Simulation modeling allows industrial engineers to create virtual replicas of production processes, enabling analysis and optimization without disrupting actual operations. Real-time monitoring provides continuous data collection from live systems, facilitating immediate detection of anomalies and performance tracking. Combining both approaches enhances decision-making by validating models with real-time data and predicting future scenarios accurately.

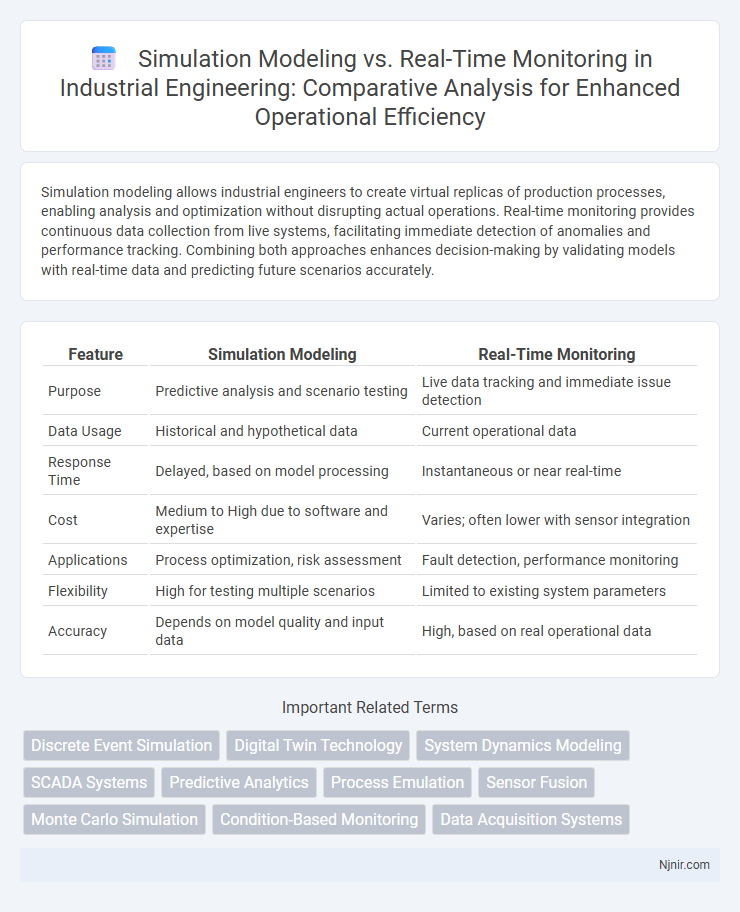

Table of Comparison

| Feature | Simulation Modeling | Real-Time Monitoring |

|---|---|---|

| Purpose | Predictive analysis and scenario testing | Live data tracking and immediate issue detection |

| Data Usage | Historical and hypothetical data | Current operational data |

| Response Time | Delayed, based on model processing | Instantaneous or near real-time |

| Cost | Medium to High due to software and expertise | Varies; often lower with sensor integration |

| Applications | Process optimization, risk assessment | Fault detection, performance monitoring |

| Flexibility | High for testing multiple scenarios | Limited to existing system parameters |

| Accuracy | Depends on model quality and input data | High, based on real operational data |

Introduction to Simulation Modeling and Real-Time Monitoring

Simulation modeling creates virtual environments to analyze system behavior under varied scenarios, enabling prediction and optimization without physical trials. Real-time monitoring gathers live data from operational systems, providing continuous insights for immediate decision-making and issue detection. Both approaches enhance system understanding but differ in application timing and data utilization, with simulation focusing on predictive analysis and real-time monitoring emphasizing current performance tracking.

Key Concepts: Simulation Modeling in Industrial Engineering

Simulation modeling in industrial engineering involves creating digital replicas of manufacturing processes to analyze system behavior under various scenarios, enabling optimization without disrupting actual operations. This technique uses mathematical models and algorithms to predict outcomes, improve system efficiency, and reduce costs. Real-time monitoring complements simulation by providing live data streams, but simulation modeling offers a controlled environment to test process changes before implementation.

Fundamentals of Real-Time Monitoring in Industrial Settings

Real-time monitoring in industrial settings involves continuous data acquisition from sensors and control systems to track equipment performance, process variables, and environmental conditions instantly. This approach enables immediate detection of anomalies, reducing downtime and optimizing operational efficiency by facilitating rapid decision-making and corrective actions. Unlike simulation modeling, which predicts potential outcomes based on hypothetical scenarios, real-time monitoring provides accurate, live data critical for maintaining safety, compliance, and productivity in industrial operations.

