Industry 4.0 represents the integration of cyber-physical systems, IoT, and real-time data analytics to create interconnected and autonomous manufacturing environments. Smart Manufacturing leverages these Industry 4.0 technologies to optimize production processes, improve flexibility, and enhance decision-making through advanced automation and digital twins. The synergy between Industry 4.0 infrastructure and Smart Manufacturing practices drives increased efficiency, reduced downtime, and customized production capabilities.

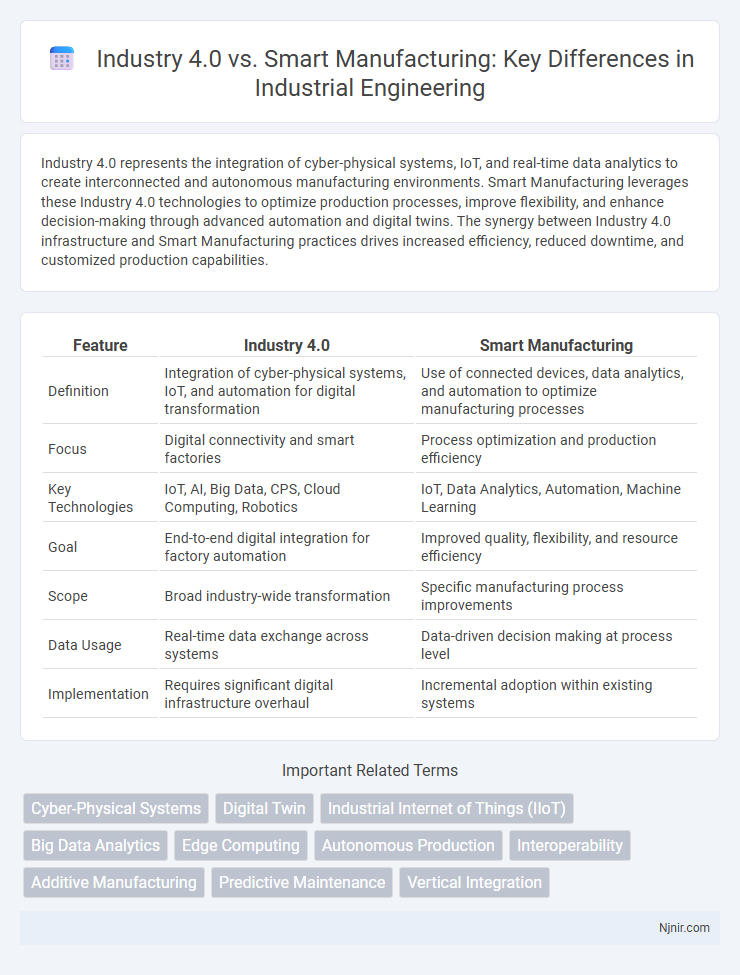

Table of Comparison

| Feature | Industry 4.0 | Smart Manufacturing |

|---|---|---|

| Definition | Integration of cyber-physical systems, IoT, and automation for digital transformation | Use of connected devices, data analytics, and automation to optimize manufacturing processes |

| Focus | Digital connectivity and smart factories | Process optimization and production efficiency |

| Key Technologies | IoT, AI, Big Data, CPS, Cloud Computing, Robotics | IoT, Data Analytics, Automation, Machine Learning |

| Goal | End-to-end digital integration for factory automation | Improved quality, flexibility, and resource efficiency |

| Scope | Broad industry-wide transformation | Specific manufacturing process improvements |

| Data Usage | Real-time data exchange across systems | Data-driven decision making at process level |

| Implementation | Requires significant digital infrastructure overhaul | Incremental adoption within existing systems |

Defining Industry 4.0 and Smart Manufacturing

Industry 4.0 refers to the fourth industrial revolution characterized by the integration of cyber-physical systems, IoT, cloud computing, and artificial intelligence to create highly automated and interconnected manufacturing environments. Smart Manufacturing focuses on optimizing production processes through real-time data analytics, adaptive control systems, and advanced robotics to enhance efficiency and flexibility. Both concepts emphasize digital transformation but Industry 4.0 represents a broader ecosystem while Smart Manufacturing concentrates on practical factory-floor applications.

Historical Evolution of Industrial Automation

Industry 4.0 represents the fourth industrial revolution, emphasizing cyber-physical systems, IoT, and real-time data analytics to achieve fully interconnected and autonomous manufacturing processes. Smart Manufacturing builds upon Industry 4.0 principles by integrating advanced sensors, machine learning, and AI to optimize production efficiency, quality, and flexibility. The historical evolution from mechanization in Industry 1.0, through electrification and automation in Industry 2.0 and 3.0, respectively, laid the technological foundation for the digital transformation marked by Industry 4.0 and Smart Manufacturing.

Core Technologies Driving Industry 4.0

Industry 4.0 leverages core technologies such as the Internet of Things (IoT), artificial intelligence (AI), big data analytics, and cyber-physical systems to create interconnected, automated manufacturing environments. Smart manufacturing emphasizes real-time data exchange, advanced robotics, and digital twins to optimize production efficiency and flexibility. Together, these technologies drive enhanced automation, predictive maintenance, and seamless integration across supply chains.

