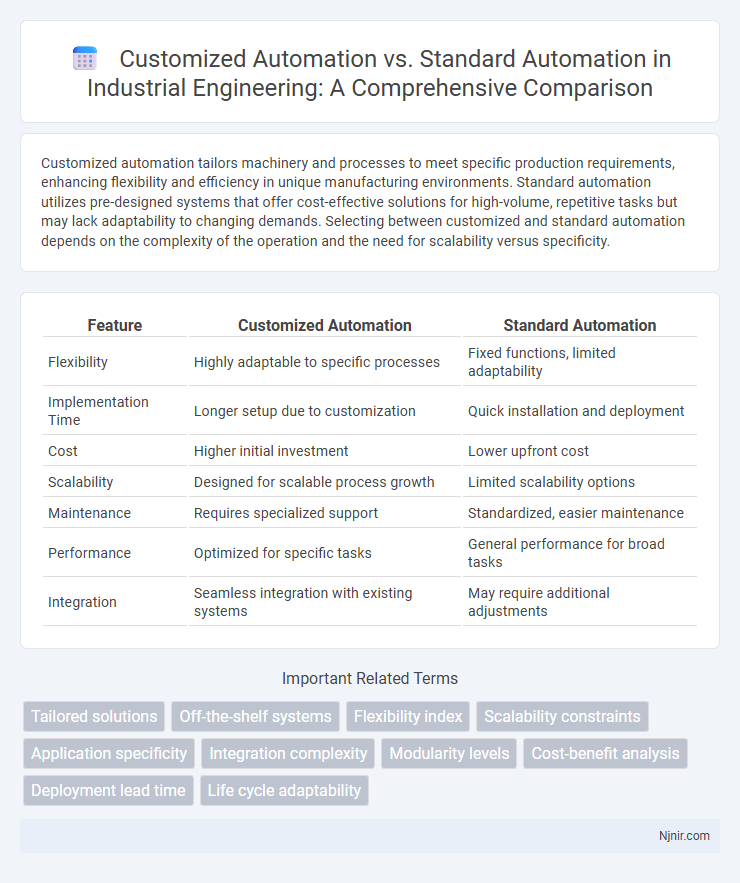

Customized automation tailors machinery and processes to meet specific production requirements, enhancing flexibility and efficiency in unique manufacturing environments. Standard automation utilizes pre-designed systems that offer cost-effective solutions for high-volume, repetitive tasks but may lack adaptability to changing demands. Selecting between customized and standard automation depends on the complexity of the operation and the need for scalability versus specificity.

Table of Comparison

| Feature | Customized Automation | Standard Automation |

|---|---|---|

| Flexibility | Highly adaptable to specific processes | Fixed functions, limited adaptability |

| Implementation Time | Longer setup due to customization | Quick installation and deployment |

| Cost | Higher initial investment | Lower upfront cost |

| Scalability | Designed for scalable process growth | Limited scalability options |

| Maintenance | Requires specialized support | Standardized, easier maintenance |

| Performance | Optimized for specific tasks | General performance for broad tasks |

| Integration | Seamless integration with existing systems | May require additional adjustments |

Overview of Customized vs Standard Automation

Customized automation offers tailored solutions designed to meet specific business processes and unique operational requirements, enhancing flexibility and scalability. Standard automation relies on pre-built, generic workflows that streamline common tasks but may lack adaptability for specialized needs. Choosing between the two depends on the complexity of processes, integration capabilities, and long-term scalability goals.

Key Differences in Implementation

Customized automation requires tailored programming and integration to meet specific business workflows, often involving higher upfront costs and longer development times. Standard automation leverages pre-built, off-the-shelf solutions with fixed functionalities that enable faster deployment and lower initial investment but may lack flexibility. Implementation of customized systems demands thorough analysis and close collaboration with stakeholders, while standard automation relies on predefined best practices and minimal customization.

Cost Implications and ROI Analysis

Customized automation often requires higher upfront investment due to tailored design and integration efforts, but it delivers optimized efficiency and scalability aligned with specific business processes, leading to greater long-term ROI. Standard automation features lower initial costs and faster deployment but may lack flexibility, resulting in potential inefficiencies and higher operational expenses over time. Comprehensive ROI analysis should weigh initial capital expenditure against projected productivity gains, maintenance costs, and adaptability to evolving workflows.

