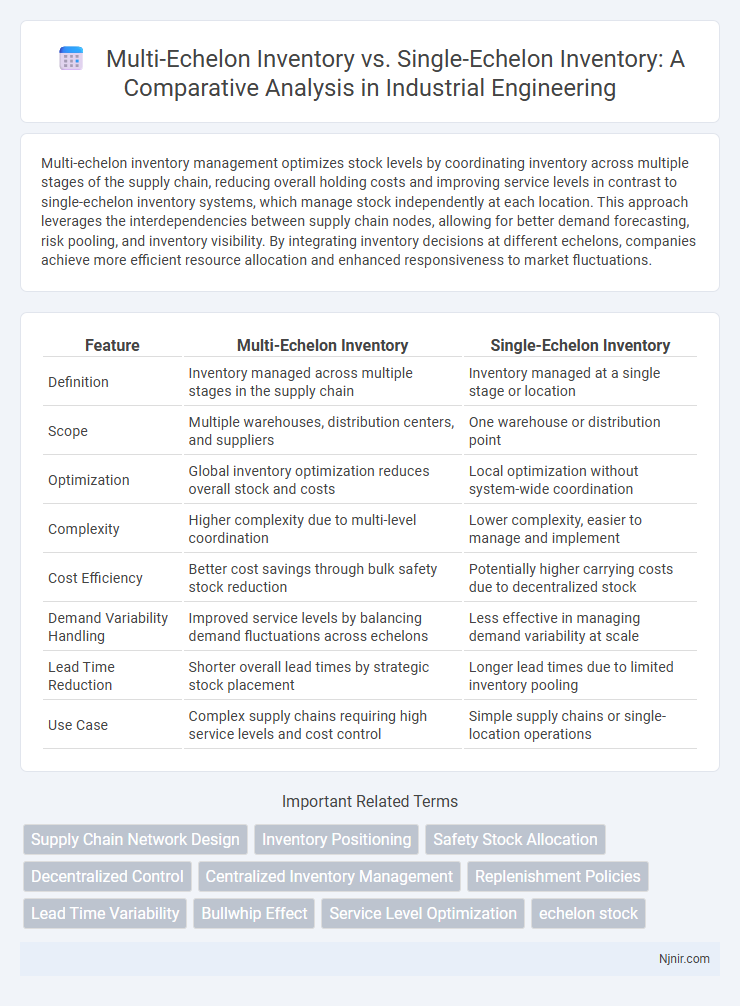

Multi-echelon inventory management optimizes stock levels by coordinating inventory across multiple stages of the supply chain, reducing overall holding costs and improving service levels in contrast to single-echelon inventory systems, which manage stock independently at each location. This approach leverages the interdependencies between supply chain nodes, allowing for better demand forecasting, risk pooling, and inventory visibility. By integrating inventory decisions at different echelons, companies achieve more efficient resource allocation and enhanced responsiveness to market fluctuations.

Table of Comparison

| Feature | Multi-Echelon Inventory | Single-Echelon Inventory |

|---|---|---|

| Definition | Inventory managed across multiple stages in the supply chain | Inventory managed at a single stage or location |

| Scope | Multiple warehouses, distribution centers, and suppliers | One warehouse or distribution point |

| Optimization | Global inventory optimization reduces overall stock and costs | Local optimization without system-wide coordination |

| Complexity | Higher complexity due to multi-level coordination | Lower complexity, easier to manage and implement |

| Cost Efficiency | Better cost savings through bulk safety stock reduction | Potentially higher carrying costs due to decentralized stock |

| Demand Variability Handling | Improved service levels by balancing demand fluctuations across echelons | Less effective in managing demand variability at scale |

| Lead Time Reduction | Shorter overall lead times by strategic stock placement | Longer lead times due to limited inventory pooling |

| Use Case | Complex supply chains requiring high service levels and cost control | Simple supply chains or single-location operations |

Introduction to Inventory Echelons in Industrial Engineering

Multi-echelon inventory systems manage stock across multiple stages of the supply chain, enhancing overall efficiency by balancing inventory levels at warehouses, distribution centers, and retail outlets. Single-echelon inventory focuses on optimizing stock at one stage, often leading to higher safety stock and less coordinated replenishment. Industrial engineering leverages multi-echelon models to minimize total system costs and improve service levels through integrated demand forecasting and inventory control.

Defining Multi-Echelon Inventory Systems

Multi-echelon inventory systems manage stock levels across multiple stages of a supply chain, such as suppliers, warehouses, and retail locations, enabling synchronized replenishment and reduced overall inventory costs. This approach contrasts with single-echelon inventory systems, which optimize inventory at only one level, often leading to inefficiencies and higher safety stock requirements. Multi-echelon inventory optimization incorporates demand variability and lead time variability at each echelon, providing a holistic strategy for inventory control across the entire supply network.

Understanding Single-Echelon Inventory Models

Single-echelon inventory models focus on controlling inventory levels at one stage of the supply chain, optimizing reorder points and order quantities to balance holding costs and service levels. These models simplify demand forecasting and replenishment decisions by managing stock based purely on local demand without considering upstream or downstream inventory positions. Effective single-echelon inventory management enhances responsiveness and reduces carrying costs but may lack the coordination benefits present in multi-echelon inventory systems.

Structural Differences Between Multi- and Single-Echelon Approaches

Multi-echelon inventory systems consist of multiple interconnected stages or locations in the supply chain, such as suppliers, warehouses, and retailers, each managing inventory levels to optimize overall supply chain performance. Single-echelon inventory systems focus on inventory management at one stage or location, treating other stages independently without coordinated replenishment strategies. Structural differences highlight multi-echelon's integrated approach to balancing inventory across network nodes, while single-echelon systems manage stock in isolation, often leading to higher total inventory and less synchronized operations.

