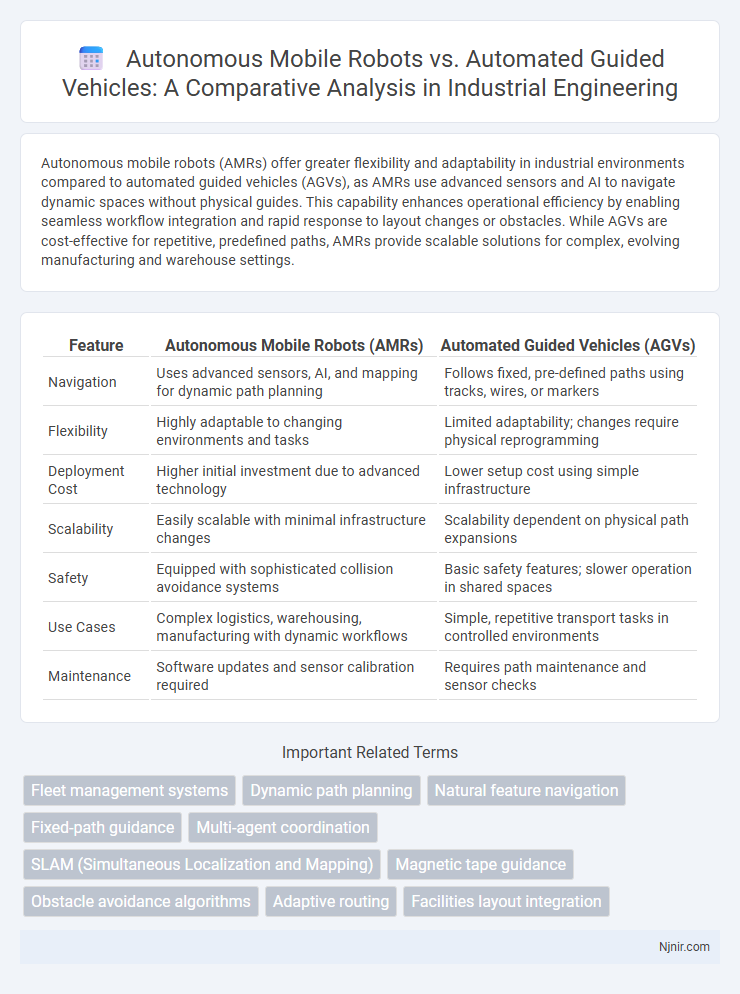

Autonomous mobile robots (AMRs) offer greater flexibility and adaptability in industrial environments compared to automated guided vehicles (AGVs), as AMRs use advanced sensors and AI to navigate dynamic spaces without physical guides. This capability enhances operational efficiency by enabling seamless workflow integration and rapid response to layout changes or obstacles. While AGVs are cost-effective for repetitive, predefined paths, AMRs provide scalable solutions for complex, evolving manufacturing and warehouse settings.

Table of Comparison

| Feature | Autonomous Mobile Robots (AMRs) | Automated Guided Vehicles (AGVs) |

|---|---|---|

| Navigation | Uses advanced sensors, AI, and mapping for dynamic path planning | Follows fixed, pre-defined paths using tracks, wires, or markers |

| Flexibility | Highly adaptable to changing environments and tasks | Limited adaptability; changes require physical reprogramming |

| Deployment Cost | Higher initial investment due to advanced technology | Lower setup cost using simple infrastructure |

| Scalability | Easily scalable with minimal infrastructure changes | Scalability dependent on physical path expansions |

| Safety | Equipped with sophisticated collision avoidance systems | Basic safety features; slower operation in shared spaces |

| Use Cases | Complex logistics, warehousing, manufacturing with dynamic workflows | Simple, repetitive transport tasks in controlled environments |

| Maintenance | Software updates and sensor calibration required | Requires path maintenance and sensor checks |

Introduction to Mobile Robotics in Industrial Engineering

Autonomous mobile robots (AMRs) and automated guided vehicles (AGVs) are pivotal in industrial engineering for optimizing material handling and production workflows. AMRs utilize advanced sensors and AI for dynamic path planning and obstacle avoidance, enabling flexible navigation in complex environments, while AGVs rely on fixed routes and predefined guidance systems such as magnetic strips or wires. Understanding the distinctions between AMRs and AGVs is essential for implementing efficient mobile robotics solutions that enhance manufacturing efficiency and adaptability.

