Digital twin technology creates a dynamic, real-time virtual replica of physical industrial systems, enabling continuous monitoring and predictive maintenance. Simulation modeling offers a static or scenario-based exploration of processes, useful for designing and testing without real-time data integration. Industrial engineers leverage digital twins for enhanced operational insights, while simulation models support strategic planning and process optimization.

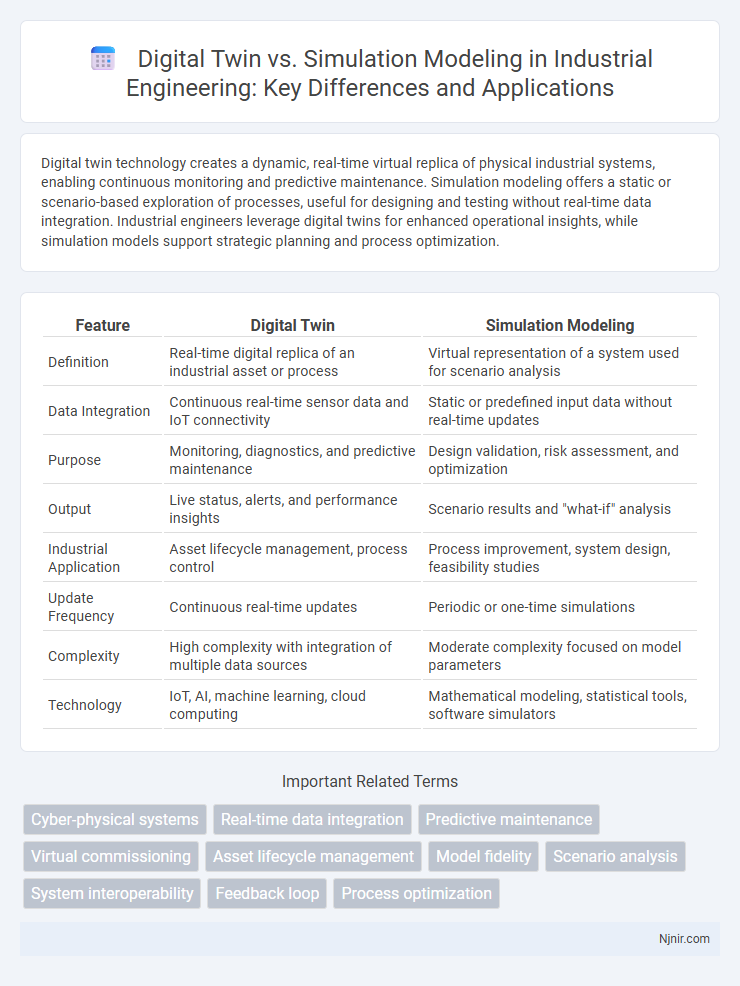

Table of Comparison

| Feature | Digital Twin | Simulation Modeling |

|---|---|---|

| Definition | Real-time digital replica of an industrial asset or process | Virtual representation of a system used for scenario analysis |

| Data Integration | Continuous real-time sensor data and IoT connectivity | Static or predefined input data without real-time updates |

| Purpose | Monitoring, diagnostics, and predictive maintenance | Design validation, risk assessment, and optimization |

| Output | Live status, alerts, and performance insights | Scenario results and "what-if" analysis |

| Industrial Application | Asset lifecycle management, process control | Process improvement, system design, feasibility studies |

| Update Frequency | Continuous real-time updates | Periodic or one-time simulations |

| Complexity | High complexity with integration of multiple data sources | Moderate complexity focused on model parameters |

| Technology | IoT, AI, machine learning, cloud computing | Mathematical modeling, statistical tools, software simulators |

Overview: Defining Digital Twin and Simulation Modeling

Digital twin technology creates a real-time digital replica of physical assets, processes, or systems, enabling continuous monitoring and dynamic feedback. Simulation modeling builds virtual scenarios to analyze system behavior under various hypothetical conditions without real-time data integration. Both approaches facilitate decision-making, but digital twins offer a live data connection, while simulation models rely on predefined inputs and assumptions.

Core Technologies: Digital Twin vs Simulation Modeling

Digital Twin technology integrates real-time data from IoT sensors and AI analytics to create dynamic, continuously updated virtual replicas of physical assets, enabling predictive maintenance and operational optimization. Simulation modeling relies on mathematical algorithms and scenario-based data inputs to replicate processes or systems, focusing primarily on hypothetical testing and system behavior analysis without real-time updates. Combining digital twin's real-time data synchronization with simulation modeling's scenario analysis enhances decision-making accuracy across industries like manufacturing, healthcare, and smart cities.

Main Applications in Industrial Engineering

Digital twin technology enables real-time monitoring and predictive maintenance by creating a dynamic replica of industrial systems, enhancing asset management and operational efficiency. Simulation modeling primarily supports process optimization and design validation by analyzing hypothetical scenarios and workflow performance without physical intervention. Both approaches are integral in manufacturing, with digital twins offering continuous system insights and simulation models providing detailed feasibility studies and risk assessments.

