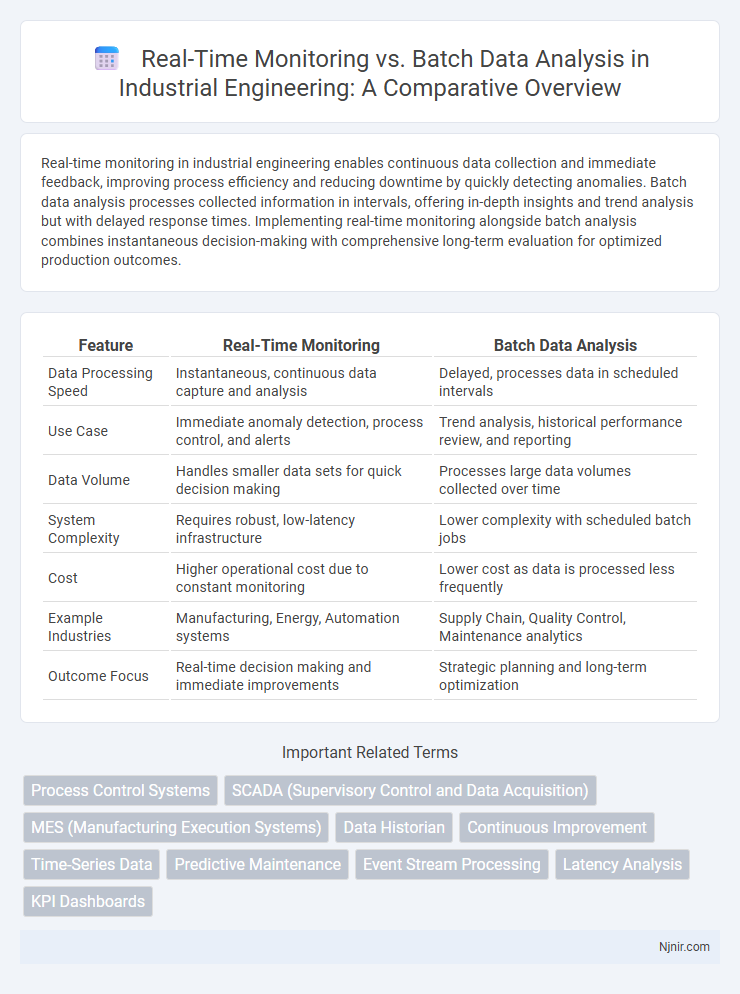

Real-time monitoring in industrial engineering enables continuous data collection and immediate feedback, improving process efficiency and reducing downtime by quickly detecting anomalies. Batch data analysis processes collected information in intervals, offering in-depth insights and trend analysis but with delayed response times. Implementing real-time monitoring alongside batch analysis combines instantaneous decision-making with comprehensive long-term evaluation for optimized production outcomes.

Table of Comparison

| Feature | Real-Time Monitoring | Batch Data Analysis |

|---|---|---|

| Data Processing Speed | Instantaneous, continuous data capture and analysis | Delayed, processes data in scheduled intervals |

| Use Case | Immediate anomaly detection, process control, and alerts | Trend analysis, historical performance review, and reporting |

| Data Volume | Handles smaller data sets for quick decision making | Processes large data volumes collected over time |

| System Complexity | Requires robust, low-latency infrastructure | Lower complexity with scheduled batch jobs |

| Cost | Higher operational cost due to constant monitoring | Lower cost as data is processed less frequently |

| Example Industries | Manufacturing, Energy, Automation systems | Supply Chain, Quality Control, Maintenance analytics |

| Outcome Focus | Real-time decision making and immediate improvements | Strategic planning and long-term optimization |

Introduction to Real-Time Monitoring and Batch Data Analysis

Real-time monitoring involves continuous data collection and immediate analysis to provide instant insights, enabling quick decision-making and rapid response to changing conditions. Batch data analysis processes large volumes of data collected over a period, allowing in-depth examination and trend identification but with delayed results. While real-time monitoring supports operational efficiency and real-time alerting, batch analysis is essential for strategic planning and comprehensive data evaluation.

Key Concepts: Definitions and Differences

Real-time monitoring involves continuous data collection and immediate processing to provide instant insights and rapid response, crucial for applications like fraud detection and system health tracking. Batch data analysis processes large volumes of data collected over a period, optimizing for comprehensive aggregation and trend identification, often used in business intelligence and reporting. Key differences include latency, with real-time monitoring prioritizing low-latency data processing, while batch analysis focuses on deeper historical data examination and resource efficiency.

Advantages of Real-Time Monitoring in Industrial Engineering

Real-time monitoring in industrial engineering enables immediate detection of system anomalies, facilitating prompt corrective actions that minimize downtime and enhance operational efficiency. Continuous data collection supports predictive maintenance by identifying equipment wear patterns before failures occur, reducing maintenance costs and extending asset lifespan. Real-time insights improve process optimization, allowing industries to swiftly adapt to changing conditions and maximize productivity.

Benefits and Limitations of Batch Data Analysis

Batch data analysis enables processing large volumes of data efficiently, making it suitable for historical trend identification and comprehensive reporting. Its benefits include cost-effectiveness and simplified resource management, but limitations involve delayed insights and reduced responsiveness compared to real-time monitoring. Organizations relying on batch analysis may struggle with timely decision-making in fast-changing environments.

