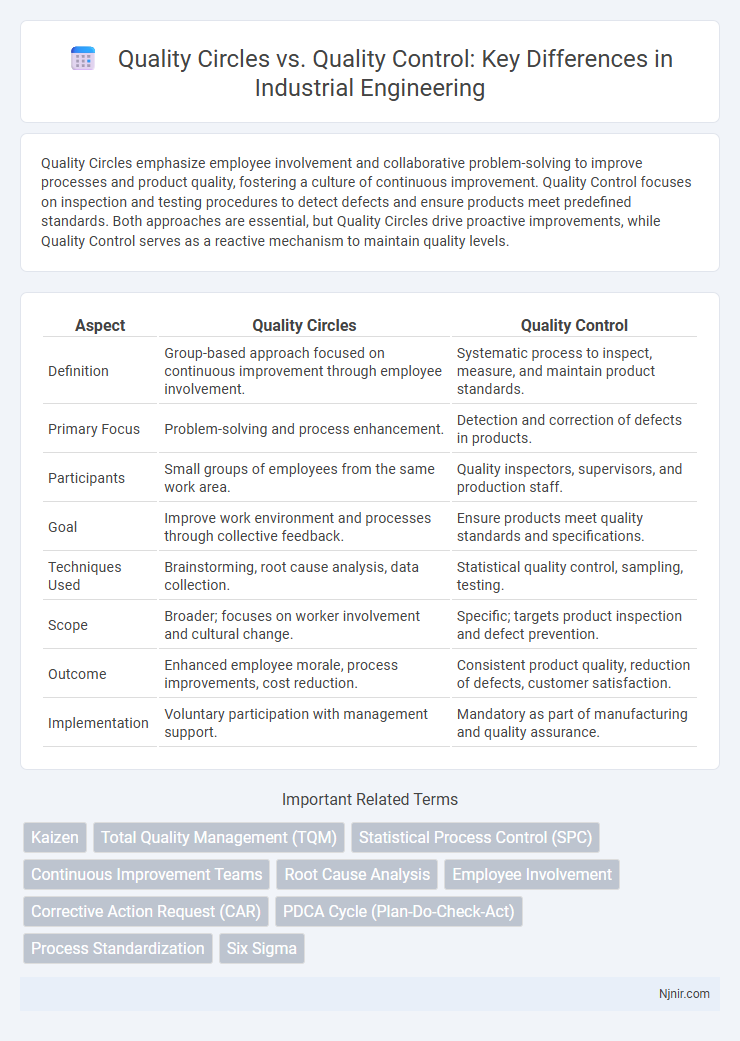

Quality Circles emphasize employee involvement and collaborative problem-solving to improve processes and product quality, fostering a culture of continuous improvement. Quality Control focuses on inspection and testing procedures to detect defects and ensure products meet predefined standards. Both approaches are essential, but Quality Circles drive proactive improvements, while Quality Control serves as a reactive mechanism to maintain quality levels.

Table of Comparison

| Aspect | Quality Circles | Quality Control |

|---|---|---|

| Definition | Group-based approach focused on continuous improvement through employee involvement. | Systematic process to inspect, measure, and maintain product standards. |

| Primary Focus | Problem-solving and process enhancement. | Detection and correction of defects in products. |

| Participants | Small groups of employees from the same work area. | Quality inspectors, supervisors, and production staff. |

| Goal | Improve work environment and processes through collective feedback. | Ensure products meet quality standards and specifications. |

| Techniques Used | Brainstorming, root cause analysis, data collection. | Statistical quality control, sampling, testing. |

| Scope | Broader; focuses on worker involvement and cultural change. | Specific; targets product inspection and defect prevention. |

| Outcome | Enhanced employee morale, process improvements, cost reduction. | Consistent product quality, reduction of defects, customer satisfaction. |

| Implementation | Voluntary participation with management support. | Mandatory as part of manufacturing and quality assurance. |

Introduction to Quality Circles and Quality Control

Quality Circles are small groups of employees who voluntarily meet regularly to identify, analyze, and solve workplace problems, fostering a culture of continuous improvement and employee involvement. Quality Control involves systematic processes and techniques used to monitor, measure, and ensure that products or services meet specified standards and customer expectations. Both concepts aim to enhance organizational quality, but Quality Circles emphasize employee participation while Quality Control focuses on product compliance and defect prevention.

Defining Quality Circles in Industrial Engineering

Quality Circles in Industrial Engineering are small groups of workers who voluntarily meet to identify, analyze, and solve work-related problems, improving product quality and operational efficiency. Unlike Quality Control, which is a formal inspection process focused on detecting defects in products, Quality Circles emphasize employee involvement, continuous improvement, and collaborative problem-solving. These teams use tools such as root cause analysis and brainstorming to foster innovation and enhance workplace morale.

Core Principles of Quality Control

Quality Control centers on systematically monitoring and evaluating products to ensure they meet predefined standards, emphasizing defect detection and prevention through rigorous inspection and testing methodologies. Core principles include adherence to defined quality standards, consistent process control, and corrective actions based on objective data analysis. Unlike Quality Circles, which foster employee-driven problem-solving and continuous improvement, Quality Control operates as a formalized, top-down approach focused on compliance and reliability.