Defining Autonomous Mobile Robots (AMRs)

Autonomous Mobile Robots (AMRs) are intelligent machines equipped with advanced sensors, cameras, and AI-driven navigation systems that enable them to operate independently within dynamic environments without relying on fixed paths. Unlike Automated Guided Vehicles (AGVs), which follow predetermined tracks or wires, AMRs use real-time mapping and obstacle avoidance to optimize routes and adapt to changes on the fly. These capabilities make AMRs highly flexible for tasks such as material handling, warehouse automation, and logistics in complex or evolving industrial settings.

Understanding Automated Guided Vehicles (AGVs)

Automated Guided Vehicles (AGVs) are mobile robots designed to transport materials within manufacturing facilities, warehouses, and distribution centers using pre-defined paths guided by magnets, lasers, or wires embedded in floors. Unlike Autonomous Mobile Robots (AMRs), which use advanced sensors and AI for dynamic navigation and decision-making, AGVs rely on fixed routes and external guidance systems, limiting their flexibility but ensuring predictable and repeatable operations. AGVs are widely used for tasks such as pallet transport, assembly line feeding, and inventory movement, offering high reliability in structured environments where route optimization is less critical.

Key Technological Differences: AMRs vs AGVs

Autonomous Mobile Robots (AMRs) utilize advanced sensors, machine learning, and onboard processing to navigate dynamically and adapt to changing environments without fixed paths. Automated Guided Vehicles (AGVs) rely on pre-defined tracks, magnetic tape, or wires for navigation, limiting flexibility but ensuring predictable routes for material transport. AMRs offer superior autonomy and obstacle avoidance, whereas AGVs provide reliability in repetitive, structured workflows.

Navigation and Sensing Capabilities

Autonomous mobile robots (AMRs) employ advanced sensor fusion techniques including LiDAR, cameras, and ultrasonic sensors to create dynamic maps and adapt their navigation paths in real-time, enabling flexible route planning in complex environments. Automated guided vehicles (AGVs) rely primarily on fixed paths guided by magnetic strips, lasers, or wire tracks, limiting their navigation to pre-defined routes with minimal environmental sensing. The superior sensing capabilities of AMRs allow for obstacle detection and avoidance, supporting autonomous decision-making beyond the static guidance systems of AGVs.

Flexibility and Adaptability in Industrial Environments

Autonomous mobile robots (AMRs) offer superior flexibility and adaptability in industrial environments compared to automated guided vehicles (AGVs) due to their advanced sensors and AI-driven navigation systems, enabling dynamic path planning and obstacle avoidance. Unlike AGVs, which rely on fixed tracks or magnetic tape for guidance, AMRs can easily adjust to layout changes and interact seamlessly with human workers and other machines. This capability significantly enhances operational efficiency by supporting complex tasks and varied workflows without requiring extensive infrastructure modifications.

Implementation Costs and Return on Investment

Autonomous mobile robots (AMRs) typically involve higher initial implementation costs due to advanced sensor technology and AI-driven navigation systems compared to automated guided vehicles (AGVs), which rely on fixed paths and simpler infrastructure. Despite the greater upfront investment, AMRs often deliver a faster return on investment (ROI) by enhancing operational flexibility, reducing downtime, and enabling scalable deployment across varied environments. AGVs may provide lower initial costs but can incur additional expenses over time due to limited adaptability and higher maintenance requirements in dynamic settings.

