Cellular manufacturing enhances efficiency by grouping machines into cells that produce similar products, reducing setup times and inventory levels. Mass production relies on high-volume, standardized processes designed for economies of scale but often lacks flexibility and can lead to higher waste. Adopting cellular manufacturing can improve responsiveness to customer demands and support lean production principles in industrial engineering.

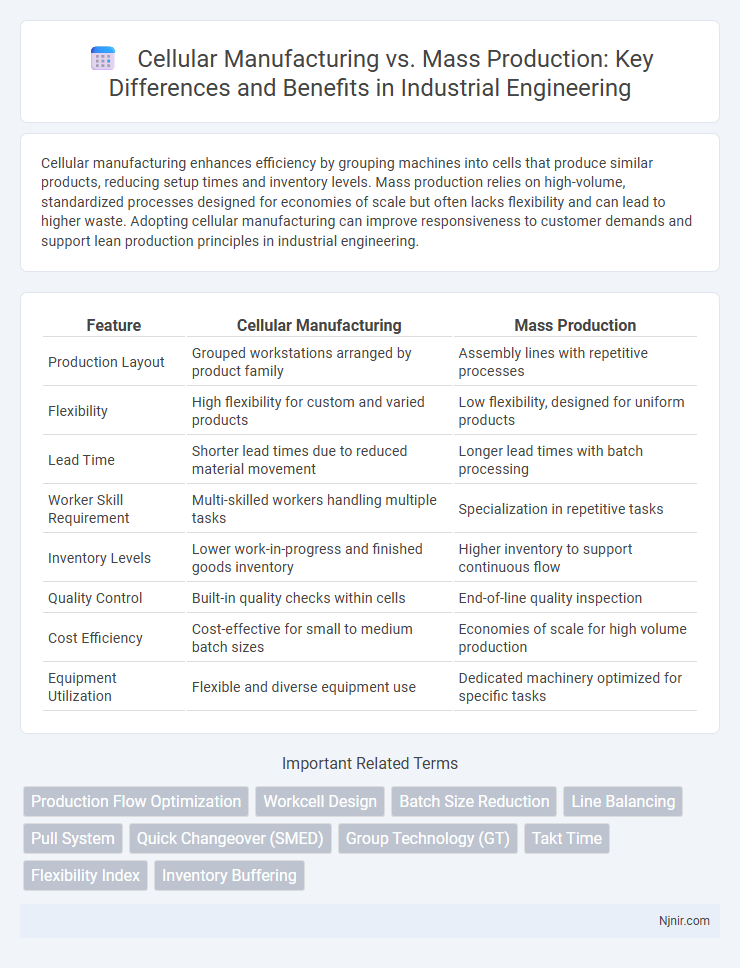

Table of Comparison

| Feature | Cellular Manufacturing | Mass Production |

|---|---|---|

| Production Layout | Grouped workstations arranged by product family | Assembly lines with repetitive processes |

| Flexibility | High flexibility for custom and varied products | Low flexibility, designed for uniform products |

| Lead Time | Shorter lead times due to reduced material movement | Longer lead times with batch processing |

| Worker Skill Requirement | Multi-skilled workers handling multiple tasks | Specialization in repetitive tasks |

| Inventory Levels | Lower work-in-progress and finished goods inventory | Higher inventory to support continuous flow |

| Quality Control | Built-in quality checks within cells | End-of-line quality inspection |

| Cost Efficiency | Cost-effective for small to medium batch sizes | Economies of scale for high volume production |

| Equipment Utilization | Flexible and diverse equipment use | Dedicated machinery optimized for specific tasks |

Introduction to Cellular Manufacturing and Mass Production

Cellular manufacturing organizes workstations into small, self-contained units called cells, each responsible for producing a family of similar products, optimizing workflow and minimizing waste. Mass production relies on high-volume, standardized processes with specialized equipment designed for continuous, large-scale output of identical products. Cellular manufacturing enhances flexibility and responsiveness, while mass production maximizes efficiency and economies of scale through repetitive, assembly-line techniques.

Key Principles of Cellular Manufacturing

Cellular manufacturing organizes workstations into small, self-contained units called cells, each dedicated to producing a set of similar products, which enhances workflow efficiency and reduces lead times. Key principles include the grouping of machines and workers based on the sequence of operations, minimizing material movement, and promoting a continuous flow that supports just-in-time production. This contrasts with mass production's focus on high-volume, standardized output through assembly line processes with less flexibility and higher inventory levels.

Core Concepts of Mass Production

Mass production centers on the large-scale, standardized manufacturing of homogeneous products using assembly lines to maximize output efficiency and reduce per-unit costs. It relies on high-volume workflows, specialized machinery, and labor division to achieve economies of scale and consistent product quality. Key principles include repetitive processes, mechanization, and minimal product variation to optimize speed and cost-effectiveness.