Flexibility and Scalability Considerations

Customized automation offers superior flexibility by tailoring solutions to specific business processes, enabling seamless adaptation to unique operational needs and future changes. Standard automation provides scalability through pre-built, repeatable modules designed for broad applicability across industries, but often lacks the ability to easily modify workflows without vendor intervention. When assessing automation strategies, evaluating the balance between customization flexibility and scalability potential is critical for long-term efficiency and growth.

Impact on Production Efficiency

Customized automation tailors processes to specific production needs, significantly enhancing efficiency by reducing downtime and minimizing errors. Standard automation offers scalability and quicker implementation, but may lack the flexibility required for optimizing complex or unique workflows. Choosing customized solutions leads to higher production throughput and better resource utilization in specialized manufacturing environments.

Integration with Existing Systems

Customized automation offers seamless integration with existing systems by tailoring workflows and APIs to specific business infrastructure, ensuring high compatibility and reduced operational disruptions. Standard automation solutions often rely on predefined connectors and may require significant adjustments or middleware to fit legacy systems, potentially leading to integration challenges and increased costs. Enterprises prioritizing efficiency benefit from customized automation's ability to align directly with current IT environments and data architectures.

Maintenance and Support Requirements

Customized automation demands specialized maintenance due to unique system architectures and proprietary components, often requiring highly skilled technicians for troubleshooting and updates. Standard automation benefits from widespread industry support and standardized parts, enabling quicker repairs and cost-effective maintenance through established protocols. Maintenance efficiency and support scalability are typically higher in standard automation systems, reducing downtime and overall service expenses.

Industry-Specific Applications

Customized automation offers tailored solutions designed to address the unique processes and regulatory requirements of specific industries such as pharmaceuticals, automotive, and food processing, enhancing precision and compliance. Standard automation provides general-purpose tools suitable for a variety of applications but may lack the specialization necessary for complex industry-specific tasks. Industry-specific applications benefit from customized automation by improving operational efficiency, reducing errors, and enabling seamless integration with specialized equipment and workflows.

Decision Criteria for Automation Selection

Customized automation excels in addressing unique operational needs and complex workflows, offering tailored solutions that enhance efficiency in specific contexts. Standard automation provides cost-effective, quick deployment options suitable for repetitive, well-defined tasks with minimal variation. Decision criteria for automation selection should include process complexity, budget constraints, scalability requirements, and integration compatibility with existing systems.

Future Trends in Industrial Automation

Future trends in industrial automation emphasize the shift towards customized automation solutions, driven by advances in AI, machine learning, and IoT integration that enable more adaptive, scalable, and efficient systems tailored to specific production needs. Standard automation continues to evolve with improved modularity and interoperability standards, supporting rapid deployment and cost-effective scalability in diverse industrial environments. The convergence of edge computing and real-time data analytics further enhances both customized and standard automation by optimizing performance and predictive maintenance capabilities.

Tailored solutions

Tailored automation solutions provide customized workflows and integrations that enhance efficiency and scalability beyond the one-size-fits-all capabilities of standard automation systems.

Off-the-shelf systems

Off-the-shelf automation systems offer cost-effective, quick deployment with predefined features, while customized automation provides tailored workflows and scalability to meet specific business needs.

Flexibility index

Customized automation offers a higher Flexibility Index by allowing tailored workflows and adaptive processes compared to the fixed structure of Standard automation.

Scalability constraints

Customized automation offers greater flexibility tailored to specific business needs but often faces scalability constraints due to complexity and maintenance challenges compared to standard automation solutions.

Application specificity

Customized automation offers tailored solutions optimized for specific application requirements, whereas standard automation provides generic frameworks with limited adaptability to unique application needs.

Integration complexity

Customized automation increases integration complexity due to tailored coding and system-specific adjustments, while standard automation simplifies integration with predefined, uniform protocols.

Modularity levels

Customized automation offers higher modularity levels with tailored components for specific tasks, while standard automation relies on fixed, pre-designed modules that limit adaptability.

Cost-benefit analysis

Customized automation often involves higher initial costs but delivers greater long-term ROI through tailored efficiency and scalability compared to standard automation's lower upfront expenses and limited adaptability.

Deployment lead time

Customized automation reduces deployment lead time by tailoring solutions to specific needs, whereas standard automation offers faster initial deployment but may require additional adjustments over time.

Life cycle adaptability

Customized automation offers superior life cycle adaptability by enabling tailored updates and scalability, whereas standard automation provides limited flexibility restricted to predefined configurations.

Customized automation vs Standard automation Infographic

njnir.com

njnir.com