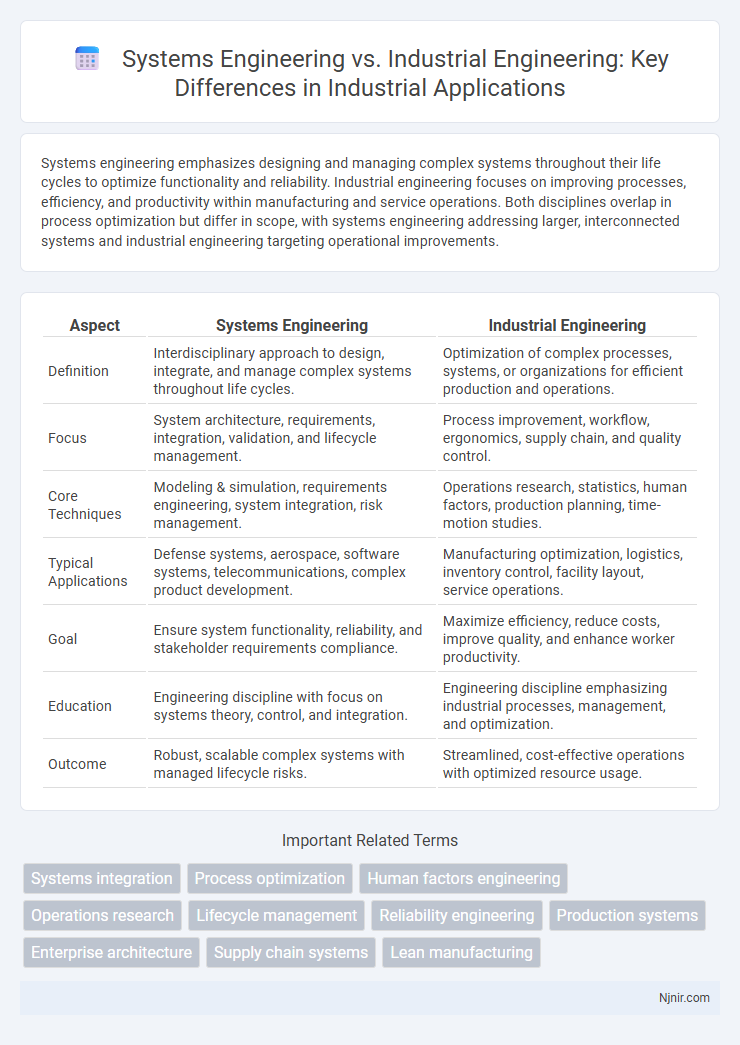

Systems engineering emphasizes designing and managing complex systems throughout their life cycles to optimize functionality and reliability. Industrial engineering focuses on improving processes, efficiency, and productivity within manufacturing and service operations. Both disciplines overlap in process optimization but differ in scope, with systems engineering addressing larger, interconnected systems and industrial engineering targeting operational improvements.

Table of Comparison

| Aspect | Systems Engineering | Industrial Engineering |

|---|---|---|

| Definition | Interdisciplinary approach to design, integrate, and manage complex systems throughout life cycles. | Optimization of complex processes, systems, or organizations for efficient production and operations. |

| Focus | System architecture, requirements, integration, validation, and lifecycle management. | Process improvement, workflow, ergonomics, supply chain, and quality control. |

| Core Techniques | Modeling & simulation, requirements engineering, system integration, risk management. | Operations research, statistics, human factors, production planning, time-motion studies. |

| Typical Applications | Defense systems, aerospace, software systems, telecommunications, complex product development. | Manufacturing optimization, logistics, inventory control, facility layout, service operations. |

| Goal | Ensure system functionality, reliability, and stakeholder requirements compliance. | Maximize efficiency, reduce costs, improve quality, and enhance worker productivity. |

| Education | Engineering discipline with focus on systems theory, control, and integration. | Engineering discipline emphasizing industrial processes, management, and optimization. |

| Outcome | Robust, scalable complex systems with managed lifecycle risks. | Streamlined, cost-effective operations with optimized resource usage. |

Overview of Systems Engineering and Industrial Engineering

Systems engineering focuses on designing, integrating, and managing complex systems throughout their life cycles, emphasizing interdisciplinary collaboration and optimization of system performance. Industrial engineering aims to improve processes, systems, and organizations by applying principles of efficiency, productivity, and quality to manufacturing, service, and supply chain operations. Both fields utilize analytical methods but differ in scope, with systems engineering addressing whole system integration and industrial engineering concentrating on process and resource optimization.

Historical Development of Both Disciplines

Systems engineering emerged during the mid-20th century primarily to address the complexities of aerospace and defense projects, emphasizing interdisciplinary integration and lifecycle management of large-scale systems. Industrial engineering has roots dating back to the early 20th century, evolving from manufacturing and operations management to optimize efficiency, productivity, and ergonomics in industrial settings. Both disciplines have historically developed in response to technological advancements and the increasing need for structured problem-solving methodologies in complex environments.

Core Principles and Philosophies

Systems engineering emphasizes an interdisciplinary approach to design, integration, and management of complex systems throughout their life cycles, focusing on requirements analysis, system architecture, and verification. Industrial engineering centers on optimizing processes, systems, and organizations by applying principles of efficiency, quality control, and human factors to improve productivity and reduce waste. Both fields prioritize problem-solving and systems thinking but differ in scope, with systems engineering targeting large-scale, multifaceted systems and industrial engineering concentrating on operational and process improvements.

