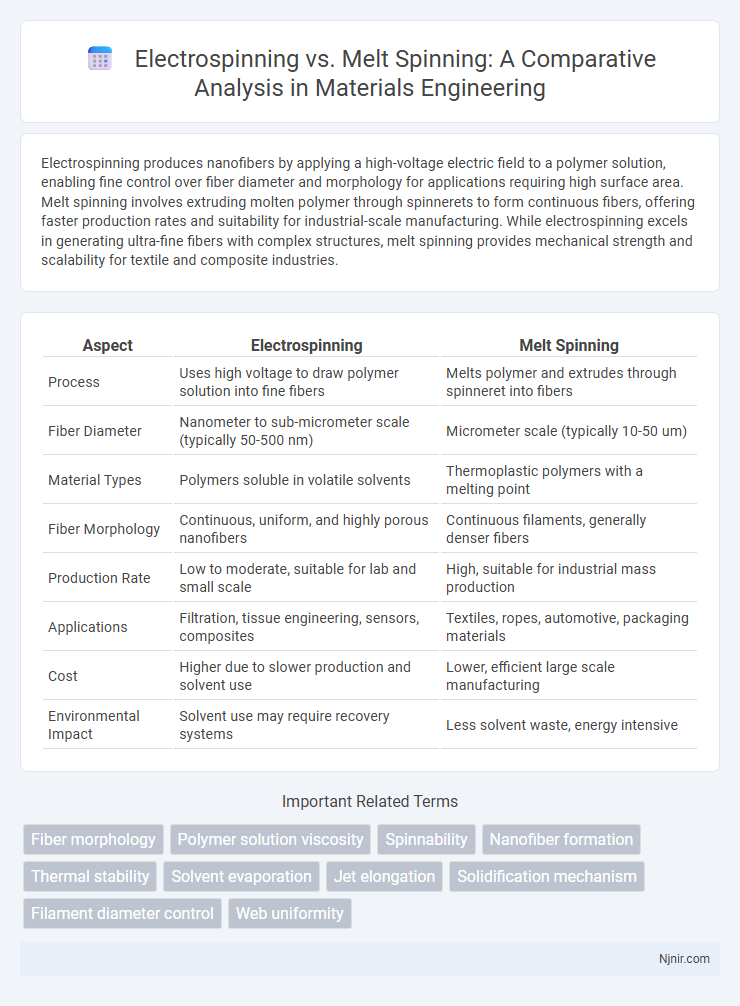

Electrospinning produces nanofibers by applying a high-voltage electric field to a polymer solution, enabling fine control over fiber diameter and morphology for applications requiring high surface area. Melt spinning involves extruding molten polymer through spinnerets to form continuous fibers, offering faster production rates and suitability for industrial-scale manufacturing. While electrospinning excels in generating ultra-fine fibers with complex structures, melt spinning provides mechanical strength and scalability for textile and composite industries.

Table of Comparison

| Aspect | Electrospinning | Melt Spinning |

|---|---|---|

| Process | Uses high voltage to draw polymer solution into fine fibers | Melts polymer and extrudes through spinneret into fibers |

| Fiber Diameter | Nanometer to sub-micrometer scale (typically 50-500 nm) | Micrometer scale (typically 10-50 um) |

| Material Types | Polymers soluble in volatile solvents | Thermoplastic polymers with a melting point |

| Fiber Morphology | Continuous, uniform, and highly porous nanofibers | Continuous filaments, generally denser fibers |

| Production Rate | Low to moderate, suitable for lab and small scale | High, suitable for industrial mass production |

| Applications | Filtration, tissue engineering, sensors, composites | Textiles, ropes, automotive, packaging materials |

| Cost | Higher due to slower production and solvent use | Lower, efficient large scale manufacturing |

| Environmental Impact | Solvent use may require recovery systems | Less solvent waste, energy intensive |

Introduction to Fiber Spinning Techniques

Electrospinning creates ultrafine fibers by applying a high-voltage electric field to a polymer solution or melt, resulting in nanofibers with high surface area and porosity. Melt spinning involves extruding molten polymer through spinnerets to form continuous fibers, commonly used for synthetic fibers like polyester and nylon. Both techniques differ in fiber diameter control, material versatility, and application scope within textile manufacturing and advanced material fields.

Fundamentals of Electrospinning

Electrospinning utilizes an electric field to draw charged polymer jets from a solution or melt, forming ultrafine fibers with diameters ranging from nanometers to micrometers, unlike melt spinning, which relies on extrusion of molten polymers through spinnerets. The key components in electrospinning include a high-voltage power supply, a syringe with polymer solution, and a grounded collector, enabling controlled fiber morphology and alignment. This technique allows for the production of nonwoven mats with high surface area-to-volume ratios, ideal for applications in filtration, tissue engineering, and drug delivery.

Principles of Melt Spinning

Melt spinning involves heating a polymer until it melts, then extruding the molten polymer through a spinneret to form continuous filaments that solidify upon cooling. This process relies on the thermoplastic behavior of polymers, allowing fibers to be produced without solvents. Key parameters include extrusion temperature, cooling rate, and take-up speed, which influence fiber diameter and mechanical properties.

