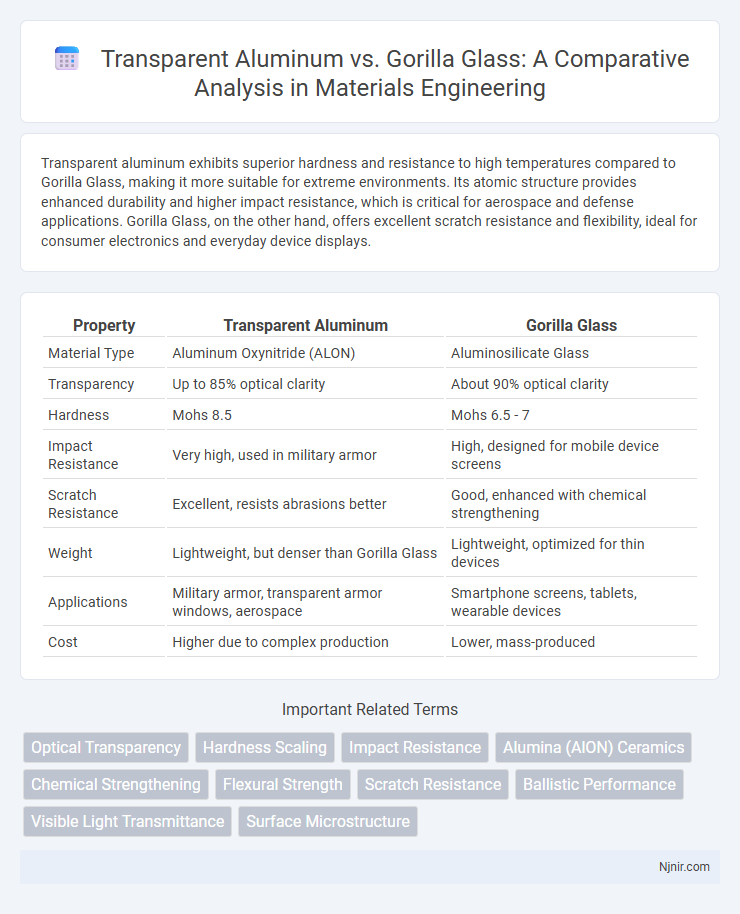

Transparent aluminum exhibits superior hardness and resistance to high temperatures compared to Gorilla Glass, making it more suitable for extreme environments. Its atomic structure provides enhanced durability and higher impact resistance, which is critical for aerospace and defense applications. Gorilla Glass, on the other hand, offers excellent scratch resistance and flexibility, ideal for consumer electronics and everyday device displays.

Table of Comparison

| Property | Transparent Aluminum | Gorilla Glass |

|---|---|---|

| Material Type | Aluminum Oxynitride (ALON) | Aluminosilicate Glass |

| Transparency | Up to 85% optical clarity | About 90% optical clarity |

| Hardness | Mohs 8.5 | Mohs 6.5 - 7 |

| Impact Resistance | Very high, used in military armor | High, designed for mobile device screens |

| Scratch Resistance | Excellent, resists abrasions better | Good, enhanced with chemical strengthening |

| Weight | Lightweight, but denser than Gorilla Glass | Lightweight, optimized for thin devices |

| Applications | Military armor, transparent armor windows, aerospace | Smartphone screens, tablets, wearable devices |

| Cost | Higher due to complex production | Lower, mass-produced |

Introduction to Transparent Aluminum and Gorilla Glass

Transparent Aluminum, scientifically known as aluminum oxynitride (ALON), is a durable ceramic compound offering exceptional strength and clarity, making it ideal for military and aerospace applications. Gorilla Glass, developed by Corning, is a chemically strengthened glass optimized for consumer electronics, providing high scratch resistance and thin-profile durability. Both materials prioritize transparency and toughness but serve distinct market needs based on composition and performance characteristics.

Composition and Material Structure Comparison

Transparent aluminum, primarily aluminum oxynitride (AlON), features a crystalline polycrystalline structure combining aluminum, oxygen, and nitrogen atoms, offering high hardness and excellent optical clarity. Gorilla Glass, a chemically strengthened aluminosilicate glass, contains a network of silicon dioxide with added metal oxides, providing enhanced scratch resistance and flexibility due to its amorphous structure. The crystalline lattice of transparent aluminum results in superior impact resistance and durability compared to the more brittle, yet lightweight, amorphous composition of Gorilla Glass.

Optical Transparency and Clarity

Transparent aluminum, a ceramic aluminum oxynitride (AlON), offers superior optical transparency in the visible and near-infrared spectrum, with transmittance rates up to 85%. Gorilla Glass, a chemically strengthened aluminosilicate glass, provides excellent clarity with high light transmission around 90%, but it is more prone to surface scratches than transparent aluminum. Transparent aluminum's greater hardness and durability combined with its optical clarity make it ideal for applications requiring both robust protection and minimal visual distortion.

Mechanical Strength and Durability

Transparent aluminum, known chemically as aluminum oxynitride (ALON), exhibits superior mechanical strength with a Mohs hardness of 8.5 and a high fracture toughness, making it highly resistant to scratching and impacts compared to Gorilla Glass, which typically rates around 6.5-7 on the Mohs scale. ALON also surpasses Gorilla Glass in durability due to its exceptional resistance to pressure and thermal shock, maintaining structural integrity under extreme conditions. These properties make transparent aluminum ideal for applications requiring robust, long-lasting transparent armor and protective windows.

