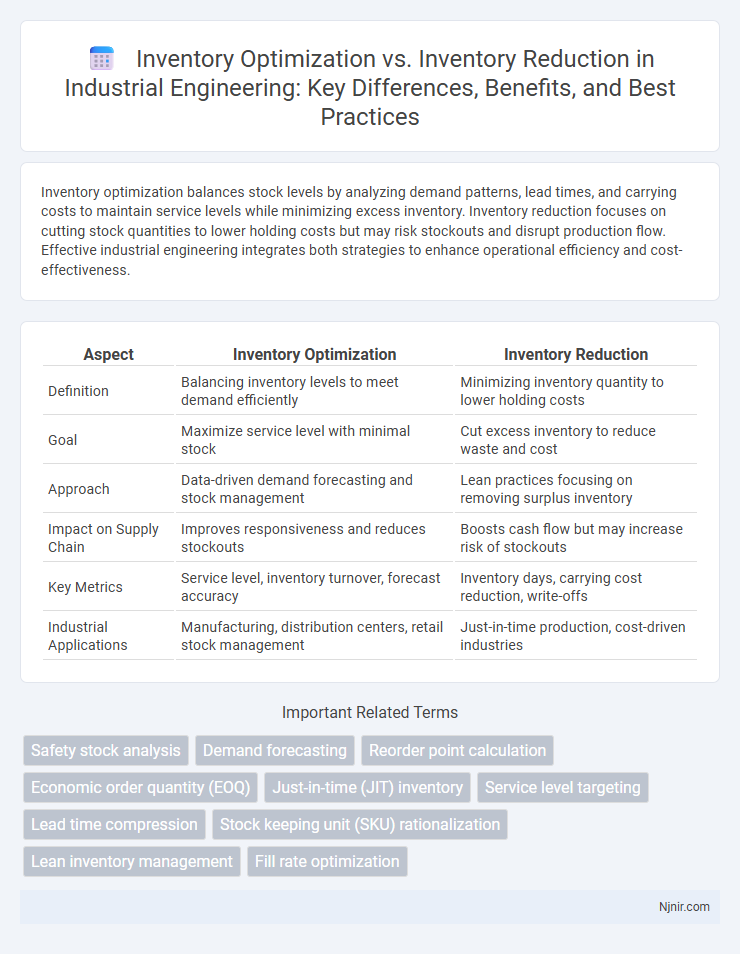

Inventory optimization balances stock levels by analyzing demand patterns, lead times, and carrying costs to maintain service levels while minimizing excess inventory. Inventory reduction focuses on cutting stock quantities to lower holding costs but may risk stockouts and disrupt production flow. Effective industrial engineering integrates both strategies to enhance operational efficiency and cost-effectiveness.

Table of Comparison

| Aspect | Inventory Optimization | Inventory Reduction |

|---|---|---|

| Definition | Balancing inventory levels to meet demand efficiently | Minimizing inventory quantity to lower holding costs |

| Goal | Maximize service level with minimal stock | Cut excess inventory to reduce waste and cost |

| Approach | Data-driven demand forecasting and stock management | Lean practices focusing on removing surplus inventory |

| Impact on Supply Chain | Improves responsiveness and reduces stockouts | Boosts cash flow but may increase risk of stockouts |

| Key Metrics | Service level, inventory turnover, forecast accuracy | Inventory days, carrying cost reduction, write-offs |

| Industrial Applications | Manufacturing, distribution centers, retail stock management | Just-in-time production, cost-driven industries |

Introduction to Inventory Practices in Industrial Engineering

Inventory optimization in industrial engineering involves balancing stock levels to meet production demands while minimizing holding costs, using techniques such as demand forecasting, safety stock calculation, and just-in-time inventory. Inventory reduction aims to streamline materials by eliminating excess or obsolete stock, enhancing cash flow and reducing storage expenses without compromising operational efficiency. Both practices utilize data-driven strategies and supply chain analysis to improve manufacturing productivity and cost management.

Defining Inventory Optimization and Inventory Reduction

Inventory optimization involves strategically managing stock levels to balance supply and demand, minimize holding costs, and improve service levels using data-driven forecasting and replenishment techniques. Inventory reduction focuses on decreasing the total amount of inventory held to cut carrying costs and free up working capital, often by eliminating excess or obsolete stock. Both approaches aim to enhance operational efficiency but differ in scope, with optimization emphasizing equilibrium and reduction targeting quantity minimization.

Key Objectives: Balancing Cost and Service Levels

Inventory optimization aims to balance holding costs and service levels by maintaining the right stock quantities to meet demand without overstocking, while inventory reduction focuses primarily on minimizing inventory levels to cut costs. Effective inventory optimization leverages demand forecasting and safety stock analysis to prevent stockouts and excess inventory, ensuring high service levels. Inventory reduction can risk service disruptions if not carefully managed, whereas optimization prioritizes a strategic equilibrium between cost efficiency and customer satisfaction.

