Line balancing optimizes workflow by evenly distributing tasks across workstations to minimize idle time and improve productivity. Load leveling, known as production smoothing, aims to reduce fluctuations in production volume to maintain a steady workflow and avoid bottlenecks. Both techniques enhance operational efficiency but focus on different aspects: line balancing targets task distribution, while load leveling addresses production stability.

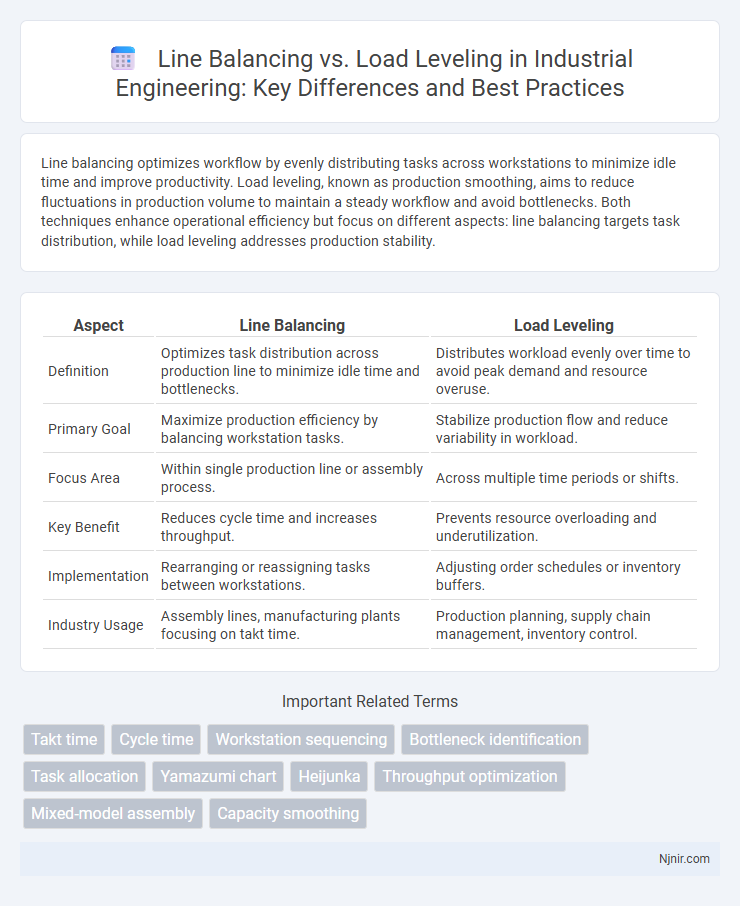

Table of Comparison

| Aspect | Line Balancing | Load Leveling |

|---|---|---|

| Definition | Optimizes task distribution across production line to minimize idle time and bottlenecks. | Distributes workload evenly over time to avoid peak demand and resource overuse. |

| Primary Goal | Maximize production efficiency by balancing workstation tasks. | Stabilize production flow and reduce variability in workload. |

| Focus Area | Within single production line or assembly process. | Across multiple time periods or shifts. |

| Key Benefit | Reduces cycle time and increases throughput. | Prevents resource overloading and underutilization. |

| Implementation | Rearranging or reassigning tasks between workstations. | Adjusting order schedules or inventory buffers. |

| Industry Usage | Assembly lines, manufacturing plants focusing on takt time. | Production planning, supply chain management, inventory control. |

Introduction to Line Balancing and Load Leveling

Line balancing involves distributing tasks evenly across workstations to optimize production flow and minimize idle time, enhancing operational efficiency and reducing bottlenecks. Load leveling, also known as production smoothing, focuses on maintaining a consistent workload by adjusting production rates to match demand fluctuations, preventing overburdening and underutilization of resources. Both methods aim to improve manufacturing efficiency but address different aspects of workflow management--line balancing optimizes task allocation, while load leveling manages production variability.

Core Concepts: Defining Line Balancing

Line balancing involves distributing tasks evenly across workstations to optimize production flow and minimize idle time, ensuring each station has a similar amount of work. Load leveling, or production smoothing, focuses on stabilizing production volume and workload over time to reduce fluctuations and improve efficiency. Defining line balancing centers on the core concept of assigning tasks sequentially while maintaining a balanced workload to achieve continuous workflow and high utilization.

Core Concepts: Understanding Load Leveling

Load leveling, also known as production leveling or Heijunka, involves distributing production volume and variety evenly over time to reduce fluctuations and inefficiencies in manufacturing processes. This core concept focuses on stabilizing workflow, minimizing inventory buildup, and enhancing resource utilization by smoothing demand peaks and troughs. Unlike line balancing, which allocates tasks to workstations to optimize cycle time, load leveling emphasizes consistent production rates to achieve operational efficiency and predictability.

