Cellular manufacturing groups different machines into cells to produce similar products efficiently, enhancing workflow and reducing lead times. Job shop manufacturing handles custom or small batch production with highly flexible equipment, allowing for varied and complex tasks but often resulting in longer processing times. Cellular manufacturing boosts productivity through streamlined processes, while job shops prioritize versatility to meet diverse customer demands.

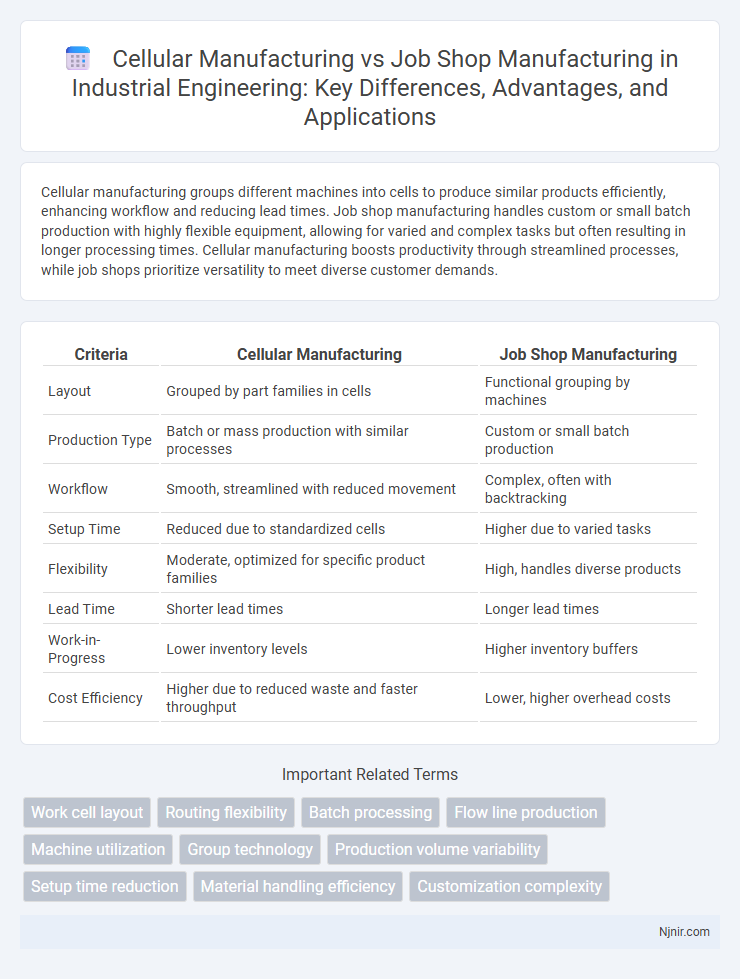

Table of Comparison

| Criteria | Cellular Manufacturing | Job Shop Manufacturing |

|---|---|---|

| Layout | Grouped by part families in cells | Functional grouping by machines |

| Production Type | Batch or mass production with similar processes | Custom or small batch production |

| Workflow | Smooth, streamlined with reduced movement | Complex, often with backtracking |

| Setup Time | Reduced due to standardized cells | Higher due to varied tasks |

| Flexibility | Moderate, optimized for specific product families | High, handles diverse products |

| Lead Time | Shorter lead times | Longer lead times |

| Work-in-Progress | Lower inventory levels | Higher inventory buffers |

| Cost Efficiency | Higher due to reduced waste and faster throughput | Lower, higher overhead costs |

Overview of Cellular Manufacturing and Job Shop Manufacturing

Cellular manufacturing organizes workstations into cells, each dedicated to producing a family of similar products, enabling streamlined workflows and reduced setup times. Job shop manufacturing handles small batches of custom products with highly flexible equipment arranged by function, suitable for diverse and complex tasks. Cellular manufacturing emphasizes efficiency through product-flow orientation, while job shops prioritize customization and adaptability.

Core Principles and Workflow Structure

Cellular manufacturing organizes workstations into small, self-contained units called cells, each dedicated to producing a specific family of parts, enhancing flow efficiency and minimizing waste. Job shop manufacturing arranges resources by function, handling custom, low-volume orders with diverse routing, which leads to variable workflows and higher setup times. Core principles of cellular manufacturing emphasize continuous flow, reduced lead time, and team responsibility, whereas job shops focus on flexibility, customization, and resource sharing.

Layout Design and Material Flow

Cellular manufacturing features a U-shaped or linear layout design that groups machines based on product families, optimizing material flow through reduced handling and minimal movement between workstations. In contrast, job shop manufacturing employs a functional layout where similar machines are grouped together, resulting in complex and variable material flow paths with longer transportation times. The streamlined flow in cellular layouts enhances efficiency and reduces lead times, whereas job shop layouts offer flexibility but often face challenges in material flow coordination.

Flexibility and Customization Capabilities

Cellular manufacturing optimizes flexibility by grouping machines into cells dedicated to specific product families, enabling rapid changeovers and efficient handling of moderate customization levels. Job shop manufacturing offers superior customization capabilities by allowing highly individualized production runs with diverse operations, but this often results in longer lead times and lower flexibility in volume changes. The choice between the two hinges on balancing the need for agile production flows in cellular setups against the extensive customization potential inherent in job shop environments.