Comparative Advantages: Electrospinning vs Melt Spinning

Electrospinning enables the production of ultra-fine nanofibers with high surface area-to-volume ratios, ideal for applications requiring enhanced filtration, biomedical scaffolds, and functional textiles. Melt spinning offers faster production rates and cost efficiency by extruding molten polymers without solvents, making it suitable for mass manufacturing of standard fibers like polyester and nylon. Electrospinning provides superior control over fiber morphology and material versatility, whereas melt spinning excels in scalability and mechanical strength of continuous filaments.

Material Compatibility and Versatility

Electrospinning offers superior material compatibility by accommodating a wide range of polymers, including those sensitive to heat, due to its solvent-based fiber formation process. Melt spinning primarily suits thermoplastics that can be melted without degradation, such as polypropylene and polyester, limiting its versatility with heat-sensitive materials. The ability of electrospinning to produce nanofibers from diverse polymers enhances its application scope compared to the more restricted thermal processing requirements of melt spinning.

Fiber Morphology and Structural Differences

Electrospinning produces ultrafine fibers with diameters ranging from nanometers to micrometers, characterized by a high surface area and porous morphology due to the rapid solvent evaporation during fiber formation. Melt spinning generates thicker fibers, typically in the micrometer range, with smoother surfaces and more uniform cross-sectional shapes, resulting from the polymer being extruded and solidified through controlled cooling. Structural differences arise as electrospun fibers often form nonwoven mats with random orientation, while melt-spun fibers can be aligned, providing enhanced tensile strength and greater control over mechanical properties.

Production Scalability and Industrial Applications

Electrospinning offers precise control over fiber diameter and morphology but faces challenges in production scalability due to slower throughput and complexity in scaling up equipment. Melt spinning excels in large-scale manufacturing with high production rates, making it ideal for mass-produced textiles and industrial fibers like polypropylene and polyester. Industrial applications favor melt spinning for bulk fiber production in sectors such as automotive and apparel, while electrospinning is preferred for specialized uses including filtration, tissue engineering, and nanofiber mats where fine fiber control is critical.

Environmental Considerations and Energy Efficiency

Electrospinning operates at room temperature, significantly reducing energy consumption compared to melt spinning, which requires high temperatures to melt polymers. Melt spinning produces fewer chemical emissions but consumes more electricity due to heating elements, while electrospinning often uses volatile solvents that necessitate proper ventilation and solvent recovery systems to minimize environmental impact. The choice between these methods influences sustainability outcomes in polymer fiber production, with electrospinning offering energy-efficient advantages when solvent management is optimized.

Recent Innovations and Emerging Trends

Recent innovations in electrospinning emphasize nanofiber functionalization and advanced needleless systems, enhancing scalability and material properties for biomedical and filtration applications. Melt spinning trends focus on sustainable polymers and high-throughput manufacturing, driven by eco-friendly thermoplastics and improved thermal management techniques. Both technologies increasingly integrate smart materials and real-time monitoring for precision fiber fabrication and tailored end-use performance.

Future Prospects in Fiber Spinning Technologies

Electrospinning offers unparalleled control over fiber diameter and morphology, enabling development of nanofibers for advanced biomedical, filtration, and energy applications, driving future innovation in precision fiber design. Melt spinning remains vital for high-throughput production of synthetic fibers like polyester and nylon, with ongoing advancements aiming at enhancing spinning speed and reducing environmental impacts through energy-efficient processes. Integration of smart materials and hybrid spinning techniques promises a transformative future combining the scalability of melt spinning with the nanoscale precision of electrospinning for next-generation fiber technologies.

Fiber morphology

Electrospinning produces ultrafine fibers with high surface area and porous morphology, while melt spinning yields larger, smoother fibers with uniform diameter and less porosity.

Polymer solution viscosity

Electrospinning requires a polymer solution viscosity typically between 1 and 20 Pa*s to form uniform nanofibers, whereas melt spinning operates with much lower viscosity ranges around 103 to 106 Pa*s due to the polymer being in a molten state.

Spinnability

Electrospinning offers superior spinnability for producing ultrafine fibers from polymer solutions with precise diameter control, whereas melt spinning requires polymers with specific melt flow properties for continuous fiber formation but typically results in coarser fibers.

Nanofiber formation

Electrospinning produces uniform nanofibers with diameters typically ranging from 50 to 500 nanometers using high-voltage electric fields, whereas melt spinning yields larger microfibers by extruding molten polymer through a spinneret without electric field-induced elongation.

Thermal stability

Melt spinning offers higher thermal stability than electrospinning due to its ability to process polymers at elevated temperatures without degradation, making it suitable for producing heat-resistant fibers.

Solvent evaporation

Electrospinning relies on rapid solvent evaporation to form fine fibers from polymer solutions, whereas melt spinning eliminates solvent use by directly extruding molten polymers.

Jet elongation

Electrospinning produces nanofibers with higher jet elongation due to electrostatic forces stretching the polymer jet, whereas melt spinning relies on mechanical drawing with lower elongation capacity.

Solidification mechanism

Electrospinning solidifies fibers through rapid solvent evaporation, whereas melt spinning relies on cooling and crystallization of the polymer melt.

Filament diameter control

Electrospinning allows precise control of filament diameter at the nanoscale by adjusting voltage and solution parameters, whereas melt spinning typically produces micrometer-scale fibers with less diameter variability.

Web uniformity

Electrospinning produces nanofiber webs with superior uniformity and finer fiber diameter distribution compared to melt spinning, which often results in coarser and less consistent fiber webs.

Electrospinning vs Melt spinning Infographic

njnir.com

njnir.com