Automated Guided Vehicles (AGVs) follow fixed paths using wires or magnets embedded in the floor, offering reliable and predictable material transport in industrial environments. Autonomous Mobile Robots (AMRs) leverage advanced sensors and AI to navigate dynamically, adapting to changing layouts and obstacles for increased flexibility. AMRs provide enhanced scalability and efficiency, while AGVs excel in highly structured processes requiring consistent routes.

Table of Comparison

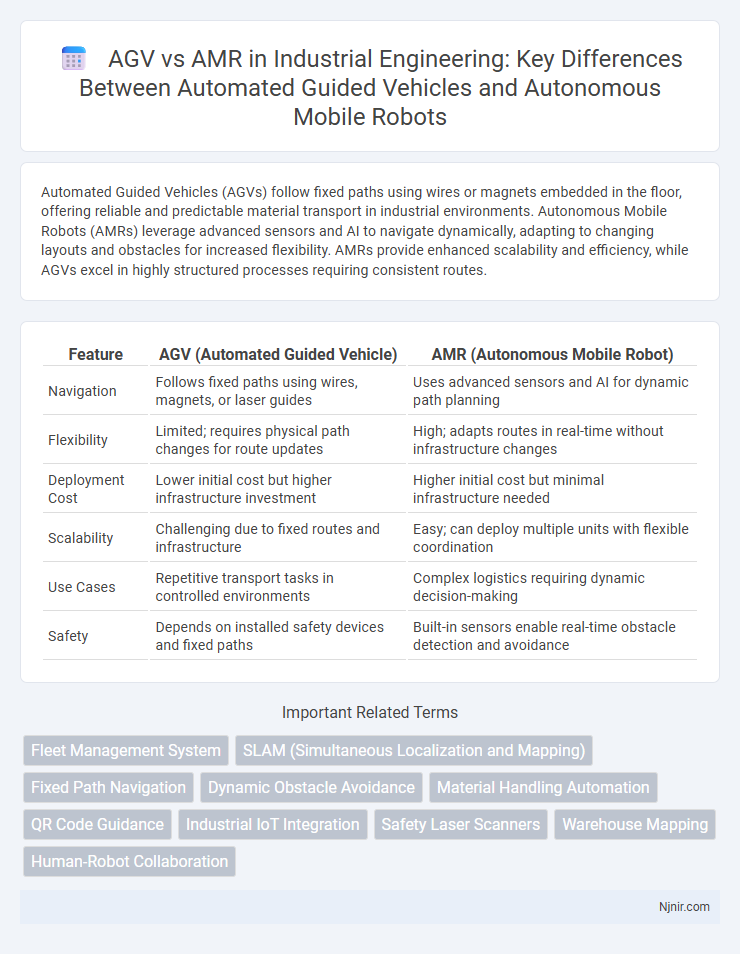

| Feature | AGV (Automated Guided Vehicle) | AMR (Autonomous Mobile Robot) |

|---|---|---|

| Navigation | Follows fixed paths using wires, magnets, or laser guides | Uses advanced sensors and AI for dynamic path planning |

| Flexibility | Limited; requires physical path changes for route updates | High; adapts routes in real-time without infrastructure changes |

| Deployment Cost | Lower initial cost but higher infrastructure investment | Higher initial cost but minimal infrastructure needed |

| Scalability | Challenging due to fixed routes and infrastructure | Easy; can deploy multiple units with flexible coordination |

| Use Cases | Repetitive transport tasks in controlled environments | Complex logistics requiring dynamic decision-making |

| Safety | Depends on installed safety devices and fixed paths | Built-in sensors enable real-time obstacle detection and avoidance |

Introduction to AGV and AMR Technologies

Automated Guided Vehicles (AGVs) utilize pre-defined paths marked by physical guides such as magnetic tapes, wires, or sensors to transport materials within industrial environments, ensuring precise navigation but limited flexibility. Autonomous Mobile Robots (AMRs) leverage advanced sensors, AI, and SLAM (Simultaneous Localization and Mapping) technology to dynamically interpret their surroundings and optimize routes in real-time, enabling adaptive and efficient material handling. Both AGVs and AMRs are integral to modern automation, with AGVs excelling in repetitive, controlled tasks and AMRs providing greater agility in complex, changing environments.

