Self-healing polymers autonomously repair damage through molecular mechanisms, extending material lifespan and reducing maintenance costs. Self-cleaning coatings, on the other hand, utilize surface properties such as hydrophobicity or photocatalytic activity to repel contaminants and maintain cleanliness. Both technologies enhance durability but address different challenges: structural integrity versus surface contamination.

Table of Comparison

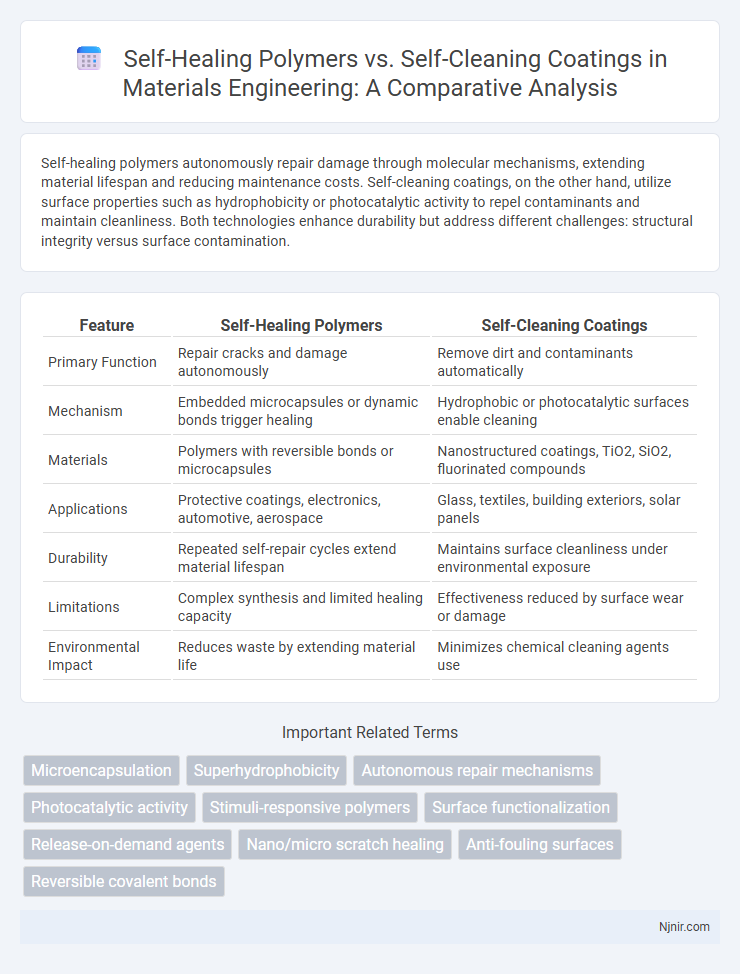

| Feature | Self-Healing Polymers | Self-Cleaning Coatings |

|---|---|---|

| Primary Function | Repair cracks and damage autonomously | Remove dirt and contaminants automatically |

| Mechanism | Embedded microcapsules or dynamic bonds trigger healing | Hydrophobic or photocatalytic surfaces enable cleaning |

| Materials | Polymers with reversible bonds or microcapsules | Nanostructured coatings, TiO2, SiO2, fluorinated compounds |

| Applications | Protective coatings, electronics, automotive, aerospace | Glass, textiles, building exteriors, solar panels |

| Durability | Repeated self-repair cycles extend material lifespan | Maintains surface cleanliness under environmental exposure |

| Limitations | Complex synthesis and limited healing capacity | Effectiveness reduced by surface wear or damage |

| Environmental Impact | Reduces waste by extending material life | Minimizes chemical cleaning agents use |

Introduction to Smart Materials in Modern Engineering

Self-healing polymers are innovative materials capable of autonomously repairing damage, enhancing durability and lifespan in engineering applications, while self-cleaning coatings prevent surface contamination through advanced hydrophobic or photocatalytic properties. Both types represent pivotal advancements in smart materials, enabling responsive and adaptive functionalities in sectors such as aerospace, automotive, and construction. Integration of these materials improves system reliability and reduces maintenance costs, driving efficiency in modern engineering solutions.

Fundamental Concepts: Self-Healing Polymers vs Self-Cleaning Coatings

Self-healing polymers possess intrinsic or extrinsic mechanisms that allow them to autonomously repair damages, restoring mechanical integrity and functionality through chemical reactions or embedded healing agents. Self-cleaning coatings rely primarily on surface properties such as superhydrophobicity or photocatalytic activity, which repel contaminants or degrade organic matter to maintain cleanliness. The fundamental distinction lies in self-healing polymers actively reversing structural damage, whereas self-cleaning coatings primarily prevent surface fouling through physical or chemical surface modifications.

Mechanisms of Self-Healing in Polymers

Self-healing polymers restore their integrity through mechanisms such as microcapsule rupture, reversible covalent bonding, and supramolecular interactions, enabling the repair of cracks and damage autonomously. These mechanisms differ fundamentally from self-cleaning coatings, which rely on photocatalytic activity or superhydrophobic surfaces to repel contaminants without repairing physical damage. Advances in dynamic covalent chemistry and shape-memory effects have significantly enhanced the efficiency and repeatability of self-healing processes in polymeric materials.

Technologies Behind Self-Cleaning Coatings

Self-cleaning coatings utilize photocatalytic materials like titanium dioxide (TiO2) to break down organic contaminants through light-induced chemical reactions, enabling surface cleanliness without manual intervention. These coatings incorporate nanostructured surfaces that reduce adhesion of dirt and water, promoting the easy removal of particles by rain or air flow. Advanced formulations often combine hydrophobic and photocatalytic properties, maximizing durability and efficiency in environments ranging from building exteriors to solar panels.

