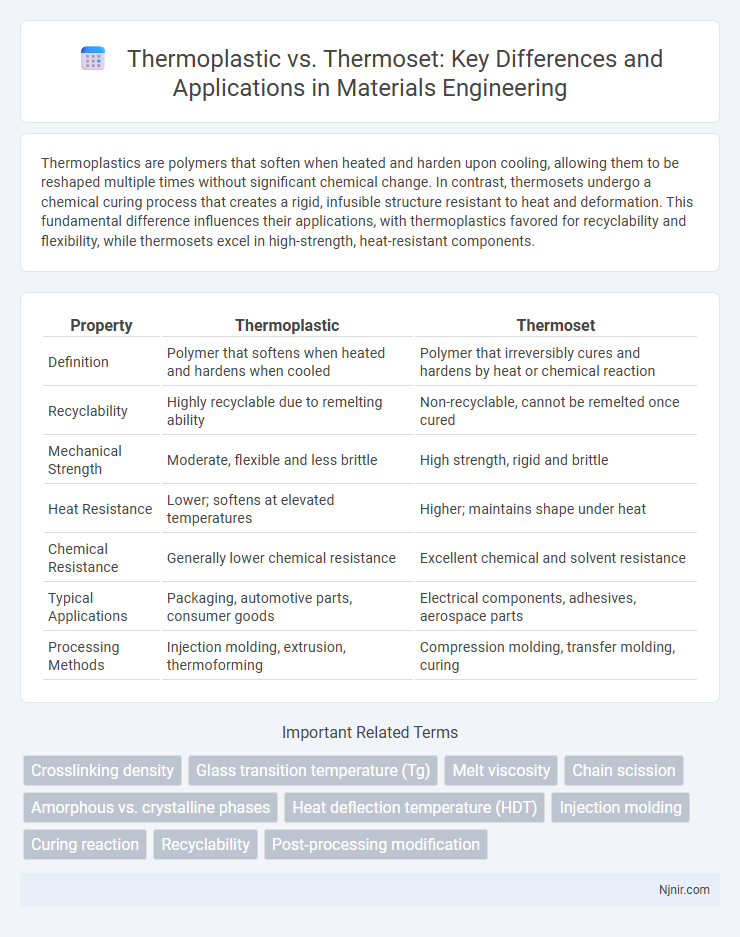

Thermoplastics are polymers that soften when heated and harden upon cooling, allowing them to be reshaped multiple times without significant chemical change. In contrast, thermosets undergo a chemical curing process that creates a rigid, infusible structure resistant to heat and deformation. This fundamental difference influences their applications, with thermoplastics favored for recyclability and flexibility, while thermosets excel in high-strength, heat-resistant components.

Table of Comparison

| Property | Thermoplastic | Thermoset |

|---|---|---|

| Definition | Polymer that softens when heated and hardens when cooled | Polymer that irreversibly cures and hardens by heat or chemical reaction |

| Recyclability | Highly recyclable due to remelting ability | Non-recyclable, cannot be remelted once cured |

| Mechanical Strength | Moderate, flexible and less brittle | High strength, rigid and brittle |

| Heat Resistance | Lower; softens at elevated temperatures | Higher; maintains shape under heat |

| Chemical Resistance | Generally lower chemical resistance | Excellent chemical and solvent resistance |

| Typical Applications | Packaging, automotive parts, consumer goods | Electrical components, adhesives, aerospace parts |

| Processing Methods | Injection molding, extrusion, thermoforming | Compression molding, transfer molding, curing |

Introduction to Thermoplastics and Thermosets

Thermoplastics consist of polymer chains that soften when heated and harden upon cooling, allowing repeated reshaping without significant chemical change, making them ideal for injection molding and 3D printing applications. Thermosets form irreversible chemical bonds during curing, creating rigid, heat-resistant structures that maintain strength under high temperatures and resist deformation, common in electrical insulators and automotive parts. Understanding the molecular behavior of thermoplastics versus thermosets aids in selecting the appropriate material for mechanical durability, thermal stability, and manufacturing process efficiency.

Molecular Structure and Chemical Bonds

Thermoplastics consist of linear or branched polymer chains with weak van der Waals forces or hydrogen bonds, allowing them to soften and reshape upon heating. Thermosets feature a heavily cross-linked molecular structure with strong covalent bonds, creating a rigid, three-dimensional network that prevents melting and deformation after curing. This fundamental difference in chemical bonding results in thermoplastics being recyclable and moldable, while thermosets offer superior mechanical strength and thermal stability.

Key Material Properties Comparison

Thermoplastics exhibit high flexibility, excellent impact resistance, and can be repeatedly melted and reshaped due to their linear polymer chains, making them ideal for applications requiring recyclability and formability. Thermosets possess superior thermal stability, chemical resistance, and mechanical strength because of their cross-linked polymer networks, which provide dimensional stability and resistance to deformation under heat. The distinct differences in melting behavior, with thermoplastics softening upon reheating and thermosets maintaining structural integrity without melting, crucially influence their suitability in various industrial applications.

Processing Methods and Techniques

Thermoplastic materials undergo processes such as injection molding, extrusion, and thermoforming, which allow them to be repeatedly heated, reshaped, and cooled without altering their chemical structure. In contrast, thermoset materials require curing techniques like compression molding, transfer molding, and reaction injection molding, where irreversible chemical cross-linking occurs during heating, resulting in a rigid, set shape. The ability of thermoplastics to be re-melted enables faster production cycles and recycling options, while thermosets offer superior heat resistance and structural stability due to their permanent molecular bonds formed during processing.

