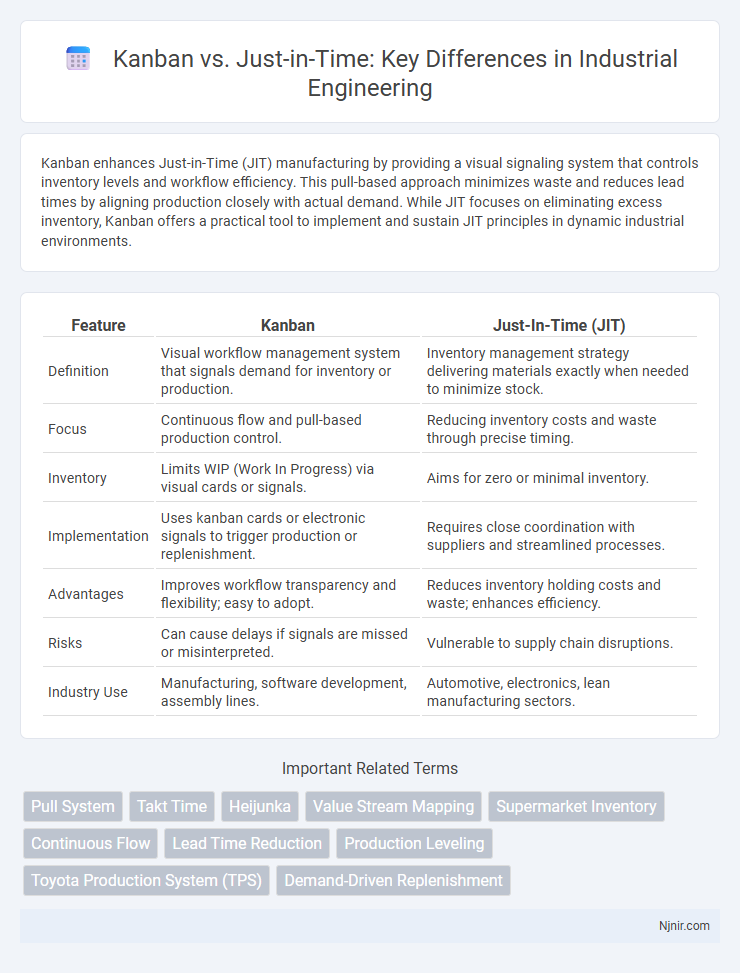

Kanban enhances Just-in-Time (JIT) manufacturing by providing a visual signaling system that controls inventory levels and workflow efficiency. This pull-based approach minimizes waste and reduces lead times by aligning production closely with actual demand. While JIT focuses on eliminating excess inventory, Kanban offers a practical tool to implement and sustain JIT principles in dynamic industrial environments.

Table of Comparison

| Feature | Kanban | Just-In-Time (JIT) |

|---|---|---|

| Definition | Visual workflow management system that signals demand for inventory or production. | Inventory management strategy delivering materials exactly when needed to minimize stock. |

| Focus | Continuous flow and pull-based production control. | Reducing inventory costs and waste through precise timing. |

| Inventory | Limits WIP (Work In Progress) via visual cards or signals. | Aims for zero or minimal inventory. |

| Implementation | Uses kanban cards or electronic signals to trigger production or replenishment. | Requires close coordination with suppliers and streamlined processes. |

| Advantages | Improves workflow transparency and flexibility; easy to adopt. | Reduces inventory holding costs and waste; enhances efficiency. |

| Risks | Can cause delays if signals are missed or misinterpreted. | Vulnerable to supply chain disruptions. |

| Industry Use | Manufacturing, software development, assembly lines. | Automotive, electronics, lean manufacturing sectors. |

Introduction to Kanban and Just-In-Time in Industrial Engineering

Kanban is a visual workflow management system designed to optimize production efficiency by signaling demand through cards or boards, enabling real-time inventory control and reducing waste. Just-In-Time (JIT) is a manufacturing methodology aimed at minimizing inventory costs by producing goods only as needed, aligning closely with lean principles to eliminate overproduction. Both Kanban and JIT enhance industrial engineering processes by synchronizing production schedules with actual demand, improving resource utilization and operational flexibility.

Historical Evolution of Kanban and JIT Systems

Kanban originated in the late 1940s as part of Toyota's manufacturing innovation, designed to optimize workflow and inventory control through visual signals. Just-In-Time (JIT) production emerged concurrently as a strategy to reduce waste by producing only what is needed, when needed, enhancing efficiency and cost-effectiveness. Both systems evolved to form the foundation of lean manufacturing, with Kanban providing a method to implement JIT principles in practical production environments.

Core Principles: Kanban vs Just-In-Time

Kanban centers on visual workflow management using cards and boards to signal task status and capacity, ensuring continuous delivery and limiting work-in-progress to enhance efficiency. Just-In-Time (JIT) emphasizes inventory reduction by producing goods only as needed, minimizing waste and aligning production closely with demand. Both systems aim to optimize flow, but Kanban focuses on process transparency and pull-based task execution, whereas JIT targets lean inventory control and precise timing.

