Flexible Manufacturing Systems (FMS) prioritize adaptability by enabling rapid changes in production processes to accommodate small batch sizes and customized products, enhancing efficiency in variable demand environments. Mass Production emphasizes high-volume output with standardized processes, optimizing cost and time efficiency for uniform products but lacking flexibility. Implementing FMS allows industries to respond quickly to market fluctuations, while mass production excels in maximizing output and minimizing unit costs for consistent goods.

Table of Comparison

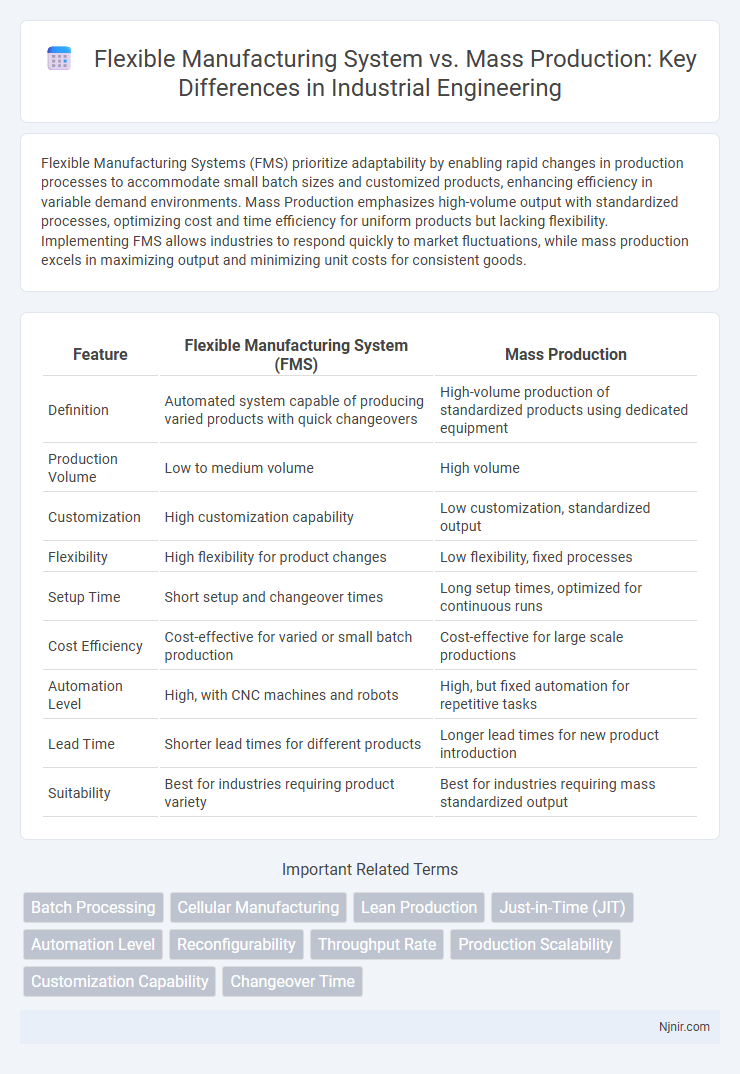

| Feature | Flexible Manufacturing System (FMS) | Mass Production |

|---|---|---|

| Definition | Automated system capable of producing varied products with quick changeovers | High-volume production of standardized products using dedicated equipment |

| Production Volume | Low to medium volume | High volume |

| Customization | High customization capability | Low customization, standardized output |

| Flexibility | High flexibility for product changes | Low flexibility, fixed processes |

| Setup Time | Short setup and changeover times | Long setup times, optimized for continuous runs |

| Cost Efficiency | Cost-effective for varied or small batch production | Cost-effective for large scale productions |

| Automation Level | High, with CNC machines and robots | High, but fixed automation for repetitive tasks |

| Lead Time | Shorter lead times for different products | Longer lead times for new product introduction |

| Suitability | Best for industries requiring product variety | Best for industries requiring mass standardized output |

Introduction to Flexible Manufacturing Systems (FMS) and Mass Production

Flexible Manufacturing Systems (FMS) integrate computer-controlled machines, robotics, and automated material handling to enable high flexibility in low to medium volume production, adapting swiftly to design changes and varied product types. Mass Production emphasizes standardized, high-volume output with dedicated machinery focused on efficiency and cost reduction for uniform products. FMS offers customizable manufacturing with shorter setup times, contrasting mass production's rigid processes that prioritize scale and consistent product quality.

Historical Evolution of Manufacturing Methods

Flexible Manufacturing Systems (FMS) emerged in the late 20th century as a response to the limitations of traditional mass production, emphasizing adaptability and customization over large-scale repetitive manufacturing. Mass production, pioneered during the Industrial Revolution, revolutionized manufacturing by introducing assembly lines and standardized parts, significantly increasing output and reducing costs. The shift from rigid mass production to FMS reflects advancements in computer technologies and automation, enabling dynamic reconfiguration of production processes to meet diverse market demands efficiently.

Core Principles of Flexible Manufacturing Systems

Flexible Manufacturing Systems (FMS) prioritize adaptability by integrating computer-controlled machines and automated material handling to produce diverse products with minimal downtime. Core principles include modular design, allowing quick reconfiguration of manufacturing cells, and seamless communication between equipment to enable real-time adjustments and efficient resource allocation. Unlike mass production, which emphasizes high-volume output of standardized products, FMS focuses on customization, reduced lead times, and responsiveness to market changes.

