Industrial robots excel in high-speed, repetitive tasks within structured environments, delivering precision and productivity without human intervention. Collaborative robots, or cobots, are designed to work safely alongside human operators, enhancing flexibility and adaptability in dynamic production settings. This distinction highlights how industrial robots prioritize automation efficiency, while cobots emphasize human-robot interaction and shared workspace integration.

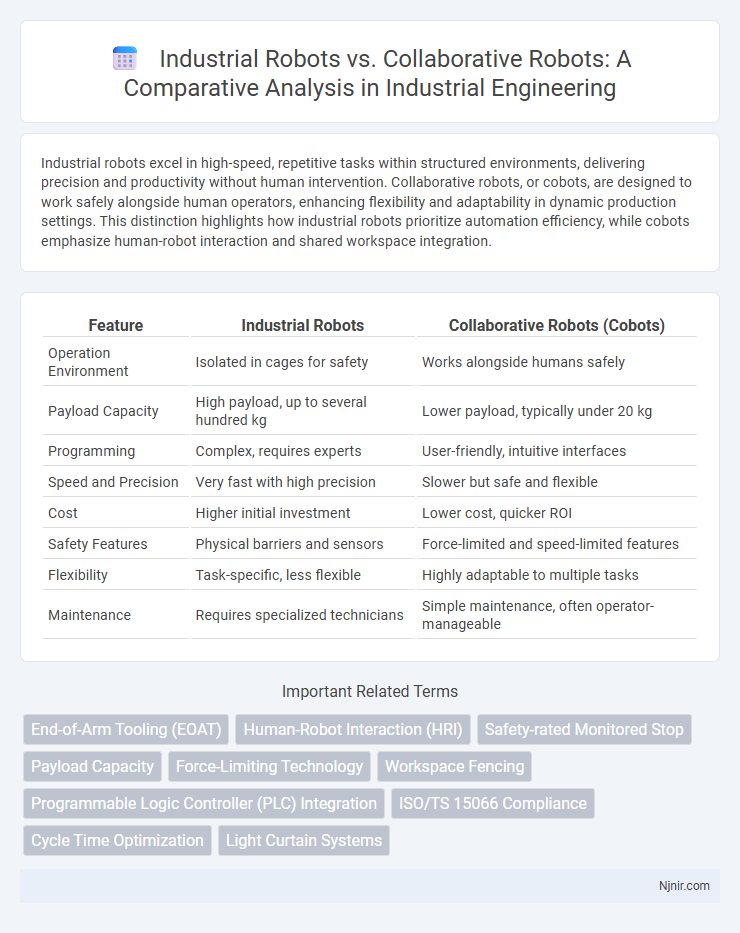

Table of Comparison

| Feature | Industrial Robots | Collaborative Robots (Cobots) |

|---|---|---|

| Operation Environment | Isolated in cages for safety | Works alongside humans safely |

| Payload Capacity | High payload, up to several hundred kg | Lower payload, typically under 20 kg |

| Programming | Complex, requires experts | User-friendly, intuitive interfaces |

| Speed and Precision | Very fast with high precision | Slower but safe and flexible |

| Cost | Higher initial investment | Lower cost, quicker ROI |

| Safety Features | Physical barriers and sensors | Force-limited and speed-limited features |

| Flexibility | Task-specific, less flexible | Highly adaptable to multiple tasks |

| Maintenance | Requires specialized technicians | Simple maintenance, often operator-manageable |

Introduction to Industrial and Collaborative Robots

Industrial robots are automated, programmable machines designed for high-speed, repetitive tasks in manufacturing environments, often operating independently within safety cages. Collaborative robots, or cobots, feature advanced sensors and artificial intelligence to work safely alongside humans, enhancing flexibility and ease of integration in diverse settings. Both types revolutionize production processes by improving precision, efficiency, and workplace safety, but cobots emphasize human-robot interaction and adaptability.

Key Differences Between Industrial and Collaborative Robots

Industrial robots excel in high-speed, repetitive tasks within controlled environments, requiring safety cages due to their force and movement speeds, whereas collaborative robots (cobots) are designed for direct human interaction with integrated safety features like force sensing and limited speed. Industrial robots feature high payload capacity and precision for manufacturing automation, while collaborative robots prioritize flexibility, ease of programming, and adaptability in mixed environments. The distinction largely lies in their deployment: industrial robots optimize productivity in isolated setups, cobots enhance agility and cooperation in shared workspaces.

Applications in Modern Manufacturing

Industrial robots excel in high-volume, repetitive tasks such as welding, painting, and assembly lines in automotive manufacturing due to their speed and precision. Collaborative robots, or cobots, are designed for close human interaction, enabling flexible applications like quality control, packaging, and small batch production in electronics and consumer goods industries. Their ability to work safely alongside operators enhances productivity in modern manufacturing environments by combining automation with manual dexterity.

Safety Features and Risk Assessments

Industrial robots are designed for high-speed, repetitive tasks in isolated environments, requiring extensive safety features such as physical barriers, emergency stop systems, and safety-rated sensors to prevent accidents. Collaborative robots (cobots) incorporate advanced safety features like force-limiting technology, speed and separation monitoring, and power and force limiting to safely work alongside humans without extensive guarding. Risk assessments for industrial robots focus on ensuring operator exclusion and machinery safeguarding, while cobot risk analysis prioritizes human-robot interaction, ergonomic impacts, and real-time hazard detection to maintain workplace safety.

