Vertical integration streamlines industrial engineering processes by combining successive production stages, enhancing control over supply chains and reducing costs. Horizontal integration focuses on expanding at the same stage of production to increase market share and operational capacity, optimizing resource utilization. Both strategies improve industrial efficiency but target different areas of growth and competitive advantage.

Table of Comparison

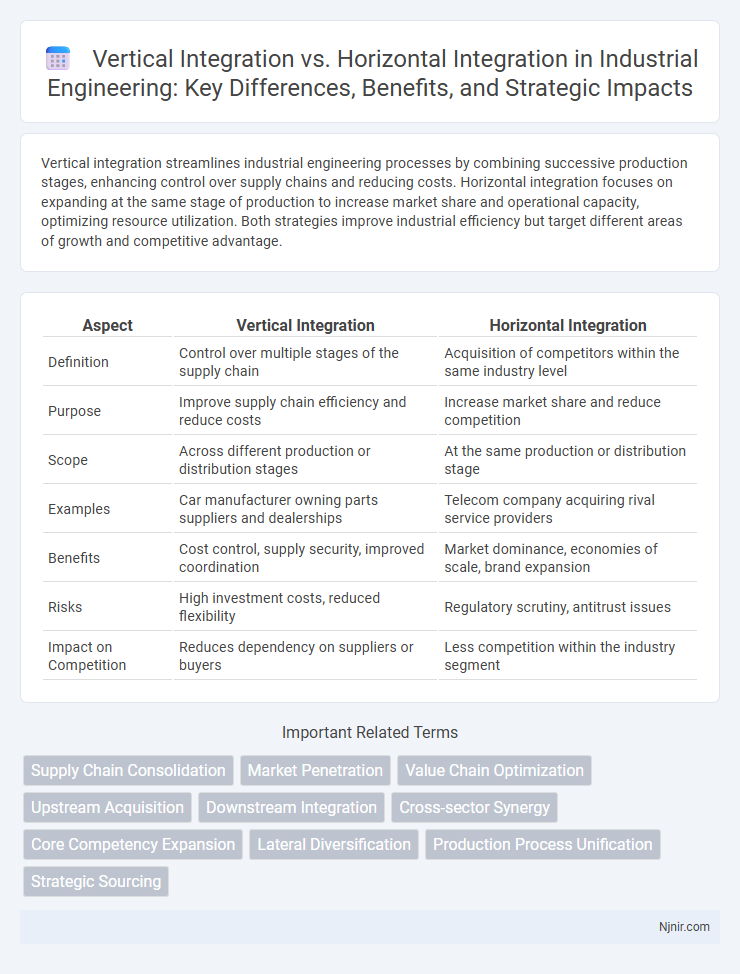

| Aspect | Vertical Integration | Horizontal Integration |

|---|---|---|

| Definition | Control over multiple stages of the supply chain | Acquisition of competitors within the same industry level |

| Purpose | Improve supply chain efficiency and reduce costs | Increase market share and reduce competition |

| Scope | Across different production or distribution stages | At the same production or distribution stage |

| Examples | Car manufacturer owning parts suppliers and dealerships | Telecom company acquiring rival service providers |

| Benefits | Cost control, supply security, improved coordination | Market dominance, economies of scale, brand expansion |

| Risks | High investment costs, reduced flexibility | Regulatory scrutiny, antitrust issues |

| Impact on Competition | Reduces dependency on suppliers or buyers | Less competition within the industry segment |

Introduction to Vertical and Horizontal Integration in Industrial Engineering

Vertical integration involves a company expanding its operations within its supply chain, such as a manufacturer acquiring raw material suppliers or distributors to control production stages, reduce costs, and improve efficiency. Horizontal integration occurs when a company acquires or merges with competitors operating at the same stage of the production process to increase market share, reduce competition, and achieve economies of scale. Industrial engineering applies these integration strategies to optimize workflow, resource allocation, and operational processes for enhanced productivity and competitive advantage.

Defining Vertical Integration: Concepts and Examples

Vertical integration refers to a company's expansion by acquiring or merging with businesses at different stages of the supply chain, such as suppliers or distributors, to gain greater control over production and distribution processes. Examples include Apple controlling both hardware manufacturing and retail operations or Tesla producing batteries and vehicles in-house. This strategy enhances operational efficiency, reduces costs, and improves supply chain coordination by consolidating key functions under one corporate umbrella.

Understanding Horizontal Integration: Key Characteristics

Horizontal integration involves the consolidation of companies operating within the same industry and at the same stage of production, aiming to increase market share and reduce competition. Key characteristics include expansion through mergers or acquisitions of competitors, economies of scale, and enhanced market power. This strategy often leads to improved operational efficiency, greater control over pricing, and a broader customer base.