Production Efficiency and Throughput

Cellular manufacturing improves production efficiency by organizing workstations into cells that handle related tasks, minimizing movement and reducing setup times compared to the varied workflow in job shop manufacturing. Throughput is enhanced in cellular manufacturing due to streamlined processes and balanced workloads within cells, while job shops often experience bottlenecks and longer lead times caused by batch processing and flexible resource allocation. This results in cellular manufacturing delivering faster cycle times and higher output rates, making it more suitable for medium-volume production environments than the highly customized, lower-volume focus of job shops.

Inventory Management Strategies

Cellular manufacturing reduces work-in-progress inventory by organizing production into dedicated cells, enhancing flow and minimizing delays compared to job shop manufacturing. Job shop manufacturing requires higher inventory levels due to its varied, customized production runs and longer setup times, increasing holding and carrying costs. Implementing pull-based inventory strategies like Kanban in cellular setups improves material turnover and responsiveness, while job shops often rely on push systems to manage highly variable workloads.

Labor Utilization and Skill Requirements

Cellular manufacturing optimizes labor utilization by grouping machines and workers into cells to produce similar products, enhancing workflow efficiency and reducing idle time. It demands multi-skilled labor capable of operating various machines within the cell, promoting flexibility and teamwork. In contrast, job shop manufacturing typically requires highly specialized skills for individual tasks or machines, resulting in varied labor utilization and often longer setup times due to the customized nature of production.

Quality Control and Process Consistency

Cellular manufacturing enhances quality control and process consistency by grouping similar machines into cells, enabling streamlined workflows and reducing variation through standardized processes. Job shop manufacturing, characterized by customized, low-volume production, often faces challenges in maintaining consistent quality due to diverse operations and frequent equipment changeovers. The structured layout of cellular manufacturing supports continuous quality monitoring and process improvements, leading to higher defect detection rates and consistent product output compared to the variable environment of job shops.

Implementation Challenges and Solutions

Cellular manufacturing faces implementation challenges such as high initial setup costs, complex layout design, and the need for multi-skilled workers. Job shop manufacturing struggles with scheduling inefficiencies, longer lead times, and resource allocation complexities. Solutions include adopting advanced planning software, employee cross-training, and incremental process reengineering to optimize workflow and reduce operational disruptions.

Industry Applications and Case Studies

Cellular manufacturing excels in industries like automotive and electronics, where repetitive production and component standardization improve workflow efficiency and reduce lead times. Job shop manufacturing is favored in aerospace and custom machinery sectors, supporting highly specialized, low-volume production with flexible processes tailored to unique customer requirements. Case studies reveal that automotive manufacturers adopting cellular layouts achieve up to 30% increases in productivity, while aerospace firms using job shops maintain quality and adaptability for complex, customized parts.

Work cell layout

Cellular manufacturing arranges machines into work cells based on product families to reduce movement and improve flow, while job shop manufacturing uses functional layouts grouping similar machines, leading to longer material handling and less streamlined work flow.

Routing flexibility

Cellular manufacturing offers limited routing flexibility by grouping similar processes into dedicated cells, whereas job shop manufacturing provides high routing flexibility by handling diverse and customized jobs through varied process sequences.

Batch processing

Cellular manufacturing optimizes batch processing by grouping similar machines for streamlined flow and reduced setup times, whereas job shop manufacturing handles diverse, small-batch orders with flexible, stand-alone machines leading to longer lead times.

Flow line production

Cellular manufacturing enhances flow line production by organizing workstations into cells for specific product families, improving efficiency and reducing lead times compared to the flexible but slower job shop manufacturing layout.

Machine utilization

Cellular manufacturing significantly improves machine utilization by grouping machines into cells dedicated to specific product families, reducing setup times and increasing flow efficiency compared to the variable and less predictable machine usage in job shop manufacturing.

Group technology

Cellular manufacturing uses group technology to organize similar parts into production cells, enhancing efficiency and reducing setup times compared to the flexible but less structured job shop manufacturing approach.

Production volume variability

Cellular manufacturing excels in handling moderate production volume variability through grouped workstations, while job shop manufacturing effectively manages high variability with flexible, specialized machines for custom orders.

Setup time reduction

Cellular manufacturing significantly reduces setup time by grouping similar processes and minimizing material handling compared to the longer setup times typical in job shop manufacturing with its varied, custom production workflows.

Material handling efficiency

Cellular manufacturing significantly improves material handling efficiency by minimizing transport distances and reducing motion complexity compared to the more variable and time-consuming material flow in job shop manufacturing.

Customization complexity

Cellular manufacturing streamlines moderate customization through grouped workstations oriented by similar processes, while job shop manufacturing excels in high customization complexity by handling diverse, unique product orders with flexible equipment arrangements.

Cellular manufacturing vs Job shop manufacturing Infographic

njnir.com

njnir.com