Flexibility and Adaptability in Operations

Industrial robots excel in high-volume, repetitive tasks due to their rigidity and precision, offering limited flexibility for dynamic environments. Collaborative robots (cobots) provide enhanced adaptability with user-friendly programming and safe interaction alongside human workers, enabling quick reconfiguration for varied operations. This flexibility allows cobots to efficiently handle small-batch production and frequent changes in manufacturing processes, outperforming traditional industrial robots in agile settings.

Cost Considerations and ROI Analysis

Industrial robots typically require higher upfront investments ranging from $50,000 to $150,000 per unit due to complex programming and heavy-duty components, impacting overall capital expenditure. Collaborative robots (cobots) offer lower installation and maintenance costs, often priced between $20,000 and $40,000, enabling faster return on investment through flexible deployment and reduced downtime. ROI analysis reveals that cobots achieve breakeven points in 6 to 12 months, while industrial robots may take 1 to 3 years depending on application scale and production volume.

Integration with Existing Industrial Systems

Industrial robots typically require complex integration processes involving dedicated safety cages and specialized programming interfaces to operate within existing industrial systems. Collaborative robots (cobots) offer seamless integration with minimal safety barriers due to advanced sensors and flexible software platforms, enabling direct interaction with human workers on the production floor. Industry data shows that cobots reduce downtime during integration by up to 40%, enhancing operational efficiency in mixed-resource environments.

Productivity and Efficiency Comparison

Industrial robots excel in high-volume, repetitive tasks with unmatched precision and speed, significantly boosting productivity in large-scale manufacturing environments. Collaborative robots (cobots) enhance efficiency through flexible deployment and safe human-robot interaction, enabling seamless integration in varied production lines without extensive safety barriers. Productivity of industrial robots is highest in tasks requiring consistent, nonstop operation; meanwhile, cobots optimize efficiency by reducing downtime and increasing adaptability for small batch and customized production.

Workforce Impact and Human-Robot Collaboration

Industrial robots typically require safety barriers due to their high-speed, heavy-duty operations, limiting direct human interaction and potentially reducing workforce roles in hazardous tasks. Collaborative robots (cobots) are designed to work alongside humans, enhancing workforce productivity by supporting tasks that need flexibility and precision without extensive safety cages. Cobots promote human-robot collaboration by improving ergonomics, reducing repetitive strain injuries, and enabling workers to focus on higher-value activities, fostering a more integrated and adaptable workforce environment.

Future Trends in Robotic Automation

Industrial robots are advancing with enhanced AI integration and higher precision for complex manufacturing tasks, while collaborative robots (cobots) emphasize safety and flexibility to work alongside humans. The future of robotic automation points to increased interoperability between industrial robots and cobots, leveraging IoT connectivity and advanced sensors for real-time data analysis and adaptive learning. Emerging trends also include the rise of lightweight, user-friendly cobots designed for small and medium enterprises, driving widespread adoption across diverse industries.

End-of-Arm Tooling (EOAT)

End-of-Arm Tooling (EOAT) for industrial robots prioritizes high precision and heavy-duty applications, while collaborative robots' EOAT emphasizes flexibility and safety features for human-robot interaction.

Human-Robot Interaction (HRI)

Collaborative robots enhance Human-Robot Interaction (HRI) by enabling safe, intuitive, and flexible cooperation with humans, unlike traditional industrial robots that require strict safety barriers and limited direct contact.

Safety-rated Monitored Stop

Industrial robots require safety-rated monitored stop mechanisms to ensure operator protection, while collaborative robots integrate advanced monitoring systems enabling safe human-robot interaction without complete stoppage.

Payload Capacity

Industrial robots typically feature higher payload capacities ranging from 50 kg to 1000 kg, whereas collaborative robots are designed for lighter payloads generally between 3 kg and 20 kg to ensure safety in human-robot interaction environments.

Force-Limiting Technology

Force-limiting technology in collaborative robots ensures safe human-robot interaction by automatically reducing power upon contact, unlike industrial robots that rely on physical barriers and sensors for safety.

Workspace Fencing

Industrial robots require strict workspace fencing for safety, while collaborative robots operate safely alongside humans without barriers due to advanced sensors and force-limiting technology.

Programmable Logic Controller (PLC) Integration

Industrial robots require complex PLC integration for precise automation, whereas collaborative robots feature simplified PLC interfaces to enhance flexibility and ease of programming in human-robot shared environments.

ISO/TS 15066 Compliance

Collaborative robots strictly adhere to ISO/TS 15066 standards for safety and human-robot interaction, while traditional industrial robots often require additional safety measures beyond ISO/TS 15066 compliance.

Cycle Time Optimization

Industrial robots achieve faster cycle time optimization through high-speed, repetitive tasks in isolated environments while collaborative robots optimize cycle time by safely working alongside humans to enhance flexibility and reduce setup delays.

Light Curtain Systems

Light Curtain Systems in industrial robots offer robust safety barriers for high-speed automation, while collaborative robots integrate advanced light curtain sensors to enable safe human-robot interaction in shared workspaces.

Industrial robots vs Collaborative robots Infographic

njnir.com

njnir.com