Core Differences Between AGVs and AMRs

AGVs (Automated Guided Vehicles) rely on fixed navigation paths using physical markers like wires or magnetic strips, limiting their operational flexibility, while AMRs (Autonomous Mobile Robots) utilize advanced sensors and AI for dynamic path planning and obstacle avoidance. AGVs require pre-defined infrastructure and are best suited for repetitive, linear tasks, whereas AMRs can adapt to changing environments and complex workflows without external guidance systems. The core difference lies in the level of autonomy, with AMRs offering greater independence and scalability in modern logistics and manufacturing environments.

Navigation Methods: Fixed Path vs Dynamic Routing

Automated Guided Vehicles (AGVs) use fixed path navigation methods such as magnetic tapes, wires, or predefined tracks, enabling precise, repetitive movements ideal for structured environments like warehouses or manufacturing floors. Autonomous Mobile Robots (AMRs) rely on dynamic routing through advanced sensors, LiDAR, and AI-powered mapping to navigate changing environments independently, offering flexibility in complex or unpredictable settings. The fundamental distinction lies in AGVs' reliance on rigid, pre-installed paths versus AMRs' ability to dynamically adapt routes in real-time, optimizing efficiency and operational adaptability.

Flexibility and Adaptability in Industrial Environments

AGVs follow fixed, predefined paths using physical guides like wires or magnetic strips, limiting their flexibility in dynamic industrial environments. AMRs leverage advanced sensors and AI-driven navigation, enabling them to adapt routes in real-time around obstacles and changes on the factory floor. This inherent adaptability makes AMRs ideal for evolving production lines and complex logistics, providing superior operational efficiency compared to traditional AGVs.

Safety Features and Risk Management

AGVs (Automated Guided Vehicles) rely on fixed routes and embedded sensors for navigation, emphasizing robust safety measures like emergency stop buttons, safety bumpers, and laser scanners to prevent collisions in controlled environments. AMRs (Autonomous Mobile Robots) use advanced AI and real-time mapping to navigate dynamically, incorporating sophisticated obstacle detection, predictive analytics, and adaptive path planning to mitigate risks in complex, changing settings. Risk management in AGVs prioritizes predefined safe zones and physical barriers, whereas AMRs focus on continuous environment assessment and autonomous decision-making to enhance workplace safety.

Integration with Existing Industrial Systems

AGVs typically require predefined paths and fixed infrastructure such as magnetic strips or wires, which can complicate integration with dynamic industrial systems. AMRs leverage advanced sensors and artificial intelligence to navigate flexibly around obstacles, enabling smoother incorporation into existing workflows without extensive modifications. This adaptability allows AMRs to optimize material handling by interfacing seamlessly with warehouse management and manufacturing execution systems.

Cost Analysis and Return on Investment

AGVs (Automated Guided Vehicles) typically incur lower initial costs due to simpler infrastructure requirements but lack the flexibility of AMRs (Autonomous Mobile Robots), which require higher upfront investment for advanced sensors and AI systems. Over time, AMRs offer a better return on investment (ROI) through increased adaptability, reduced downtime, and scalability in dynamic environments, enhancing operational efficiency. Cost analysis should factor in maintenance expenses, system scalability, and production impact to determine the most financially viable solution for specific industrial applications.

Use Cases and Industry Applications

Automated Guided Vehicles (AGVs) excel in repetitive, predefined routes within industries like manufacturing, warehousing, and automotive assembly, offering reliability in transporting materials along fixed pathways. Autonomous Mobile Robots (AMRs) provide flexible navigation using sensors and AI, ideal for dynamic environments such as e-commerce fulfillment centers, healthcare logistics, and retail inventory management where adaptability is crucial. Both AGVs and AMRs improve operational efficiency, but AMRs lead in scenarios requiring real-time path planning and obstacle avoidance.