Key Differences: Quality Circles vs Quality Control

Quality Circles are small groups of employees who voluntarily meet to identify, analyze, and solve work-related problems, emphasizing employee involvement and continuous improvement. Quality Control refers to the systematic process of inspecting, testing, and monitoring products or services to ensure they meet specified quality standards. The key difference lies in Quality Circles fostering collaborative problem-solving and employee participation, while Quality Control focuses on maintaining quality by detecting and correcting defects through formal procedures.

Objectives and Goals: Aligning with Organizational Quality

Quality Circles aim to engage employees in continuous improvement and problem-solving to enhance overall organizational quality and foster teamwork. Quality Control focuses on inspecting and testing products or services to ensure they meet established standards and prevent defects. Both approaches align with organizational quality by promoting high standards, but Quality Circles emphasize proactive employee involvement, while Quality Control emphasizes reactive quality assurance.

Implementation Processes: Quality Circles vs Quality Control

Quality Circles involve employee-driven implementation processes through regular group meetings aimed at identifying and solving workplace problems, promoting continuous improvement and employee engagement. Quality Control focuses on systematic inspection and testing procedures, using statistical tools and standards to ensure products meet predefined specifications and reduce defects. Implementation of Quality Circles requires strong organizational culture and training in problem-solving, whereas Quality Control demands technical expertise and structured quality assurance protocols.

Employee Involvement and Participation

Quality Circles emphasize active employee involvement and participation by encouraging small groups of workers to identify and solve workplace problems collaboratively, fostering a culture of continuous improvement. Quality Control typically involves a structured process managed by designated quality specialists to monitor and maintain product standards, with limited direct employee input. The participatory nature of Quality Circles enhances employee engagement and empowerment, contrasting with the more top-down approach of traditional Quality Control systems.

Measuring Effectiveness: Metrics and Outcomes

Quality Circles improve effectiveness by measuring employee participation rates, problem-solving success ratios, and innovation implementation frequency, emphasizing team-driven quality enhancement. Quality Control focuses on defect rates, process compliance percentages, and product inspection pass rates, aiming to maintain predetermined quality standards. Both approaches rely on specific metrics tailored to their methodologies, with Quality Circles fostering continuous improvement and Quality Control ensuring consistent output quality.

Challenges and Limitations in Industrial Settings

Quality Circles face challenges in industrial settings such as employee resistance, lack of management support, and limited training, which hinder their effectiveness in continuous improvement initiatives. Quality Control struggles with limitations including reliance on post-production inspection, inability to prevent defects proactively, and high costs associated with extensive testing and rework. Both approaches require integration and alignment with organizational culture to overcome operational constraints and achieve sustained quality enhancement.

Choosing the Right Approach for Continuous Improvement

Quality Circles emphasize employee-driven problem-solving through small group collaboration to enhance workplace processes, fostering a culture of continuous improvement and employee engagement. Quality Control relies on systematic inspection and testing to detect defects, ensuring products meet predefined standards but may not address underlying process inefficiencies. Selecting the right approach depends on organizational goals, with Quality Circles suited for fostering innovation and sustained improvement, while Quality Control is effective for maintaining product reliability and compliance.

Kaizen

Quality Circles foster continuous improvement through employee-driven Kaizen initiatives, while Quality Control emphasizes systematic inspection and defect prevention.

Total Quality Management (TQM)

Quality Circles foster employee-driven continuous improvement and problem-solving, enhancing Total Quality Management (TQM) by promoting teamwork and innovation, whereas Quality Control emphasizes systematic inspection and defect detection to maintain product standards.

Statistical Process Control (SPC)

Quality Circles enhance team-based problem solving and continuous improvement, while Quality Control employs Statistical Process Control (SPC) techniques to monitor and maintain process stability and product quality.

Continuous Improvement Teams

Continuous Improvement Teams in Quality Circles emphasize employee-driven problem-solving and incremental process enhancements, whereas Quality Control primarily focuses on product inspection and maintaining predefined standards.

Root Cause Analysis

Quality Circles emphasize collaborative Root Cause Analysis among employees to identify process improvements, while Quality Control primarily uses Root Cause Analysis to detect and correct defects through systematic inspection.

Employee Involvement

Quality Circles enhance employee involvement by fostering collaborative problem-solving and continuous improvement, whereas Quality Control primarily relies on managerial oversight and standardized inspections to maintain product standards.

Corrective Action Request (CAR)

Quality Circles foster collaborative problem-solving and proactive improvement, while Quality Control emphasizes the identification and documentation of defects through Corrective Action Requests (CAR) to address and prevent recurring issues.

PDCA Cycle (Plan-Do-Check-Act)

Quality Circles enhance employee collaboration and problem-solving within the PDCA Cycle by fostering continuous improvement, while Quality Control applies the PDCA Cycle to systematically monitor and maintain product standards through structured inspection and corrective actions.

Process Standardization

Quality Circles enhance process standardization through employee-driven continuous improvement, while Quality Control enforces standardized processes by monitoring and inspecting outputs.

Six Sigma

Quality Circles emphasize employee-driven problem-solving teams, while Quality Control involves systematic inspection processes, both integral to Six Sigma's goal of reducing defects through data-driven methodologies.

Quality Circles vs Quality Control Infographic

njnir.com

njnir.com