Key Objectives: Efficiency vs. Stability

Line balancing aims to optimize production efficiency by evenly distributing tasks across workstations to minimize idle time and bottlenecks. Load leveling focuses on achieving operational stability by smoothing production flow and maintaining consistent workload to prevent resource overuse and downtime. Both strategies enhance manufacturing performance but prioritize efficiency in task allocation versus stability in demand management.

Techniques Used in Line Balancing

Line balancing techniques primarily involve task assignment, precedence diagram analysis, and cycle time calculation to evenly distribute work across workstations, minimizing idle time and bottlenecks. Methods such as the Largest Candidate Rule, Kilbridge and Wester, and Ranked Positional Weights optimize station loads by prioritizing tasks based on duration and dependencies. These techniques ensure efficient workflow synchronization and improve overall production efficiency compared to load leveling, which focuses more on inventory and demand smoothing.

Methods Applied in Load Leveling

Load leveling methods primarily involve smoothing production by distributing workload evenly over time to avoid bottlenecks and idle resources, employing techniques like finite capacity scheduling and demand forecasting. These approaches balance demand with available capacity through inventory buffering, workforce flexibility, and production rate adjustments. In contrast to line balancing, which focuses on task allocation within assembly lines, load leveling optimizes overall workflow stability across multiple processes or shifts.

Comparative Analysis: Line Balancing vs. Load Leveling

Line balancing optimizes workstation assignments to minimize idle time and ensure smooth workflow within production lines, directly impacting cycle time and efficiency. Load leveling, also known as Heijunka, distributes production volume and variety evenly over a given period, reducing inventory buildup and lead time variability. While line balancing focuses on task allocation for operational efficiency, load leveling emphasizes demand stabilization and capacity utilization across production schedules.

Practical Applications in Manufacturing

Line balancing optimizes workflow by evenly distributing tasks across workstations, enhancing production efficiency and minimizing idle time in assembly lines. Load leveling focuses on smoothing production volume and mix to reduce bottlenecks and inventory buildup, ensuring steady resource utilization and consistent output. Both techniques improve manufacturing processes by addressing different aspects of operational efficiency--line balancing targets task allocation, while load leveling manages production variability.

Challenges and Limitations

Line balancing faces challenges in dealing with variable task times and worker skill levels, resulting in bottlenecks and idle time that reduce overall efficiency. Load leveling struggles with demand fluctuations and production variability, making it difficult to maintain a steady workflow and optimal resource utilization. Both methods have limitations in adapting to dynamic manufacturing environments and require continuous adjustments to maintain productivity.

Best Practices and Future Trends

Effective line balancing optimizes workflow by distributing tasks evenly across production stations, minimizing bottlenecks and reducing idle time. Load leveling, also known as production smoothing, focuses on stabilizing production volume to match demand fluctuations, improving inventory management and resource utilization. Emerging trends integrate AI-driven analytics and real-time data monitoring for adaptive line balancing and automated load leveling, enhancing operational agility and predictive efficiency.

Takt time

Line balancing optimizes workload distribution based on Takt time to ensure each task fits within cycle time, while load leveling smooths production flow by adjusting demand to match capacity without directly using Takt time.

Cycle time

Line balancing optimizes cycle time by evenly distributing tasks across workstations to minimize idle time, while load leveling smooths production flow by adjusting workload over time to reduce fluctuations in cycle time.

Workstation sequencing

Workstation sequencing optimizes line balancing by arranging tasks to evenly distribute workload, while load leveling smooths production flow by adjusting task timing to prevent bottlenecks.

Bottleneck identification

Line balancing optimizes task distribution to prevent bottlenecks, while load leveling smooths workflow to identify and mitigate bottlenecks in production processes.

Task allocation

Line balancing optimizes task allocation by evenly distributing workloads across workstations to minimize idle time, while load leveling focuses on smoothing task allocation over time to prevent bottlenecks and resource overuse.

Yamazumi chart

Yamazumi charts visually optimize line balancing by identifying task imbalances and cycle time discrepancies, whereas load leveling focuses on distributing work evenly over time to reduce bottlenecks and maintain steady workflow.

Heijunka

Heijunka optimizes production efficiency by implementing line balancing through load leveling to minimize waste and ensure consistent workflow.

Throughput optimization

Line balancing optimizes throughput by evenly distributing tasks across workstations to minimize idle time, while load leveling enhances throughput by smoothing production schedules to reduce bottlenecks and fluctuations in workload.

Mixed-model assembly

In mixed-model assembly, line balancing optimizes workstation task distribution to minimize cycle time, while load leveling evenly distributes production volume across time to reduce inventory and labor fluctuations.

Capacity smoothing

Capacity smoothing in line balancing evenly distributes work tasks to minimize idle time, whereas load leveling adjusts production rates to stabilize capacity utilization and avoid bottlenecks.

line balancing vs load leveling Infographic

njnir.com

njnir.com