Key Characteristics of Mass Production

Mass production is characterized by high-volume output of standardized products using assembly line techniques and specialized machinery to minimize unit costs and increase efficiency. It relies heavily on repetitive tasks, fixed workflows, and economies of scale to deliver consistent quality with minimal variation. Labor specialization and long production runs are essential to achieving fast throughput and reduced per-unit costs in mass production systems.

Flexibility and Customization Capabilities

Flexible Manufacturing Systems (FMS) offer superior flexibility and customization capabilities compared to traditional mass production by enabling rapid switching between different product types and personalized specifications without significant downtime. FMS utilizes advanced robotics and computer-controlled machines, allowing manufacturers to efficiently produce small batch sizes and accommodate variations, which is not feasible in high-volume, uniform mass production lines. This adaptability reduces lead times and enhances responsiveness to market demands, making FMS ideal for industries requiring diverse product offerings and quick customization.

Cost Efficiency and Economies of Scale Comparison

Flexible Manufacturing Systems (FMS) offer cost efficiency by reducing setup times and allowing rapid changes in production without significant downtime, making them ideal for low to medium volume, high variety production. Mass production achieves superior economies of scale by producing large volumes of standardized products, significantly lowering per-unit costs through bulk purchasing, labor specialization, and optimized workflows. While mass production excels in cost reduction for homogeneous products, FMS provides a versatile approach that balances customization and cost efficiency in dynamic market environments.

Technological Requirements and Automation Levels

Flexible Manufacturing Systems (FMS) require advanced computer-aided design (CAD), computer-aided manufacturing (CAM), and robotic automation technologies to enable quick changeovers and real-time production adjustments. Mass production relies on high levels of automation with dedicated machinery designed for continuous, large-scale output but lacks the adaptability of FMS. The technological infrastructure in FMS emphasizes programmable automation and integration of sensors for flexibility, whereas mass production prioritizes rigid automation optimized for efficiency and volume.

Workforce Skills and Labor Considerations

Flexible Manufacturing Systems (FMS) require a highly skilled workforce with expertise in robotics, computer programming, and system diagnostics to manage complex machinery and adapt to varying production needs. In contrast, Mass Production relies heavily on repetitive manual labor with minimal skill requirements, emphasizing efficiency and economies of scale over versatility. Labor considerations in FMS include higher wages and continual training investments, while Mass Production typically involves lower labor costs but higher worker turnover due to monotonous tasks.

Production Lead Time and Responsiveness

Flexible Manufacturing Systems (FMS) significantly reduce production lead time by enabling rapid changeovers and customized batch sizes, which enhances responsiveness to market demand fluctuations. In contrast, mass production typically involves longer lead times due to rigid, large-scale setups optimized for high-volume, standardized output with limited ability to adapt quickly. The agility of FMS in adjusting production schedules and product variations results in faster response to customer requirements compared to the slower, less flexible mass production processes.

Future Trends: Integrating FMS in Modern Industry

Flexible Manufacturing Systems (FMS) are increasingly integrated into modern industry to enhance production adaptability and efficiency, contrasting with traditional mass production's fixed processes. Future trends emphasize smart automation, IoT connectivity, and AI-driven decision-making within FMS to enable real-time customization and reduced downtime. This integration supports sustainable manufacturing and rapid response to market changes, positioning FMS as a pivotal technology for Industry 4.0 transformations.

Batch Processing

Flexible Manufacturing Systems enable efficient batch processing by quickly adapting to different product types, unlike mass production which focuses on continuous, high-volume output with limited variability.

Cellular Manufacturing

Cellular manufacturing in Flexible Manufacturing Systems enhances customization and reduces lead times by grouping similar processes into cells, contrasting with mass production's focus on high-volume, standardized output through assembly lines.

Lean Production

Flexible Manufacturing Systems enable Lean Production by minimizing waste and adapting quickly to product variations, whereas Mass Production emphasizes high-volume output with less customization and efficiency in material usage.

Just-in-Time (JIT)

Flexible Manufacturing Systems enhance Just-in-Time (JIT) production by enabling rapid product changeovers and minimizing inventory, whereas Mass Production typically relies on high-volume output with larger inventory buffers that may reduce JIT effectiveness.

Automation Level

Flexible Manufacturing Systems feature high automation with adaptable machinery for custom production, while Mass Production relies on fixed, highly automated processes optimized for large volume output.

Reconfigurability

Flexible Manufacturing Systems offer superior reconfigurability compared to mass production by enabling rapid adaptation to product changes and customization without extensive downtime or cost.

Throughput Rate

Flexible Manufacturing Systems optimize throughput rate by enabling rapid product changeovers and minimizing downtime, whereas Mass Production achieves high throughput through continuous, standardized processes with limited flexibility.

Production Scalability

Flexible Manufacturing Systems enable rapid production scalability by easily adjusting to varying product volumes, whereas Mass Production offers high output efficiency but with limited adaptability to scale changes.

Customization Capability

Flexible Manufacturing Systems enable high customization capability by allowing quick product changes, whereas Mass Production offers limited customization due to standardized, large-scale processes.

Changeover Time

Flexible Manufacturing Systems minimize changeover time through automated tooling adjustments, while Mass Production experiences longer changeover times due to manual setup processes.

Flexible Manufacturing System vs Mass Production Infographic

njnir.com

njnir.com