Smart Manufacturing: Key Features and Capabilities

Smart Manufacturing integrates advanced technologies such as IoT, AI, and robotics to optimize production processes, enhance flexibility, and improve product quality in real-time. Key features include digital twin simulations, predictive maintenance, and data-driven decision-making, enabling adaptive manufacturing environments and reduced downtime. These capabilities drive efficiency, resource optimization, and sustainable manufacturing practices, surpassing traditional Industry 4.0 frameworks through comprehensive system integration.

Comparing Industry 4.0 and Smart Manufacturing Concepts

Industry 4.0 emphasizes integrating cyber-physical systems, IoT, and big data analytics to create highly autonomous and interconnected manufacturing environments. Smart Manufacturing focuses on optimizing production processes through real-time data, advanced automation, and adaptive decision-making systems to enhance efficiency and flexibility. While Industry 4.0 represents the broader digital transformation of manufacturing ecosystems, Smart Manufacturing applies these technologies specifically to improve operational performance on the factory floor.

Integration of IoT, AI, and Big Data

Industry 4.0 emphasizes the digital transformation of manufacturing through seamless integration of IoT devices, AI algorithms, and Big Data analytics to create connected, adaptive systems. Smart Manufacturing specifically harnesses these technologies to optimize production efficiency, predictive maintenance, and real-time decision-making on the factory floor. The synergy of IoT sensors collecting data, AI-driven insights, and Big Data platforms enables enhanced automation, flexible operations, and improved product quality in both paradigms.

Impacts on Productivity and Operational Efficiency

Industry 4.0 integrates cyber-physical systems, IoT, and big data analytics to enable real-time decision-making and predictive maintenance, significantly boosting productivity by minimizing downtime and enhancing process automation. Smart manufacturing leverages connected devices, AI, and robotics to optimize workflows and resource utilization, resulting in improved operational efficiency through adaptive production systems and reduced waste. Both paradigms drive transformative impacts, with Industry 4.0 emphasizing digital integration and Smart Manufacturing focusing on intelligent, data-driven manufacturing execution.

Challenges and Risks of Implementation

Industry 4.0 implementation faces challenges such as high initial investment costs, integration of legacy systems, and cybersecurity vulnerabilities. Smart Manufacturing struggles with data interoperability, workforce skill gaps, and real-time decision-making reliability. Both paradigms require robust risk management strategies to address operational disruptions and maintain system resilience.

Case Studies: Industry 4.0 vs Smart Manufacturing in Action

Case studies showcasing Industry 4.0 vs Smart Manufacturing highlight distinct implementation approaches in real-world settings. Industry 4.0 emphasizes interconnected cyber-physical systems, IoT, and data analytics to enable autonomous decision-making and predictive maintenance, as seen in Siemens' Amberg Electronics Plant. In contrast, smart manufacturing focuses on optimizing processes and workforce collaboration through advanced automation and real-time monitoring, exemplified by Toyota's adaptive production systems integrating human expertise with smart robotics.

Future Trends and Roadmap for Industrial Transformation

Industry 4.0 integrates cyber-physical systems, IoT, and AI to create interconnected, autonomous manufacturing environments, while Smart Manufacturing emphasizes data-driven processes and real-time analytics for optimized production. Future trends include the adoption of digital twins, edge computing, and advanced robotics to enhance flexibility, efficiency, and predictive maintenance. The industrial transformation roadmap involves incremental digitization, workforce upskilling, and scalable integration of AI-driven decision-making platforms to achieve sustainable, resilient factories.

Cyber-Physical Systems

Cyber-Physical Systems (CPS) are the foundational technology distinguishing Industry 4.0 from traditional Smart Manufacturing by integrating real-time data, advanced sensors, and automated control systems to enable seamless interaction between physical processes and digital networks.

Digital Twin

Digital Twin technology enhances Industry 4.0 and Smart Manufacturing by enabling real-time simulation, monitoring, and optimization of production processes for increased efficiency and reduced downtime.

Industrial Internet of Things (IIoT)

Industry 4.0 leverages Industrial Internet of Things (IIoT) to enable smart manufacturing by integrating real-time data analytics, automation, and interconnected devices for optimized production efficiency and predictive maintenance.

Big Data Analytics

Industry 4.0 leverages Big Data Analytics to enhance interconnected systems, while Smart Manufacturing applies these insights to optimize real-time production processes.

Edge Computing

Edge computing enhances Industry 4.0 and Smart Manufacturing by enabling real-time data processing at the source, reducing latency, improving operational efficiency, and supporting advanced automation technologies.

Autonomous Production

Autonomous production in Industry 4.0 leverages advanced AI, IoT, and cyber-physical systems to enable self-optimizing manufacturing processes, distinguishing it from traditional smart manufacturing by emphasizing real-time adaptability and minimal human intervention.

Interoperability

Industry 4.0 emphasizes advanced digital integration across cyber-physical systems, enabling seamless interoperability in smart manufacturing through standardized communication protocols and real-time data exchange.

Additive Manufacturing

Additive manufacturing enhances Industry 4.0 and smart manufacturing by enabling precise, on-demand production with real-time data integration, optimized supply chains, and reduced waste.

Predictive Maintenance

Industry 4.0 integrates IoT and AI technologies to enable predictive maintenance in smart manufacturing, reducing downtime and optimizing asset performance.

Vertical Integration

Vertical integration in Industry 4.0 enhances smart manufacturing by seamlessly connecting all production layers from IoT devices to enterprise resource planning systems, improving real-time data flow and operational efficiency.

Industry 4.0 vs Smart Manufacturing Infographic

njnir.com

njnir.com