Real-Time Data Integration and Connectivity

Digital twin technology integrates real-time data streams from IoT sensors, enabling continuous monitoring and dynamic updates of physical assets or processes, whereas traditional simulation modeling relies on static or pre-defined datasets without real-time feedback. This connectivity in digital twins facilitates predictive maintenance, performance optimization, and scenario testing under live conditions, providing superior situational awareness compared to simulation models. Real-time data integration transforms digital twins into actionable decision-making tools that adapt instantly to changes in the physical environment.

Accuracy and Fidelity of Digital Representations

Digital twins provide real-time, dynamic digital representations of physical assets by integrating live sensor data, which greatly enhances accuracy and fidelity compared to traditional simulation modeling. Simulation models often rely on static or theoretical data inputs that may not capture the complexities or changing conditions of the physical environment, leading to less precise projections. The continuous feedback loop in digital twins allows for ongoing calibration and refinement, ensuring the digital model closely mirrors actual performance and behavior over time.

Use Cases: Predictive Maintenance and Process Optimization

Digital twin technology enables real-time monitoring and predictive maintenance by creating a dynamic digital replica of physical assets, capturing live sensor data to forecast equipment failures and schedule timely interventions. Simulation modeling supports process optimization through hypothesis testing and scenario analysis, allowing businesses to evaluate potential improvements in workflows without disrupting operations. Combining digital twins with simulation enhances decision-making accuracy by integrating current system states with predictive analytics for optimized maintenance and operational efficiency.

Scalability and Complexity in Implementation

Digital twin technology offers enhanced scalability by continuously integrating real-time data from physical assets, enabling dynamic and adaptive system representations, while simulation modeling typically relies on static data and predefined scenarios that limit scalability. Complex implementation of digital twins involves extensive sensor integration, IoT infrastructure, and data analytics platforms to maintain real-time synchronization, making it more resource-intensive compared to simulation models that primarily focus on algorithmic logic and scenario analysis. The evolving nature of digital twins supports iterative complexity management and broader system interactions, whereas simulation modeling remains constrained by initial assumptions and lacks real-time responsiveness.

Decision-Making Support: Insights and Analytics

Digital twins provide real-time data integration and continuous monitoring, enabling dynamic decision-making support with up-to-date insights and predictive analytics. Simulation modeling offers scenario testing and virtual experimentation based on predefined models, useful for evaluating potential outcomes without real-time data dependency. Combining digital twins and simulation modeling enhances decision-making by merging real-world data accuracy with flexible scenario analysis.

Challenges and Limitations in Industrial Context

Digital twin technology often faces challenges related to the integration of real-time data from diverse industrial IoT devices, resulting in potential synchronization and scalability issues. Simulation modeling, while useful for hypothetical scenario analysis, struggles with accurately representing complex dynamic interactions and requires extensive computational resources for high-fidelity results. Both approaches encounter limitations in handling massive datasets and ensuring cybersecurity within industrial environments.

Future Trends: Convergence and Evolution in Industry

Digital twin technology is evolving to integrate real-time IoT data, enabling continuous feedback loops that enhance predictive maintenance and operational optimization beyond traditional simulation modeling's static scenarios. Future trends emphasize the convergence of digital twins with AI-driven analytics and advanced simulation techniques, creating dynamic, adaptive models that reflect real-world conditions with high fidelity. Industries such as manufacturing, aerospace, and smart cities will leverage this evolution for improved decision-making, reduced downtime, and accelerated innovation cycles.

Cyber-physical systems

Digital twins provide real-time, dynamic representation of cyber-physical systems by integrating sensor data and simulation models, whereas simulation modeling primarily offers static, scenario-based analysis without continuous system synchronization.

Real-time data integration

Digital twins leverage real-time data integration for continuous system replication and dynamic optimization, while simulation modeling primarily relies on static or periodic data snapshots for scenario analysis.

Predictive maintenance

Digital twins provide real-time data integration and continuous system updates for predictive maintenance, while simulation modeling relies on static scenarios lacking dynamic operational feedback.

Virtual commissioning

Digital twin technology provides real-time data integration and dynamic system representation, enabling more accurate and efficient virtual commissioning compared to traditional simulation modeling methods.

Asset lifecycle management

Digital twin technology offers real-time, data-driven asset lifecycle management by continuously mirroring physical asset conditions, whereas simulation modeling provides predictive analysis based on static or historical data.

Model fidelity

Digital twin technology offers higher model fidelity by integrating real-time data and dynamic updates, unlike traditional simulation modeling which relies on static, pre-defined parameters.

Scenario analysis

Digital twins enable real-time scenario analysis by integrating live data for dynamic system behavior prediction, whereas simulation modeling uses static, predefined parameters for hypothetical scenario testing.

System interoperability

Digital twins enable real-time system interoperability by continuously syncing physical assets with virtual models, whereas simulation modeling typically operates in isolated, static environments without dynamic data exchange.

Feedback loop

Digital twins continuously integrate real-time sensor data through a dynamic feedback loop, enabling accurate system replication and predictive analysis, whereas traditional simulation modeling typically operates on static or predefined parameters without continuous real-time updates.

Process optimization

Digital twins enable real-time process optimization through continuous data integration, while simulation modeling offers scenario-based analysis without live system feedback.

Digital twin vs Simulation modeling Infographic

njnir.com

njnir.com