Methods and Tools for Inventory Optimization

Inventory optimization utilizes advanced forecasting algorithms, demand planning software, and real-time analytics tools to balance stock levels and improve supply chain efficiency. Techniques such as ABC analysis, economic order quantity (EOQ), and just-in-time (JIT) inventory management enhance accuracy in meeting demand while minimizing holding costs. Contrarily, inventory reduction focuses primarily on cutting excess stock without employing comprehensive tools that ensure service level optimization.

Common Approaches to Inventory Reduction

Common approaches to inventory reduction include just-in-time (JIT) inventory systems, demand forecasting accuracy, and supplier lead time optimization, all aiming to minimize excess stock while meeting customer demand. Inventory optimization leverages data analytics and real-time monitoring to balance stock levels and reduce carrying costs without jeopardizing service levels. Techniques such as cycle counting and ABC analysis support both strategies by identifying slow-moving items and prioritizing inventory management efforts.

Impact on Supply Chain Performance

Inventory optimization enhances supply chain performance by balancing stock levels to meet demand without overstocking, reducing carrying costs, and improving order fulfillment rates. In contrast, inventory reduction focuses on minimizing stock quantities, which can lead to lower holding costs but risks stockouts and supply disruptions if demand forecasting is inaccurate. Effective inventory management requires aligning optimization strategies with demand variability and lead times to sustain service levels and operational agility.

Risks and Trade-offs: Optimization vs Reduction

Inventory optimization balances stock levels to meet demand while minimizing carrying costs, reducing the risk of stockouts and excess inventory. Inventory reduction aggressively cuts stock quantities, which can lead to cost savings but increases the risk of supply chain disruptions and lost sales. The trade-off involves balancing service levels and operational efficiency against potential risks of insufficient inventory.

Case Studies: Real-World Applications

Case studies in inventory optimization demonstrate enhanced demand forecasting and dynamic stock level adjustments, leading to lower holding costs and improved service rates. Inventory reduction case studies often highlight the impact of lean management techniques and just-in-time (JIT) systems, showing significant reductions in excess stock and waste. Companies like Toyota and Walmart showcase how tailored strategies in inventory management drive operational efficiency and cost savings in real-world settings.

Technological Solutions Driving Inventory Strategies

Technological solutions such as AI-driven demand forecasting and real-time inventory tracking enable precise inventory optimization, balancing stock levels to meet customer demand without overstocking. Inventory reduction focuses on minimizing excess stock and associated carrying costs through automation and advanced analytics, targeting leaner supply chains. Tools like IoT sensors and machine learning models enhance both strategies by providing data-driven insights that improve decision-making and operational efficiency.

Best Practices and Future Trends in Inventory Management

Inventory optimization focuses on balancing stock levels to meet demand while minimizing costs, employing advanced analytics and AI-driven forecasting to enhance accuracy and responsiveness. In contrast, inventory reduction emphasizes minimizing stock quantities to free up capital and reduce holding costs but risks stockouts if not carefully managed. Best practices combine real-time data integration, demand sensing technologies, and collaborative supply chain strategies, with future trends pointing towards increased automation, machine learning, and blockchain for transparent, agile inventory management.

Safety stock analysis

Safety stock analysis ensures inventory optimization maintains service levels by accurately balancing buffer quantities, unlike inventory reduction which primarily cuts stock without considering demand variability.

Demand forecasting

Demand forecasting enhances inventory optimization by accurately aligning stock levels with anticipated customer demand, whereas inventory reduction primarily focuses on minimizing stock without necessarily improving forecast precision.

Reorder point calculation

Accurate reorder point calculation enhances inventory optimization by balancing stock availability and carrying costs, whereas inventory reduction solely aims to minimize stock levels without considering demand variability.

Economic order quantity (EOQ)

Economic order quantity (EOQ) balances inventory optimization by minimizing total holding and ordering costs, whereas inventory reduction focuses primarily on lowering stock levels without necessarily optimizing order quantities.

Just-in-time (JIT) inventory

Just-in-time (JIT) inventory focuses on inventory optimization by minimizing stock levels to reduce holding costs while ensuring timely replenishment, contrasting with inventory reduction that prioritizes cutting quantities without necessarily improving supply chain efficiency.

Service level targeting

Inventory optimization balances stock levels to achieve target service levels while minimizing costs, whereas inventory reduction focuses solely on cutting stock quantity, often risking service level decline.

Lead time compression

Lead time compression enhances inventory optimization by enabling faster replenishment cycles, whereas inventory reduction focuses solely on minimizing stock levels without addressing supply chain responsiveness.

Stock keeping unit (SKU) rationalization

SKU rationalization enhances inventory optimization by aligning stock levels with demand patterns, whereas inventory reduction focuses solely on decreasing overall stock quantities without considering SKU profitability or customer preferences.

Lean inventory management

Lean inventory management emphasizes inventory optimization by balancing stock levels to minimize waste and meet demand efficiently, whereas inventory reduction solely focuses on decreasing stock quantities without necessarily improving overall operational flow.

Fill rate optimization

Inventory optimization improves fill rate by balancing stock levels with demand accuracy, while inventory reduction risks lowering fill rates by minimizing safety stock and increasing stockouts.

Inventory optimization vs Inventory reduction Infographic

njnir.com

njnir.com