Safety and Risk Management Considerations

Autonomous mobile robots (AMRs) feature advanced sensors and real-time navigation systems that enhance safety by dynamically detecting obstacles and human presence, reducing collision risks compared to Automated Guided Vehicles (AGVs), which rely on fixed paths and predefined routes. Risk management for AMRs incorporates continuous environmental mapping and adaptive response mechanisms, providing superior flexibility in complex, dynamic environments, whereas AGVs require extensive infrastructure and route safety validation to mitigate operational hazards. Ensuring compliance with industry safety standards such as ISO 3691-4 is critical for both AMRs and AGVs to maintain workplace safety and reduce accident liability.

Applications and Use Cases in Industry

Autonomous mobile robots (AMRs) excel in dynamic industrial environments, enabling flexible material handling, complex assembly tasks, and real-time navigation without fixed paths. Automated guided vehicles (AGVs) are primarily used for repetitive, high-volume transport in warehouses or manufacturing lines, following predetermined routes to optimize efficiency and safety. AMRs support adaptive logistics and just-in-time delivery systems, while AGVs are ideal for streamlined, predictable workflows in large-scale production facilities.

Future Trends: Evolution of Mobile Robotics in Manufacturing

Autonomous mobile robots (AMRs) are expected to surpass automated guided vehicles (AGVs) in flexibility and intelligence, leveraging AI and advanced sensor fusion for dynamic navigation within manufacturing environments. The integration of 5G connectivity and edge computing will enable real-time data processing, enhancing decision-making and operational efficiency in mobile robotics. Future trends indicate a shift towards collaborative robots that seamlessly interact with human workers, optimizing production workflows and adapting to complex, evolving industrial demands.

Fleet management systems

Autonomous mobile robots utilize advanced fleet management systems with real-time data analytics and dynamic task allocation, whereas automated guided vehicles rely on fixed-path coordination and centralized control for fleet management.

Dynamic path planning

Autonomous mobile robots utilize advanced dynamic path planning algorithms to navigate unpredictable environments, while automated guided vehicles rely on pre-defined, fixed paths limiting their adaptability.

Natural feature navigation

Autonomous mobile robots leverage natural feature navigation using advanced sensors and AI for dynamic pathfinding, whereas automated guided vehicles rely on fixed infrastructure and predefined routes for navigation.

Fixed-path guidance

Autonomous mobile robots use advanced sensors and AI for dynamic navigation beyond fixed-path guidance, whereas automated guided vehicles rely on predetermined routes such as magnetic strips or wires for fixed-path navigation.

Multi-agent coordination

Autonomous mobile robots outperform automated guided vehicles in multi-agent coordination by enabling dynamic path planning, adaptive task allocation, and real-time communication for optimized fleet productivity.

SLAM (Simultaneous Localization and Mapping)

Autonomous mobile robots utilize advanced SLAM algorithms to dynamically map and navigate complex environments, whereas automated guided vehicles typically rely on fixed-path guidance systems with limited or no SLAM capabilities.

Magnetic tape guidance

Autonomous mobile robots use advanced sensors and AI for dynamic navigation, while automated guided vehicles rely on magnetic tape guidance for fixed, predefined routes.

Obstacle avoidance algorithms

Autonomous mobile robots employ advanced real-time obstacle avoidance algorithms using sensors like LIDAR and computer vision, enabling dynamic path planning, while automated guided vehicles primarily rely on predefined routes with basic obstacle detection systems.

Adaptive routing

Autonomous mobile robots utilize adaptive routing with real-time environment mapping and dynamic path planning, while automated guided vehicles rely on fixed, predefined routes for navigation.

Facilities layout integration

Autonomous mobile robots seamlessly navigate complex facilities layouts using advanced sensors and AI, offering flexible path planning and dynamic obstacle avoidance, while automated guided vehicles rely on fixed tracks or wires, limiting layout adaptability and requiring extensive infrastructure modifications.

Autonomous mobile robots vs Automated guided vehicles Infographic

njnir.com

njnir.com