Mechanical Performance and Durability

Thermoplastics exhibit superior toughness and flexibility, allowing them to withstand repeated mechanical stress without significant degradation, while thermosets offer higher rigidity and resistance to heat and chemicals due to their cross-linked molecular structure. In terms of durability, thermosets maintain their mechanical properties under high thermal conditions and resist creep and deformation over time, making them ideal for structural and high-performance applications. Thermoplastics, though less resistant to high temperatures, excel in applications requiring impact resistance and repeated thermal cycling, providing extended service life through their ability to be remelted and reformed.

Thermal Stability and Heat Resistance

Thermoplastic polymers exhibit lower thermal stability and heat resistance compared to thermoset polymers, softening or melting when exposed to elevated temperatures due to their linear or branched molecular structures. Thermoset polymers possess a rigid, cross-linked molecular network that provides superior thermal stability and heat resistance, maintaining mechanical integrity at temperatures often exceeding 200degC. This makes thermosets ideal for high-temperature applications in automotive, aerospace, and electronics industries where prolonged heat exposure occurs.

Recycling and Environmental Impact

Thermoplastics are highly recyclable due to their ability to be melted and reshaped multiple times, which reduces landfill waste and conserves resources. In contrast, thermosets cannot be remelted or reshaped after curing, making them difficult to recycle and often leading to increased environmental burden. The environmental impact of thermoplastics is generally lower because their recyclability supports circular economy practices, whereas thermoset disposal commonly involves incineration or landfilling, contributing to pollution.

Applications in Various Industries

Thermoplastics, known for their flexibility and recyclability, are widely used in automotive components, packaging, and consumer electronics due to their ease of molding and durability. Thermosets, characterized by their heat resistance and dimensional stability, dominate applications in aerospace, electrical insulation, and adhesives where structural integrity under high stress is critical. Industries leverage thermoplastics for lightweight, impact-resistant products, while thermosets provide superior thermal and chemical resistance necessary for high-performance industrial parts.

Cost Analysis and Economic Considerations

Thermoplastics generally offer lower initial tooling and processing costs due to their recyclability and faster cycle times, making them more economical for high-volume production runs. Thermosets, while typically more expensive in terms of raw material cost and longer curing times, provide superior mechanical properties and thermal resistance, justifying higher expenditures in applications requiring durability and heat endurance. Overall cost analysis must factor in long-term performance, scrap rates, and lifecycle expenses, where thermoplastics reduce waste and energy consumption but thermosets may minimize replacement frequency and maintenance costs.

Future Trends and Material Innovations

Future trends in thermoplastics emphasize enhanced recyclability and lightweight composites, driving innovations such as bio-based polymers and high-performance additives to improve durability and thermal resistance. Thermoset materials are evolving with novel curing agents and nano-reinforcements, enabling superior mechanical properties and recyclability through chemical recycling techniques. Advances in hybrid materials combining thermoplastic and thermoset properties are paving the way for multifunctional applications in automotive, aerospace, and electronics industries.

Crosslinking density

Thermoset polymers exhibit high crosslinking density, resulting in enhanced mechanical strength and thermal resistance compared to the low crosslinking density and greater flexibility of thermoplastic polymers.

Glass transition temperature (Tg)

Thermoplastics typically exhibit a distinct glass transition temperature (Tg) where they soften and become malleable, while thermosets do not have a clear Tg due to their cross-linked molecular structure that remains rigid and heat resistant.

Melt viscosity

Thermoplastics exhibit lower melt viscosity allowing easier flow and reshaping upon heating, whereas thermosets have higher melt viscosity due to rigid cross-linked structures preventing flow and reprocessing after curing.

Chain scission

Thermoplastics undergo reversible chain scission allowing reshaping upon heating, while thermosets experience irreversible chain scission leading to permanent crosslinked networks and thermal stability.

Amorphous vs. crystalline phases

Thermoplastics typically exhibit both amorphous and crystalline phases with reversible melting behavior, while thermosets primarily consist of crosslinked amorphous networks that do not melt but decompose upon heating.

Heat deflection temperature (HDT)

Thermoset polymers generally exhibit higher Heat Deflection Temperature (HDT) than thermoplastics due to their cross-linked molecular structure.

Injection molding

Thermoplastic materials, which soften when heated and can be reshaped multiple times, are ideal for injection molding processes requiring rapid production and recyclability, while thermoset polymers, which harden irreversibly after curing, offer superior heat resistance and mechanical strength but require longer cycle times and cannot be remelted or reshaped.

Curing reaction

Thermoplastics undergo physical changes without chemical curing, while thermosets require a chemical curing reaction to form irreversible cross-linked networks.

Recyclability

Thermoplastics are highly recyclable due to their ability to be remelted and reshaped multiple times, whereas thermosets are difficult to recycle because their cross-linked structure prevents remelting.

Post-processing modification

Thermoplastics allow easy post-processing modification through reheating and reshaping, whereas thermosets undergo irreversible curing that prevents reshaping or extensive post-processing adjustments.

Thermoplastic vs Thermoset Infographic

njnir.com

njnir.com