Key Roles and Responsibilities

Systems engineering emphasizes designing, integrating, and managing complex systems throughout their life cycles, focusing on requirements analysis, system architecture, and validation to ensure operational effectiveness. Industrial engineering concentrates on optimizing processes, supply chains, and production systems to improve efficiency, reduce waste, and enhance quality through methods such as workflow analysis, ergonomics, and resource management. Both disciplines require strong problem-solving skills but differ fundamentally in scope: systems engineers handle multi-disciplinary system integration, while industrial engineers focus on process optimization within organizations.

Methodologies and Tools Used

Systems engineering primarily utilizes methodologies such as requirements analysis, systems architecture design, and verification and validation processes, supported by tools like SysML modeling software, MATLAB, and simulation platforms. Industrial engineering emphasizes process optimization, workflow analysis, and quality control techniques, leveraging tools including time-motion studies, statistical process control (SPC) software, and discrete event simulation. Both disciplines incorporate data-driven decision-making methods but apply distinct frameworks tailored to system complexity versus operational efficiency.

Industry Applications and Sectors

Systems engineering applies primarily to complex, interdisciplinary projects in aerospace, defense, telecommunications, and software development, emphasizing system integration, lifecycle management, and reliability. Industrial engineering targets manufacturing, logistics, healthcare, and service industries, focusing on optimizing processes, improving efficiency, and reducing waste. Both fields contribute to industry sectors by enhancing operational performance but differ in scope and methodological approaches tailored to their respective applications.

Skills and Educational Requirements

Systems engineering requires strong skills in systems thinking, process optimization, and complex problem-solving, with an educational background typically including a bachelor's or master's degree in systems engineering, electrical engineering, or computer science. Industrial engineering emphasizes skills in operations research, quality control, and supply chain management, with degrees often in industrial engineering, manufacturing engineering, or business analytics. Both fields demand proficiency in mathematics, data analysis, and project management, but systems engineering leans more towards technical systems integration, while industrial engineering focuses on improving efficiency and productivity in manufacturing and services.

Collaboration and Interdisciplinary Approaches

Systems engineering integrates multidisciplinary teams to design, analyze, and optimize complex systems, emphasizing collaboration across engineering, management, and user domains. Industrial engineering employs interdisciplinary collaboration by combining principles from operations research, human factors, and supply chain management to improve efficiency and productivity. Both fields rely heavily on cooperative approaches, but systems engineering often orchestrates broader systemic integration while industrial engineering focuses on optimizing operational processes within organizations.

Emerging Trends and Future Outlook

Systems engineering increasingly integrates artificial intelligence, digital twins, and cyber-physical systems to enhance complex system design and lifecycle management. Industrial engineering focuses on smart manufacturing, IoT-driven process optimization, and sustainable supply chain innovations to improve operational efficiency. Both fields converge on leveraging data analytics and automation to address evolving technological challenges and drive Industry 4.0 advancements.

Choosing Between Systems Engineering and Industrial Engineering

Choosing between systems engineering and industrial engineering depends on project scope and objectives; systems engineering emphasizes designing and managing complex system integrations, while industrial engineering focuses on optimizing processes, efficiency, and resource management in manufacturing and service industries. Systems engineering professionals typically work on large-scale technical projects involving system lifecycle management, whereas industrial engineers prioritize workflow improvement, cost reduction, and quality control. Understanding industry demands and career goals helps determine whether the multidisciplinary, technical systems approach or the process-oriented, efficiency-driven industrial approach aligns best with individual expertise and business needs.

Systems integration

Systems engineering prioritizes holistic systems integration to optimize complex, multidisciplinary projects, while industrial engineering focuses on improving efficiency and productivity within individual processes and operations.

Process optimization

Systems engineering optimizes complex system processes by integrating interdisciplinary methods, while industrial engineering focuses on enhancing manufacturing and operational workflows for efficiency and productivity.

Human factors engineering

Human factors engineering in systems engineering emphasizes optimizing human-system interactions for overall system performance, while in industrial engineering, it focuses on improving workplace design and human productivity within manufacturing and service processes.

Operations research

Operations research in systems engineering emphasizes optimizing complex system designs and integration, while in industrial engineering it focuses on improving manufacturing processes and operational efficiency.

Lifecycle management

Systems engineering optimizes product lifecycle management by integrating multidisciplinary processes, while industrial engineering enhances lifecycle efficiency through process improvement and resource optimization.

Reliability engineering

Reliability engineering integrates principles from both systems engineering and industrial engineering to enhance the lifespan, performance, and dependability of complex systems through risk analysis, maintenance strategies, and failure prevention techniques.

Production systems

Systems engineering integrates complex production system design and optimization through interdisciplinary approaches, while industrial engineering emphasizes efficiency and process improvement within production systems using techniques like workflow analysis and resource management.

Enterprise architecture

Enterprise architecture integrates systems engineering principles to design and optimize complex organizational processes, while industrial engineering focuses on improving operational efficiency and resource management within those systems.

Supply chain systems

Systems engineering optimizes supply chain systems by integrating complex processes and technologies for improved efficiency, while industrial engineering focuses on streamlining supply chain operations through workflow analysis and resource allocation.

Lean manufacturing

Lean manufacturing integrates industrial engineering principles to optimize production efficiency, while systems engineering focuses on designing and managing complex systems across the entire product lifecycle.

Systems engineering vs Industrial engineering Infographic

njnir.com

njnir.com