Comparative Analysis: Simulation Modeling vs Real-Time Monitoring

Simulation modeling creates virtual environments to predict system behavior under various scenarios, enabling risk assessment and decision-making without affecting actual operations. Real-time monitoring captures live data from physical systems, providing immediate feedback for rapid response and operational adjustments. While simulation offers foresight and strategic planning capabilities, real-time monitoring excels in dynamic, real-world system performance tracking and issue detection.

Advantages of Simulation Modeling for Process Optimization

Simulation modeling offers a powerful advantage for process optimization by enabling detailed analysis of complex systems without interrupting actual operations. It provides predictive insights through scenario testing and what-if analyses, identifying bottlenecks and inefficiencies before implementation. Enhanced decision-making is supported by the ability to evaluate multiple strategies virtually, reducing costs and risks associated with trial-and-error in real-time environments.

Benefits of Real-Time Monitoring for Operational Efficiency

Real-time monitoring enhances operational efficiency by providing immediate data on system performance, enabling swift identification and resolution of issues before they escalate. It supports continuous process optimization through live feedback, reducing downtime and improving resource allocation. Unlike simulation modeling, which predicts outcomes based on hypothetical scenarios, real-time monitoring delivers precise, current insights critical for maintaining optimal operations.

Limitations of Simulation Modeling in Industrial Applications

Simulation modeling in industrial applications often faces limitations such as the inability to capture real-time changes and unforeseen variables, leading to less accurate predictions. Models rely heavily on assumptions and historical data, which may not reflect dynamic operational environments or sudden disruptions. Additionally, the complexity of industrial systems can result in oversimplified simulations that fail to account for intricate interactions and human factors.

Challenges and Constraints of Real-Time Monitoring Systems

Real-time monitoring systems face significant challenges including high data processing demands, latency issues, and the need for robust network infrastructure to ensure continuous data flow. These constraints often lead to difficulties in maintaining accuracy and reliability under dynamic or unpredictable conditions. Unlike simulation modeling, real-time systems must manage hardware limitations and potential sensor failures, which can compromise decision-making processes.

Integrating Simulation Modeling with Real-Time Monitoring

Integrating simulation modeling with real-time monitoring enhances predictive accuracy by continuously updating models with live data streams from sensors and IoT devices. This hybrid approach enables dynamic scenario analysis and immediate anomaly detection, optimizing operational decision-making across manufacturing, energy, and supply chain sectors. Leveraging digital twins powered by real-time data fusion ensures adaptive responses to fluctuating conditions, reducing downtime and improving resource efficiency.

Future Trends in Industrial Engineering: Digital Twin and Smart Manufacturing

Simulation modeling enables virtual testing of industrial processes to predict performance and optimize designs without physical trials, while real-time monitoring captures live data to ensure operational efficiency and immediate problem detection. Future trends in industrial engineering emphasize the integration of Digital Twin technology, combining simulation models with real-time data to create dynamic, intelligent representations of manufacturing systems. This synergy supports smart manufacturing by enhancing predictive maintenance, adaptive control, and data-driven decision-making for improved productivity and reduced downtime.

Discrete Event Simulation

Discrete Event Simulation optimizes complex system analysis by modeling event-driven changes over time, while real-time monitoring provides continuous, live data for immediate decision-making.

Digital Twin Technology

Digital Twin Technology integrates simulation modeling by creating virtual replicas for predictive analysis while enabling real-time monitoring through continuous data synchronization with physical assets.

System Dynamics Modeling

System Dynamics Modeling in simulation offers predictive insights into complex system behaviors over time, unlike real-time monitoring which captures immediate system states without forecasting future outcomes.

SCADA Systems

SCADA systems integrate simulation modeling to predict system behaviors and real-time monitoring to provide live data for efficient industrial process control.

Predictive Analytics

Simulation modeling uses historical data to forecast future scenarios, while real-time monitoring provides live data streams essential for dynamic predictive analytics in decision-making.

Process Emulation

Simulation modeling enables process emulation by creating virtual replicas of systems to predict outcomes, while real-time monitoring tracks actual process performance for immediate adjustments.

Sensor Fusion

Sensor fusion enhances both simulation modeling and real-time monitoring by integrating multi-sensor data to improve accuracy, reliability, and predictive capabilities.

Monte Carlo Simulation

Monte Carlo Simulation provides probabilistic modeling of complex systems compared to real-time monitoring, which offers instantaneous data tracking for dynamic decision-making.

Condition-Based Monitoring

Simulation modeling predicts equipment performance under various scenarios, while real-time monitoring provides continuous data for Condition-Based Monitoring to detect anomalies and optimize maintenance.

Data Acquisition Systems

Data acquisition systems in simulation modeling enable predictive analysis through virtual data generation, while in real-time monitoring they provide continuous, real-world data streams for immediate operational insights.

Simulation modeling vs Real-time monitoring Infographic

njnir.com

njnir.com