Process Flow Comparison: Visualizing Kanban and JIT

Kanban utilizes a visual board with cards representing work items to manage workflow and limit work in progress, enabling real-time process monitoring and smooth task transitions. Just-in-Time (JIT) focuses on inventory reduction by synchronizing production schedules with demand, ensuring materials arrive exactly when needed to minimize waste. While Kanban emphasizes continuous visual management of task flow, JIT centers on precise timing and supply chain coordination to optimize production efficiency.

Inventory Management Approaches: Contrasts and Similarities

Kanban and Just-In-Time (JIT) are inventory management approaches designed to optimize production efficiency and reduce waste. Kanban uses visual signals to trigger inventory replenishment, ensuring materials are supplied only when needed, while JIT focuses on minimizing inventory levels by synchronizing production closely with demand. Both systems aim to enhance workflow and reduce excess stock, but Kanban provides a more visual and iterative control method, whereas JIT emphasizes precise timing and demand forecasting.

Production Scheduling: Kanban Cards vs JIT Triggers

Kanban uses visual Kanban cards to signal production needs and control workflow, enabling a clear and continuous scheduling process based on inventory levels and consumption rates. Just-in-Time (JIT) relies on demand-triggered production schedules that initiate manufacturing only when specific triggers, such as customer orders or inventory thresholds, are met to minimize waste and reduce lead time. Kanban's card system ensures real-time communication on shop floors, while JIT triggers emphasize precise timing to align production closely with actual demand.

Benefits and Drawbacks of Kanban and Just-In-Time

Kanban enhances workflow visibility and flexibility, reducing overproduction and inventory costs but can lead to bottlenecks if not properly managed. Just-In-Time minimizes inventory waste and storage expenses while improving cash flow, yet it is vulnerable to supply chain disruptions and demands precise demand forecasting. Both systems boost efficiency but require careful implementation to balance responsiveness and risk.

Implementation Challenges in Industrial Settings

Implementing Kanban in industrial settings often faces challenges such as resistance to change, difficulty in maintaining real-time inventory visibility, and the complexity of integrating with existing production schedules. Just-in-time (JIT) systems encounter obstacles including supplier reliability issues, demand variability, and the need for precise coordination across the supply chain. Both methodologies require robust communication channels and adaptive process control to overcome operational disruptions and ensure seamless workflow.

Real-World Case Studies: Kanban and JIT Applications

Toyota's implementation of Kanban significantly enhanced its Just-in-Time (JIT) manufacturing system by visually controlling inventory levels and workflow, reducing waste and improving efficiency. Dell's use of JIT principles in its supply chain allowed rapid assembly of customized computers while Kanban boards helped monitor order status and manage inventory dynamically. Both methodologies have demonstrated measurable improvements in lead time reduction, inventory turnover, and operational flexibility across diverse industries such as automotive, electronics, and retail.

Choosing the Right System: Factors for Industrial Engineers

Industrial engineers must evaluate production demand variability, inventory costs, and lead times when choosing between Kanban and Just-In-Time systems. Kanban excels in environments with stable demand and limited work-in-progress inventory control, while Just-In-Time is ideal for reducing waste by synchronizing production closely with customer orders. Considering factors such as supplier reliability, production complexity, and responsiveness helps optimize supply chain efficiency and operational performance.

Pull System

Kanban and Just-In-Time (JIT) both utilize a pull system to optimize inventory management by signaling production only when demand exists, reducing waste and improving efficiency.

Takt Time

Kanban systems synchronize workflow by visualizing tasks, while Just-in-Time production uses Takt Time to pace manufacturing processes precisely with customer demand to minimize waste.

Heijunka

Heijunka, a key aspect of Just-In-Time manufacturing, smooths production by leveling workload to reduce waste, contrasting with Kanban's visual signaling system for inventory control.

Value Stream Mapping

Value Stream Mapping in Kanban identifies workflow bottlenecks and optimizes WIP limits, while Just-In-Time focuses on minimizing inventory by synchronizing production with demand for efficient value delivery.

Supermarket Inventory

Kanban optimizes supermarket inventory by signaling precise reorder quantities to maintain just-in-time stock levels, reducing waste and preventing overstocking.

Continuous Flow

Kanban enhances continuous flow in production by visualizing work stages and limiting work in progress, whereas Just-In-Time emphasizes inventory reduction and synchronized supply with demand.

Lead Time Reduction

Kanban improves lead time reduction by visually managing work-in-progress and triggering replenishment only when needed, while Just-In-Time minimizes lead time by synchronizing production precisely with demand to eliminate excess inventory and delays.

Production Leveling

Kanban enhances production leveling by visually controlling work-in-progress and synchronizing workflow, while Just-In-Time minimizes inventory by producing exactly what is needed when needed to achieve smooth, balanced production.

Toyota Production System (TPS)

Kanban is a visual scheduling system integral to the Toyota Production System (TPS) that enables just-in-time (JIT) production by signaling precise inventory replenishment to minimize waste and enhance efficiency.

Demand-Driven Replenishment

Kanban enables Demand-Driven Replenishment by signaling exact inventory needs to minimize waste, whereas Just-In-Time emphasizes synchronized production schedules to reduce lead times and inventory levels.

kanban vs just-in-time Infographic

njnir.com

njnir.com