Efficiency Comparison: Cellular vs Mass Production

Cellular manufacturing significantly improves efficiency by grouping different machines into cells that focus on specific product families, reducing material handling and setup times compared to mass production's large, continuous runs. This method minimizes work-in-progress inventory and enhances flexibility, enabling quicker response to demand changes while maintaining high throughput. Mass production excels in economies of scale for high-volume, standardized products but often suffers from longer lead times and increased waste due to less adaptable workflows.

Flexibility and Customization Capabilities

Cellular manufacturing enhances flexibility by organizing workstations into cells dedicated to producing a family of similar products, allowing rapid adjustments to design changes and small batch variations. In contrast, mass production emphasizes high-volume output with standardized processes, limiting customization and reducing responsiveness to product variations. This approach prioritizes efficiency over flexibility, making cellular manufacturing superior for environments requiring frequent customization and agile production shifts.

Quality Control in Both Manufacturing Systems

Cellular manufacturing improves quality control by organizing workstations into cells that focus on specific product families, enabling faster detection and correction of defects and reducing variability. Mass production employs standardized processes and rigorous inspection protocols at various stages to maintain consistent quality across high volumes, but can struggle with identifying issues promptly due to the linear workflow. The integration of real-time monitoring and worker autonomy in cellular manufacturing creates a more responsive quality control environment compared to the often rigid and scale-dependent quality assurance measures in mass production.

Workforce Roles and Skill Requirements

Cellular manufacturing requires a versatile workforce skilled in multiple tasks, fostering teamwork and problem-solving within small, self-managed cells to increase flexibility and reduce downtime. Mass production relies on specialized roles with repetitive tasks, emphasizing efficiency and consistency through worker specialization and minimal cross-training. The skill requirements in cellular manufacturing prioritize adaptability and multi-functionality, while mass production focuses on operational precision and task repetition.

Implementation Challenges and Risks

Cellular manufacturing faces implementation challenges such as high initial capital investment, complex workforce training requirements, and logistical difficulties in redesigning workflows to achieve cell-based production. Mass production presents risks including inflexibility in adapting to product variation, increased waste during demand fluctuations, and vulnerability to supply chain disruptions due to its reliance on standardized processes. Both systems require careful risk management strategies to address scalability issues and maintain operational efficiency.

Cost Implications and Scalability

Cellular manufacturing reduces work-in-progress inventory and setup times, leading to lower operational costs compared to mass production, which often incurs higher expenses due to large batch setups and inventory holding. Scalability in cellular manufacturing is flexible, allowing easier adjustment to varying demand without significant cost increases, whereas mass production is optimized for high volumes but faces cost inefficiencies when scaling down or adjusting product variety. The cost implications favor cellular manufacturing for customized, low-to-medium volume production, while mass production remains cost-effective for standardized, high-volume output.

Future Trends in Manufacturing Systems

Cellular manufacturing is evolving with the integration of Industry 4.0 technologies such as IoT, AI, and automation, enabling flexible, customized production with reduced lead times and waste. Mass production continues to benefit from advanced robotics and data analytics, optimizing efficiency and scalability for high-volume output. Future manufacturing systems increasingly blend these approaches, leveraging smart cells within mass production lines to balance customization and productivity.

Production Flow Optimization

Cellular manufacturing optimizes production flow by grouping related processes into cells for streamlined efficiency, unlike mass production which relies on continuous, linear assembly lines.

Workcell Design

Cellular manufacturing enhances workcell design by organizing machines and operators into compact, flexible units tailored for specific product families, contrasting the linear, high-volume workstation layout of traditional mass production.

Batch Size Reduction

Cellular manufacturing reduces batch size by organizing workstations into efficient cells that streamline production flow, contrasting with mass production's large batch sizes that prioritize volume over flexibility.

Line Balancing

Cellular manufacturing enhances line balancing by grouping diverse machines into cells that streamline workflow and reduce bottlenecks, whereas mass production relies on sequential, specialized stations often leading to imbalanced workloads and increased idle time.

Pull System

Cellular manufacturing enhances efficiency by implementing a pull system that minimizes inventory and responds directly to customer demand, unlike mass production which relies on push systems and large batch processing.

Quick Changeover (SMED)

Cellular manufacturing significantly reduces changeover time through Single-Minute Exchange of Dies (SMED), enabling faster transitions and higher flexibility compared to traditional mass production methods.

Group Technology (GT)

Cellular manufacturing leverages Group Technology (GT) to organize similar parts into families for streamlined production, enhancing flexibility and reducing lead times compared to traditional mass production methods.

Takt Time

Cellular manufacturing reduces takt time variability by organizing workstations to complete products synchronously, whereas mass production often experiences longer, less flexible takt times due to batch processing.

Flexibility Index

Cellular manufacturing exhibits a higher Flexibility Index than mass production by enabling quicker adaptation to product variety and demand changes through modular work cells.

Inventory Buffering

Cellular manufacturing minimizes inventory buffering by organizing workstations into compact cells that enable just-in-time production, while mass production relies heavily on large inventory buffers to maintain continuous flow across separate stages.

Cellular Manufacturing vs Mass Production Infographic

njnir.com

njnir.com