Comparative Performance in Durability and Longevity

Self-healing polymers exhibit superior durability by autonomously repairing micro-cracks, significantly extending material lifespan and reducing maintenance frequency. In contrast, self-cleaning coatings primarily maintain surface cleanliness and resist fouling but offer limited repair capabilities, making them less effective in addressing physical degradation over time. The longevity of self-healing polymers often surpasses that of self-cleaning coatings in harsh or mechanically demanding environments due to their intrinsic restorative properties.

Application Fields: Where Each Solution Excels

Self-healing polymers excel in applications requiring durability and extended lifecycle, such as automotive parts, aerospace components, and consumer electronics, where damage repair is crucial to performance and safety. Self-cleaning coatings are ideal for architectural glass, solar panels, and medical equipment surfaces, enhancing functionality by reducing maintenance and preventing contamination. Each solution optimizes performance based on specific field demands--self-healing polymers prioritize mechanical resilience, while self-cleaning coatings focus on surface hygiene and transparency.

Material Selection Criteria for Engineering Projects

Material selection for self-healing polymers centers on their ability to autonomously repair mechanical damage through reversible chemical bonds or embedded healing agents, requiring high elasticity, compatibility with the matrix, and environmental stability. In contrast, self-cleaning coatings prioritize hydrophobicity or photocatalytic properties, chemical resistance, and durability under UV exposure to maintain surface cleanliness. Engineering projects must evaluate application conditions such as mechanical stress, exposure to contaminants or weather, reusability, and maintenance demands to select materials that optimize performance and longevity.

Environmental Impact and Sustainability Considerations

Self-healing polymers reduce waste by extending the lifespan of materials through autonomous repair mechanisms, minimizing the need for replacements and lowering resource consumption. Self-cleaning coatings enhance sustainability by decreasing the use of water and chemical cleaners in maintenance, contributing to reduced environmental pollution. Both technologies promote eco-friendly practices, but self-healing polymers address material longevity while self-cleaning coatings primarily focus on reducing maintenance-related environmental impact.

Current Challenges and Limitations in Practical Use

Self-healing polymers face challenges in achieving rapid and complete repair under diverse environmental conditions, often limited by the complexity of triggering mechanisms and material fatigue over repeated cycles. Self-cleaning coatings struggle with durability issues, as their surface properties can degrade due to abrasion, UV exposure, and chemical contaminants, reducing long-term effectiveness. Both technologies encounter scalability and cost barriers, hindering widespread adoption in industrial and consumer applications.

Future Prospects and Innovations in Smart Materials

Self-healing polymers are advancing with innovations in microcapsule embedding and dynamic covalent bonds, enhancing autonomous repair capabilities and extending material lifespan in industries such as aerospace and electronics. Self-cleaning coatings are evolving through nanoscale surface engineering and photocatalytic materials, offering resistance to contamination and reducing maintenance in construction and automotive sectors. Future prospects in smart materials emphasize integrating self-healing and self-cleaning functionalities to create multifunctional surfaces that improve durability, sustainability, and efficiency across various applications.

Microencapsulation

Microencapsulation enhances self-healing polymers by enabling targeted release of healing agents, while in self-cleaning coatings, it facilitates controlled delivery of active substances to maintain surface cleanliness.

Superhydrophobicity

Self-healing polymers restore structural integrity through intrinsic repair mechanisms while self-cleaning coatings utilize superhydrophobicity to repel water and contaminants, enhancing surface durability and cleanliness.

Autonomous repair mechanisms

Self-healing polymers utilize intrinsic or extrinsic autonomous repair mechanisms to restore material integrity after damage, whereas self-cleaning coatings primarily rely on surface properties to repel contaminants without active repair functions.

Photocatalytic activity

Self-healing polymers exhibit intrinsic repair mechanisms through reversible chemical bonds, whereas self-cleaning coatings primarily rely on photocatalytic activity, such as titanium dioxide (TiO2), to degrade organic contaminants under UV light.

Stimuli-responsive polymers

Stimuli-responsive polymers in self-healing materials enable autonomous damage repair by reacting to environmental triggers, whereas in self-cleaning coatings, these polymers facilitate surface cleanliness through stimuli-induced changes in wettability or adhesion.

Surface functionalization

Surface functionalization enhances self-healing polymers by enabling dynamic bond reformation for damage repair, while it imparts self-cleaning coatings with hydrophobic or photocatalytic properties to repel contaminants and degrade organic matter.

Release-on-demand agents

Release-on-demand agents in self-healing polymers enable targeted repair by activating healing mechanisms upon damage, whereas in self-cleaning coatings they trigger surface renewal processes to remove contaminants efficiently.

Nano/micro scratch healing

Self-healing polymers utilize nano/micro-scale mechanisms to autonomously repair scratches and restore structural integrity, whereas self-cleaning coatings primarily repel contaminants without addressing micro-level surface damage.

Anti-fouling surfaces

Self-healing polymers enhance anti-fouling surfaces by autonomously repairing damage to maintain functionality, while self-cleaning coatings prevent fouling through surface properties that repel contaminants and facilitate debris removal.

Reversible covalent bonds

Self-healing polymers utilize reversible covalent bonds to enable molecular reconfiguration and autonomous repair, whereas self-cleaning coatings primarily rely on surface chemistry modifications without reversible covalent bond mechanisms.

Self-healing polymers vs Self-cleaning coatings Infographic

njnir.com

njnir.com