Strategic Objectives of Vertical Integration

Vertical integration aims to enhance supply chain control by acquiring or merging with suppliers or distributors, reducing dependency on external entities and improving operational efficiency. Strategies focus on cost reduction, improved product quality, and faster time-to-market through streamlined production processes. Companies also seek to increase market power and competitive advantage by controlling multiple stages of the value chain.

Strategic Objectives of Horizontal Integration

Horizontal integration aims to increase market share and reduce competition by acquiring or merging with companies operating at the same level of the value chain. This strategy enhances economies of scale, expands product offerings, and improves bargaining power with suppliers and customers. Companies pursuing horizontal integration seek to strengthen their market position and drive revenue growth through synergy realization and improved operational efficiency.

Advantages and Disadvantages of Vertical Integration

Vertical integration offers advantages such as increased control over the supply chain, improved production efficiency, and reduced costs by eliminating intermediaries. However, it also presents disadvantages including high capital investment, reduced flexibility to adapt to market changes, and potential inefficiencies from managing diverse operations outside a company's core expertise. Companies like Tesla exemplify successful vertical integration by controlling battery production and vehicle assembly, enhancing innovation and cost management.

Pros and Cons of Horizontal Integration

Horizontal integration allows companies to increase market share rapidly by acquiring or merging with competitors, leading to economies of scale, reduced competition, and enhanced bargaining power with suppliers. However, this strategy can result in regulatory scrutiny due to antitrust concerns, potential cultural clashes between merged entities, and the risk of overextension if the integration is poorly managed. Despite these challenges, successful horizontal integration can strengthen a firm's market position and improve operational efficiency.

Impact on Supply Chain Management

Vertical integration enhances supply chain management by consolidating control over multiple stages of production and distribution, resulting in improved coordination, reduced lead times, and decreased dependency on external suppliers. Horizontal integration expands market share by merging with competitors or similar businesses, often leading to economies of scale and stronger bargaining power with suppliers but may complicate supply chain coordination due to increased organizational complexity. Companies leveraging vertical integration tend to achieve more streamlined and resilient supply chains, while horizontal integration emphasizes market dominance and resource optimization across similar production levels.

Challenges and Risks in Implementation

Vertical integration faces challenges such as high capital investment, increased operational complexity, and potential regulatory scrutiny for monopolistic practices. Horizontal integration risks include cultural clashes, antitrust issues, and difficulties in achieving synergies across merged entities. Both strategies can lead to reduced flexibility and increased management burden, impacting long-term business agility.

Comparing Vertical vs Horizontal Integration: Which Suits Your Industry?

Vertical integration involves expanding a company's control over multiple stages of the supply chain, improving efficiency and reducing dependency on suppliers, while horizontal integration focuses on acquiring or merging with competitors within the same industry to increase market share and reduce competition. Industries with complex supply chains, such as automotive or technology, often benefit from vertical integration to streamline production and reduce costs, whereas consumer goods or media industries may find horizontal integration more advantageous for consolidating market presence and leveraging economies of scale. Understanding the specific operational challenges and competitive landscape of your industry is crucial for determining whether vertical or horizontal integration will yield better growth and profitability outcomes.

Supply Chain Consolidation

Vertical integration consolidates supply chains by controlling multiple production stages, while horizontal integration strengthens supply chains by merging companies at the same stage.

Market Penetration

Vertical integration enhances market penetration by controlling supply chains and improving product quality, while horizontal integration expands market share by acquiring competitors and increasing customer base.

Value Chain Optimization

Vertical integration enhances value chain optimization by controlling multiple production stages, while horizontal integration improves economies of scale by expanding within the same industry level.

Upstream Acquisition

Vertical integration emphasizes upstream acquisition to control supply chains, while horizontal integration targets competitors within the same industry level for market expansion.

Downstream Integration

Downstream integration in vertical integration enhances control over distribution channels, improving market reach and customer service compared to the market expansion focus of horizontal integration.

Cross-sector Synergy

Vertical integration enhances cross-sector synergy by streamlining supply chains and fostering collaboration across production stages, whereas horizontal integration maximizes cross-sector synergy through market expansion and resource consolidation across similar industries.

Core Competency Expansion

Vertical integration expands core competencies by enhancing control over supply chain processes, while horizontal integration grows core competencies through market share increase and diversification within the same industry.

Lateral Diversification

Lateral diversification involves expanding a company's product lines or markets through horizontal integration by acquiring or partnering with firms in unrelated industries, enhancing revenue streams and reducing risks.

Production Process Unification

Vertical integration streamlines production process unification by controlling multiple stages within the supply chain, while horizontal integration consolidates similar production processes across different companies to increase efficiency and market share.

Strategic Sourcing

Vertical integration streamlines strategic sourcing by controlling multiple supply chain stages, while horizontal integration enhances strategic sourcing through expanded market reach and supplier networks.

Vertical Integration vs Horizontal Integration Infographic

njnir.com

njnir.com