Inventory Control Policies: Single vs. Multi-Echelon

Multi-echelon inventory control policies coordinate stock levels across multiple stages, optimizing inventory allocation by considering interdependencies between locations, whereas single-echelon policies manage inventory at individual sites independently, often leading to higher safety stock and inefficiencies. Multi-echelon strategies use advanced algorithms to minimize total system-wide costs, improve service levels, and reduce redundancy by balancing replenishment and demand variability across echelons. In contrast, single-echelon approaches simplify decision-making but fail to capture the complexity of supply chain dynamics, resulting in suboptimal inventory distribution and increased holding costs.

Optimization Techniques for Multi-Echelon Inventory Management

Optimization techniques for multi-echelon inventory management leverage advanced algorithms such as stochastic modeling, dynamic programming, and machine learning to balance inventory levels across multiple supply chain stages. These techniques minimize overall costs and improve service levels by coordinating stock replenishment policies, demand forecasting, and lead-time variability at each echelon. In contrast to single-echelon inventory systems, multi-echelon optimization captures interdependencies between different stages, enabling more precise safety stock calculations and streamlined inventory distribution.

Cost Implications in Multi-Echelon vs. Single-Echelon Systems

Multi-echelon inventory systems optimize stock levels across multiple stages in the supply chain, significantly reducing overall holding and shortage costs compared to single-echelon systems, which manage inventory at individual points independently. By leveraging centralized coordination and demand variability pooling, multi-echelon systems lower safety stock requirements and improve service levels, leading to cost savings in warehousing and capital tied-up in inventory. Single-echelon inventory methods often incur higher total costs due to duplicated safety stocks and less efficient risk pooling across the network.

Demand Forecasting and Uncertainty Handling

Multi-echelon inventory systems leverage demand forecasting across multiple supply chain stages, enhancing accuracy through aggregated data and reducing uncertainty by optimizing stock levels at each node. Single-echelon inventory focuses on independent, localized demand forecasts, which can lead to higher safety stock requirements due to isolated uncertainty management. Integrating advanced demand forecasting techniques in multi-echelon models improves inventory responsiveness and reduces overall system costs by better handling variability across the supply network.

Technology Integration in Inventory Echelon Systems

Multi-echelon inventory systems leverage advanced technology integration such as AI-driven demand forecasting and real-time data analytics to optimize stock levels across multiple locations, enhancing overall supply chain visibility and responsiveness. Single-echelon systems typically rely on localized data and simpler software tools, limiting their ability to coordinate inventory effectively across the network. The adoption of Internet of Things (IoT) devices and cloud-based platforms in multi-echelon inventory management enables dynamic inventory adjustments, reducing costs and improving service levels compared to traditional single-echelon approaches.

Choosing the Right Inventory Echelon Strategy for Industry

Multi-echelon inventory management optimizes stock levels across multiple locations in a supply chain, reducing overall inventory costs and improving service levels by balancing inventory between central warehouses and regional distribution centers. Single-echelon inventory focuses on managing stock at a single location, simplifying inventory tracking but often resulting in higher safety stock and increased risk of stockouts or overstocking. Industries with complex distribution networks or high demand variability benefit more from multi-echelon strategies, while single-echelon systems suit businesses with straightforward supply chains and limited warehousing points.

Supply Chain Network Design

Multi-echelon inventory systems optimize supply chain network design by coordinating stock levels across multiple locations to reduce overall inventory costs and improve service levels compared to single-echelon systems that manage inventory independently at each site.

Inventory Positioning

Multi-echelon inventory optimizes inventory positioning across multiple supply chain layers to minimize total costs and improve service levels, whereas single-echelon inventory manages stock only at individual locations without coordinated optimization.

Safety Stock Allocation

Multi-echelon inventory optimizes safety stock allocation by coordinating stock levels across multiple stages in the supply chain, reducing overall inventory costs and improving service levels compared to single-echelon inventory systems that manage safety stock independently at each stage.

Decentralized Control

Decentralized control in multi-echelon inventory systems enhances responsiveness and flexibility by allowing independent decision-making at each stage, unlike single-echelon systems where centralized control limits adaptive inventory management.

Centralized Inventory Management

Centralized inventory management in multi-echelon inventory systems optimizes stock levels across multiple locations, reducing overall holding costs and improving service levels compared to single-echelon inventory systems that manage stock individually at each location.

Replenishment Policies

Multi-echelon inventory replenishment policies coordinate stock levels across multiple locations to optimize overall supply chain performance, unlike single-echelon policies that focus solely on individual site replenishment.

Lead Time Variability

Multi-echelon inventory systems mitigate lead time variability impact more effectively than single-echelon systems by coordinating stock levels across multiple locations, reducing stockouts and excess inventory.

Bullwhip Effect

Multi-echelon inventory systems effectively reduce the Bullwhip Effect by coordinating stock levels across multiple supply chain stages, unlike single-echelon inventory which often amplifies demand variability and increases cost inefficiencies.

Service Level Optimization

Multi-echelon inventory optimizes service levels by balancing stock across multiple supply chain stages, reducing overall inventory costs and improving product availability compared to single-echelon inventory systems.

echelon stock

Multi-echelon inventory optimizes echelon stock across multiple supply chain stages to reduce overall inventory costs and improve service levels, whereas single-echelon inventory manages stock at individual locations without coordinating across tiers.

Multi-echelon inventory vs Single-echelon inventory Infographic

njnir.com

njnir.com