Just-In-Time (JIT) manufacturing emphasizes reducing inventory waste by producing goods only as needed, streamlining production schedules and minimizing storage costs. Kanban is a visual signaling system used within JIT frameworks to control workflow, ensuring smooth material flow and preventing overproduction. Both methodologies enhance efficiency and responsiveness but Kanban provides real-time production control, making it easier to adapt to demand fluctuations.

Table of Comparison

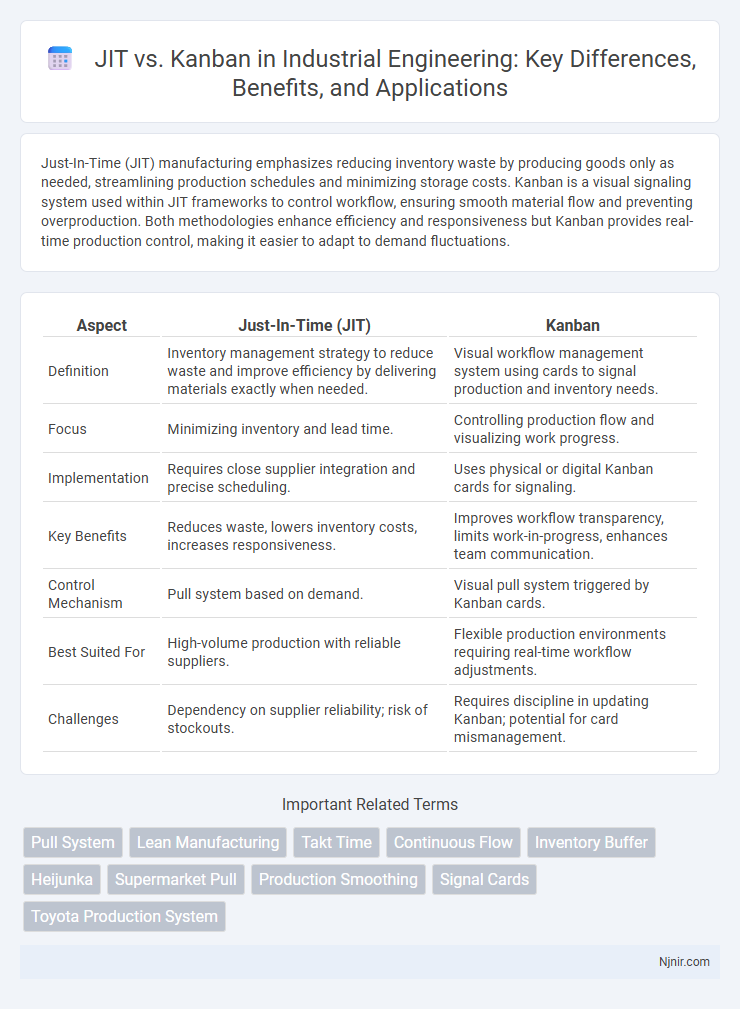

| Aspect | Just-In-Time (JIT) | Kanban |

|---|---|---|

| Definition | Inventory management strategy to reduce waste and improve efficiency by delivering materials exactly when needed. | Visual workflow management system using cards to signal production and inventory needs. |

| Focus | Minimizing inventory and lead time. | Controlling production flow and visualizing work progress. |

| Implementation | Requires close supplier integration and precise scheduling. | Uses physical or digital Kanban cards for signaling. |

| Key Benefits | Reduces waste, lowers inventory costs, increases responsiveness. | Improves workflow transparency, limits work-in-progress, enhances team communication. |

| Control Mechanism | Pull system based on demand. | Visual pull system triggered by Kanban cards. |

| Best Suited For | High-volume production with reliable suppliers. | Flexible production environments requiring real-time workflow adjustments. |

| Challenges | Dependency on supplier reliability; risk of stockouts. | Requires discipline in updating Kanban; potential for card mismanagement. |

Introduction to JIT and Kanban

Just-In-Time (JIT) is a production strategy aimed at reducing inventory costs by receiving goods only as they are needed in the manufacturing process, enhancing efficiency and minimizing waste. Kanban is a visual workflow management tool integral to JIT that uses cards or signals to trigger the movement of materials, ensuring steady production flow and inventory control. Both JIT and Kanban contribute to lean manufacturing by synchronizing supply with demand and improving process transparency.

Historical Overview: Origins of JIT and Kanban

Just-In-Time (JIT) manufacturing originated in the late 1940s at Toyota under Taiichi Ohno's leadership, aiming to minimize waste and improve production efficiency by delivering materials only as needed. Kanban, developed concurrently within Toyota, is a scheduling system that uses visual signals or cards to trigger production and inventory replenishment, effectively supporting JIT principles. Both concepts revolutionized lean manufacturing by emphasizing waste reduction, continuous flow, and responding precisely to customer demand.