Impact Resistance and Toughness

Transparent aluminum exhibits superior impact resistance compared to Gorilla Glass due to its ceramic compound structure, enabling it to withstand higher force without cracking. Gorilla Glass, primarily composed of aluminosilicate, offers excellent toughness with a balance between hardness and flexibility but is more prone to shattering under extreme impact. The enhanced toughness of transparent aluminum makes it an ideal material for applications requiring extreme durability, such as military armor and aerospace windows.

Thermal Stability and Environmental Performance

Transparent aluminum exhibits superior thermal stability compared to Gorilla Glass, maintaining its structural integrity at temperatures exceeding 1000degC, while Gorilla Glass typically withstands up to 600degC before degradation. Environmentally, transparent aluminum offers enhanced resistance to chemical corrosion and UV radiation, resulting in longer lifespan and reduced maintenance. In contrast, Gorilla Glass, though durable, is more susceptible to thermal stress and surface scratches, impacting its environmental performance over time.

Manufacturing Processes and Scalability

Transparent aluminum is produced through advanced sputtering techniques and atomic layer deposition, enabling a durable ceramic-like film with exceptional hardness and resistance. Gorilla Glass is manufactured using an ion-exchange process that strengthens aluminosilicate glass, offering high impact resistance and flexibility for consumer electronics. Scalability of Gorilla Glass is well-established with mass production capabilities, while transparent aluminum faces challenges in large-scale manufacturing due to complex deposition methods and higher production costs.

Applications in Modern Technology

Transparent aluminum, known scientifically as aluminum oxynitride (ALON), is prized in defense and aerospace for its exceptional hardness, optical clarity, and resistance to high-velocity impacts, making it ideal for bulletproof windows and sensor domes. Gorilla Glass, a chemically strengthened aluminosilicate glass by Corning, dominates consumer electronics with its lightweight, scratch resistance, and enhanced durability, primarily used in smartphones, tablets, and wearables. While transparent aluminum offers superior strength and thermal stability for military and industrial applications, Gorilla Glass provides optimal cost-effectiveness and surface protection for everyday electronic devices.

Cost Analysis and Market Availability

Transparent aluminum offers higher durability and scratch resistance compared to Gorilla Glass but comes at a significantly higher production cost due to complex manufacturing processes involving aluminum oxynitride. Gorilla Glass remains more widely available and affordable, dominating the consumer electronics market with its established supply chains and cost-efficient production methods. While transparent aluminum serves niche applications requiring extreme strength, Gorilla Glass provides a cost-effective solution for mass-market devices.

Future Prospects in Advanced Materials Engineering

Transparent Aluminum exhibits promising potential in advanced materials engineering due to its exceptional strength, thermal resistance, and optical clarity, positioning it as a superior alternative for aerospace and military applications. Gorilla Glass, while widely popular in consumer electronics for its scratch resistance and durability, faces limitations in extreme environments, driving research towards integrating ceramic-metal composites like Transparent Aluminum for enhanced performance. Ongoing advancements in nanostructuring and hybrid material synthesis indicate that Transparent Aluminum could redefine future transparent armor and display technologies with unmatched robustness and versatility.

Optical Transparency

Transparent Aluminum and Gorilla Glass both offer high optical transparency, with Gorilla Glass providing superior clarity and scratch resistance ideal for touchscreens, while Transparent Aluminum excels in maintaining visibility under extreme durability and impact conditions.

Hardness Scaling

Transparent aluminum exhibits higher hardness scaling with superior scratch resistance compared to Gorilla Glass, making it more durable for advanced protective applications.

Impact Resistance

Transparent aluminum offers significantly higher impact resistance than Gorilla Glass, making it more durable for extreme conditions and military applications.

Alumina (AlON) Ceramics

Alumina (AlON) ceramics in transparent aluminum provide superior hardness, impact resistance, and optical clarity compared to Gorilla Glass, making them ideal for advanced protective applications.

Chemical Strengthening

Chemical strengthening enhances the durability of both transparent aluminum and Gorilla Glass by ion-exchanging surface layers, with transparent aluminum offering superior resistance to scratches and impacts due to its crystalline structure.

Flexural Strength

Transparent aluminum demonstrates higher flexural strength than Gorilla Glass, making it more resistant to bending and structural deformation under stress.

Scratch Resistance

Transparent Aluminum offers significantly higher scratch resistance than Gorilla Glass, making it more durable for applications requiring enhanced surface protection.

Ballistic Performance

Transparent aluminum exhibits superior ballistic performance compared to Gorilla Glass, offering enhanced resistance to high-velocity impacts and greater durability in protective applications.

Visible Light Transmittance

Transparent Aluminum exhibits a visible light transmittance of approximately 90%, surpassing Gorilla Glass, which typically transmits around 85% of visible light.

Surface Microstructure

Transparent Aluminum features a crystalline microstructure that enhances scratch resistance and impact durability, whereas Gorilla Glass employs an ion-exchange surface treatment creating a compressive stress layer to improve toughness and surface hardness.

Transparent Aluminum vs Gorilla Glass Infographic

njnir.com

njnir.com