Use Cases: When to Apply Real-Time Monitoring

Real-time monitoring is essential in use cases requiring immediate response such as fraud detection in financial transactions, patient health tracking in medical devices, and dynamic pricing in e-commerce platforms. Batch data analysis suits scenarios like historical trend analysis, large-scale report generation, and business intelligence where data processing latency is acceptable. Applying real-time monitoring enhances operational efficiency and risk management by enabling instant anomaly detection and decision-making based on live data streams.

Use Cases: Optimal Scenarios for Batch Data Analysis

Batch data analysis is ideal for processing large volumes of historical data where immediate insights are not critical, such as financial reporting, trend analysis, and customer segmentation. This method excels in scenarios requiring comprehensive data aggregation and complex computation without the constraints of latency. Industries like retail, healthcare, and marketing use batch analysis to generate periodic reports, identify long-term patterns, and drive strategic decisions based on accumulated data.

Data Accuracy and Decision-Making Speed

Real-time monitoring enables continuous data collection and immediate processing, ensuring high data accuracy by detecting anomalies as they occur, which significantly accelerates decision-making speed. Batch data analysis processes large volumes of accumulated data at scheduled intervals, potentially delaying insights and affecting the timeliness of decisions despite often offering thorough accuracy through comprehensive historical data evaluation. Organizations prioritizing rapid, precise decisions benefit from real-time systems, whereas batch analysis suits scenarios requiring in-depth trend analysis over extended periods.

Technological Requirements and Infrastructure

Real-time monitoring demands low-latency data processing technologies such as stream processing frameworks (Apache Kafka, Apache Flink) and edge computing infrastructure to enable instantaneous insights and rapid decision-making. Batch data analysis relies on high-throughput storage systems (Hadoop HDFS, Amazon S3) and distributed computing platforms (Apache Spark, MapReduce) optimized for processing large volumes of historical data with flexible scheduling. Infrastructure for real-time systems typically integrates in-memory databases and event-driven architectures, whereas batch systems prioritize cost-effective scalability and fault tolerance in data warehouses or data lakes.

Integration Challenges in Industrial Environments

Real-time monitoring in industrial environments demands seamless integration of sensors, edge devices, and control systems with minimal latency, posing significant connectivity and data compatibility challenges. Batch data analysis requires consolidating large datasets from diverse sources, often leading to difficulties in harmonizing inconsistent data formats and temporal discrepancies. Overcoming these integration challenges is crucial for achieving accurate, timely insights and optimizing industrial processes.

Future Trends: Convergence of Real-Time and Batch Analysis

The future of data processing emphasizes the convergence of real-time monitoring and batch data analysis, leveraging the strengths of both methods for enhanced decision-making. Advances in hybrid architectures and AI-driven analytics platforms enable seamless integration, allowing businesses to process high-velocity data streams alongside large volumes of historical data. This convergence supports more accurate predictive insights, faster anomaly detection, and improved operational efficiency across industries such as finance, healthcare, and manufacturing.

Process Control Systems

Real-time monitoring in Process Control Systems enables immediate detection and correction of anomalies, enhancing operational efficiency, while batch data analysis processes large datasets periodically for trend identification and long-term performance optimization.

SCADA (Supervisory Control and Data Acquisition)

SCADA real-time monitoring enables instantaneous detection and response to industrial system anomalies, whereas batch data analysis processes collected data periodically for in-depth trend evaluation and optimization.

MES (Manufacturing Execution Systems)

Real-time monitoring in MES enables instant detection and response to production anomalies, while batch data analysis provides comprehensive historical insights for long-term process optimization and strategic decision-making.

Data Historian

Data Historian enhances real-time monitoring by continuously capturing and storing time-stamped process data, enabling instant analysis and rapid decision-making, whereas batch data analysis processes accumulated data periodically, limiting immediate insight into operational conditions.

Continuous Improvement

Real-time monitoring enables continuous improvement by providing instant data insights that facilitate immediate adjustments, whereas batch data analysis offers periodic evaluations that support long-term strategic refinements.

Time-Series Data

Real-time monitoring of time-series data enables immediate anomaly detection and decision-making, while batch data analysis processes historical time-series data for in-depth trend identification and forecasting.

Predictive Maintenance

Real-time monitoring enhances predictive maintenance by providing instantaneous equipment data for immediate anomaly detection, while batch data analysis processes historical data to identify long-term trends and optimize maintenance schedules.

Event Stream Processing

Event Stream Processing enables real-time monitoring by continuously analyzing high-velocity data streams, whereas batch data analysis processes accumulated data sets at scheduled intervals, resulting in delayed insights.

Latency Analysis

Real-time monitoring offers latency as low as milliseconds enabling immediate anomaly detection, whereas batch data analysis incurs latency from minutes to hours due to periodic processing intervals.

KPI Dashboards

Real-time monitoring provides instantaneous KPI dashboard updates enabling immediate decision-making, whereas batch data analysis processes KPI data in intervals, offering comprehensive but delayed insights.

Real time monitoring vs Batch data analysis Infographic

njnir.com

njnir.com