Core Principles of Just-In-Time (JIT)

Just-In-Time (JIT) centers on minimizing inventory to reduce waste and improve efficiency by producing goods only as needed. Its core principles include continuous flow, pull-based production triggered by customer demand, and striving for zero defects through quality at the source. This approach contrasts with Kanban, which is a visual scheduling system aiding JIT implementation by signaling when to reorder or produce items.

Key Concepts of the Kanban System

The Kanban system emphasizes visual workflow management through cards and boards to limit work in progress, ensuring smooth task flow and reducing bottlenecks. It promotes continuous delivery by allowing teams to pull work only when they have capacity, enhancing flexibility and responsiveness. Key concepts include visualizing work, limiting WIP, managing flow, making process policies explicit, implementing feedback loops, and fostering continuous improvement.

JIT vs Kanban: Process Flow Comparison

JIT (Just-In-Time) streamlines production by delivering materials precisely when needed, minimizing inventory and reducing waste through a pull-based system triggered by demand signals. Kanban employs visual signals, such as cards or boards, to control workflow and inventory levels, facilitating smooth process flows and quick adjustments. While JIT emphasizes timing and elimination of excess inventory, Kanban focuses on visualizing work stages to optimize throughput and manage capacity effectively.

Inventory Management in JIT and Kanban

Just-In-Time (JIT) inventory management minimizes stock levels by synchronizing production schedules with demand, reducing waste and storage costs. Kanban enhances JIT by using visual signals to control workflow, ensuring materials are replenished only when consumed, which prevents overproduction. Both systems drive lean operations by promoting real-time inventory tracking and efficient resource allocation.

Benefits and Limitations of JIT

Just-In-Time (JIT) minimizes inventory costs by producing materials only as needed, enhancing cash flow and reducing waste. It improves efficiency and responsiveness but relies heavily on accurate demand forecasting and a stable supply chain, making it vulnerable to disruptions. JIT's limitations include heightened risk of stockouts and reduced buffer capacity during sudden demand spikes or supplier delays.

Advantages and Drawbacks of Kanban

Kanban offers advantages such as enhanced workflow visualization, allowing teams to identify bottlenecks and optimize task prioritization, which leads to improved efficiency and reduced lead times. The system's flexibility supports continuous delivery and limits work-in-progress, preventing overburden and facilitating smoother resource allocation. However, Kanban may struggle with scalability in large, complex projects and lacks time-boxed iterations, making it harder to enforce deadlines and measure progress consistently compared to frameworks like JIT or Scrum.

Implementation Challenges: JIT vs Kanban

Implementing Just-In-Time (JIT) systems often faces challenges such as supplier reliability issues, high demand variability, and the need for precise inventory control to avoid production delays. Kanban implementation requires careful workflow analysis, proper card system setup, and continuous communication among team members to prevent bottlenecks and ensure smooth task progression. Both methodologies demand strong organizational commitment, adaptability to process changes, and consistent monitoring to achieve optimal operational efficiency.

Choosing the Right System: Factors for Industrial Engineering

Choosing the right system between JIT (Just-In-Time) and Kanban depends on factors such as production volume, variability in demand, and inventory management needs. JIT suits industries aiming to minimize inventory and reduce waste through precise timing, while Kanban excels in visual workflow control and flexibility for continuous production. Industrial engineers must assess process complexity, supplier reliability, and lead time to determine the optimal approach for efficiency and cost-effectiveness.

Pull System

Kanban and JIT both utilize pull systems to enhance inventory efficiency by triggering production based on actual demand rather than forecasted supply.

Lean Manufacturing

JIT minimizes inventory by producing only what is needed when needed, while Kanban visually controls workflow and inventory levels to streamline Lean Manufacturing processes.

Takt Time

Takt Time is critical in JIT and Kanban systems for synchronizing production pace with customer demand to minimize waste and optimize workflow efficiency.

Continuous Flow

Kanban optimizes continuous flow by visualizing work and limiting WIP, whereas JIT focuses on reducing inventory and delivering materials exactly when needed.

Inventory Buffer

Kanban minimizes inventory buffer by using visual signals to trigger production only when needed, while JIT reduces buffer by synchronizing production precisely with demand to eliminate excess stock.

Heijunka

Heijunka smooths production by leveling workloads in Kanban systems, unlike JIT which prioritizes just-in-time inventory reduction for efficiency.

Supermarket Pull

Supermarket Pull in Kanban creates a controlled inventory buffer that triggers Just-In-Time (JIT) replenishment only when stock falls below a predefined threshold, optimizing flow and reducing waste.

Production Smoothing

Kanban minimizes production variability by visualizing work in progress, while JIT optimizes inventory levels to achieve smoother, more consistent production flows.

Signal Cards

Kanban signal cards streamline inventory replenishment by visually triggering JIT production, reducing waste and improving workflow efficiency.

Toyota Production System

The Toyota Production System utilizes Just-In-Time (JIT) to minimize inventory and Kanban to signal production needs, optimizing workflow and reducing waste.

JIT vs Kanban Infographic

njnir.com

njnir.com