Future Trends in Industrial Automation

AGVs and AMRs are transforming industrial automation with distinct future trends shaping their adoption; AGVs continue to provide reliable, fixed-path material handling solutions ideal for repetitive tasks, while AMRs offer advanced sensor integration and AI-driven navigation for dynamic, flexible environments. The rise of Industry 4.0 demands seamless integration of AMRs with IoT platforms, real-time data analytics, and cloud-based fleet management to optimize operational efficiency. Machine learning enhancements and collaborative robot (cobot) capabilities will further blur the lines between AGV and AMR functionalities, driving smarter, more adaptive automated transport systems in manufacturing and warehouse logistics.

Choosing the Right Solution: AGV or AMR?

Choosing the right solution between AGV (Automated Guided Vehicle) and AMR (Autonomous Mobile Robot) depends on operational needs and environmental complexity. AGVs follow fixed paths using sensors like magnetic strips or wires, offering reliability in structured, repetitive tasks within controlled environments such as warehouses or manufacturing floors. AMRs utilize advanced mapping, AI, and sensor fusion to navigate dynamic, unstructured spaces, making them ideal for flexible, scalable automation requiring obstacle avoidance and real-time decision-making.

Fleet Management System

Fleet management systems for AGVs rely on pre-defined pathways and centralized control, whereas AMR fleet management uses dynamic navigation algorithms and decentralized coordination to optimize flexibility and efficiency.

SLAM (Simultaneous Localization and Mapping)

AMRs leverage advanced SLAM technology for dynamic, real-time mapping and autonomous navigation, whereas AGVs typically rely on fixed-path guidance systems with limited adaptability.

Fixed Path Navigation

Automated Guided Vehicles (AGVs) rely on fixed path navigation using physical guides like wires or magnets, whereas Autonomous Mobile Robots (AMRs) utilize advanced sensors and AI for dynamic route planning without fixed paths.

Dynamic Obstacle Avoidance

Autonomous Mobile Robots (AMRs) utilize advanced sensors and AI-powered algorithms for dynamic obstacle avoidance, enabling real-time navigation around unpredictable obstacles, whereas Automated Guided Vehicles (AGVs) rely on fixed paths and sensors with limited adaptive obstacle detection.

Material Handling Automation

Autonomous Mobile Robots (AMRs) offer greater flexibility and intelligence in material handling automation compared to Automated Guided Vehicles (AGVs), enabling dynamic route planning and adaptation to changing warehouse environments.

QR Code Guidance

AGVs rely on fixed QR code guidance systems for navigation along predetermined paths, while AMRs use QR codes combined with advanced sensors and AI to dynamically navigate complex environments.

Industrial IoT Integration

Industrial IoT integration enables AGVs to follow predefined paths with limited adaptability, while AMRs utilize real-time sensor data and AI for dynamic navigation and enhanced operational flexibility in smart manufacturing environments.

Safety Laser Scanners

Safety laser scanners in Automated Guided Vehicles (AGVs) provide fixed-path obstacle detection, while Autonomous Mobile Robots (AMRs) utilize advanced safety laser scanners for dynamic, real-time navigation and collision avoidance.

Warehouse Mapping

AMRs utilize advanced warehouse mapping technologies like simultaneous localization and mapping (SLAM) to navigate dynamically and autonomously, whereas AGVs rely on fixed guide paths and predefined maps for navigation, limiting flexibility in warehouse operations.

Human-Robot Collaboration

AMRs enhance human-robot collaboration by autonomously navigating dynamic environments with advanced sensors and AI, while AGVs rely on fixed paths and guided systems, limiting flexibility in shared workspaces.

AGV (Automated Guided Vehicle) vs AMR (Autonomous Mobile Robot) Infographic

njnir.com

njnir.com