Liquid Crystal Polymers (LCPs) exhibit exceptional dimensional stability and chemical resistance due to their highly ordered molecular structure, making them ideal for high-performance electronic components. Polyimides offer superior thermal stability and flexibility, which are crucial for applications requiring wide temperature ranges and mechanical durability. Comparing LCPs and Polyimides highlights trade-offs between rigidity and thermal endurance, guiding material selection in advanced engineering projects.

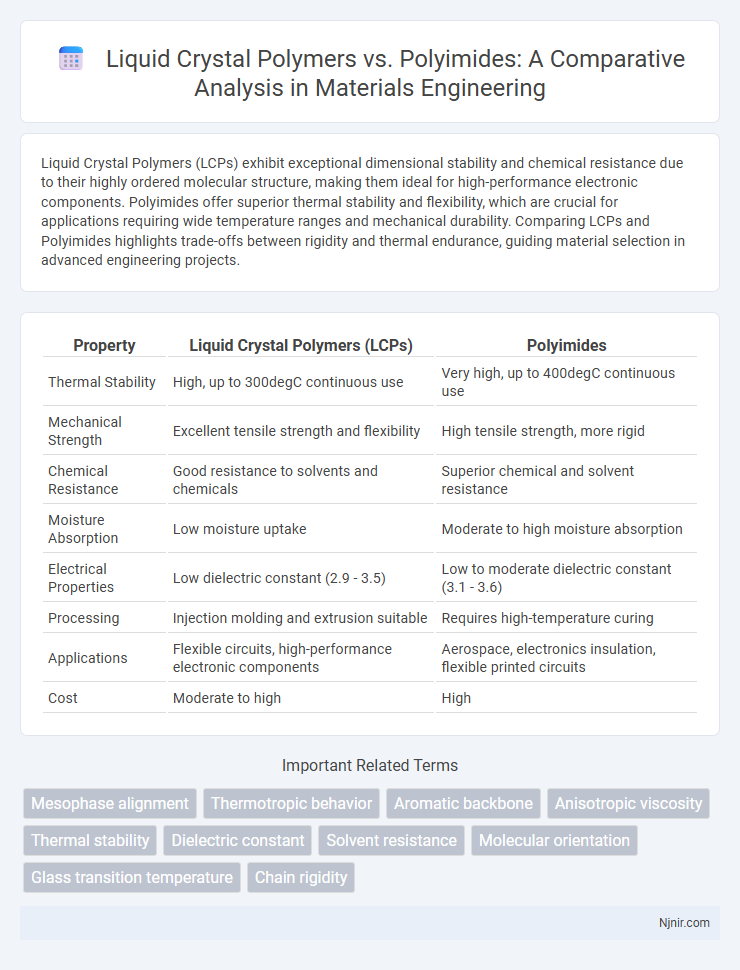

Table of Comparison

| Property | Liquid Crystal Polymers (LCPs) | Polyimides |

|---|---|---|

| Thermal Stability | High, up to 300degC continuous use | Very high, up to 400degC continuous use |

| Mechanical Strength | Excellent tensile strength and flexibility | High tensile strength, more rigid |

| Chemical Resistance | Good resistance to solvents and chemicals | Superior chemical and solvent resistance |

| Moisture Absorption | Low moisture uptake | Moderate to high moisture absorption |

| Electrical Properties | Low dielectric constant (2.9 - 3.5) | Low to moderate dielectric constant (3.1 - 3.6) |

| Processing | Injection molding and extrusion suitable | Requires high-temperature curing |

| Applications | Flexible circuits, high-performance electronic components | Aerospace, electronics insulation, flexible printed circuits |

| Cost | Moderate to high | High |

Introduction to Liquid Crystal Polymers and Polyimides

Liquid Crystal Polymers (LCPs) are advanced polymers characterized by their highly ordered molecular structure that imparts exceptional thermal stability, chemical resistance, and mechanical strength, making them ideal for high-performance electronic and aerospace applications. Polyimides are a class of heat-resistant polymers known for their excellent thermal stability, dielectric properties, and mechanical robustness, widely used in flexible electronics, insulation, and aerospace components. Both LCPs and polyimides serve as critical materials in environments demanding high durability and thermal endurance, with LCPs offering liquid crystalline behavior and polyimides providing superior thermal and chemical resistance.

Chemical Structures and Molecular Architectures

Liquid Crystal Polymers (LCPs) possess rigid, rod-like molecular structures with highly ordered mesogenic units that promote anisotropic properties and enhance mechanical strength. Polyimides feature aromatic imide rings within their backbone, providing thermal stability and excellent chemical resistance due to their rigid, planar molecular architecture. The distinct differences in chain flexibility and molecular alignment between LCPs and polyimides result in varied applications, with LCPs excelling in high-performance composites and polyimides favored for high-temperature insulation and electronics.

Thermal Stability and Heat Resistance

Liquid Crystal Polymers (LCPs) exhibit exceptional thermal stability due to their highly ordered molecular structure, enabling continuous use at temperatures up to 260degC with minimal degradation. Polyimides offer superior heat resistance, maintaining mechanical properties and dimensional stability in extreme environments exceeding 300degC, making them ideal for aerospace and electronics applications. The choice between LCPs and polyimides depends on specific thermal requirements, with LCPs favored for moderate high-temperature use and polyimides preferred for ultra-high temperature stability.

Mechanical Properties and Performance

Liquid Crystal Polymers (LCPs) exhibit exceptional mechanical properties, including high tensile strength, stiffness, and dimensional stability at elevated temperatures, outperforming many conventional polymers such as Polyimides. Polyimides offer superior thermal stability and chemical resistance but generally have lower mechanical strength and toughness compared to LCPs. The high crystallinity and molecular orientation in LCPs contribute to their outstanding fatigue resistance and impact strength, making them ideal for demanding mechanical performance in aerospace and electronics applications.

Electrical and Dielectric Characteristics

Liquid Crystal Polymers (LCPs) exhibit superior electrical insulation and low dielectric constant, typically around 3.0 to 3.2, making them ideal for high-frequency applications and minimizing signal loss in electronic devices. Polyimides offer excellent thermal stability and a dielectric constant ranging from 3.4 to 3.6, supporting reliable performance in harsh environments with moderate electrical insulation properties. LCPs outperform polyimides in moisture resistance and dielectric strength, providing enhanced durability for flexible circuits and microelectronic packaging.

Processing Techniques and Fabrication Methods

Liquid Crystal Polymers (LCPs) are processed primarily through injection molding and extrusion due to their excellent flow properties and thermal stability, enabling precise micro-scale feature fabrication. Polyimides, known for their high thermal resistance and mechanical strength, are typically fabricated using solution casting, spin coating, or vapor deposition techniques to form thin films suitable for flexible electronics and aerospace applications. The choice between LCPs and polyimides hinges on the specific processing method compatibility with desired product geometry, thermal budget, and mechanical requirements.

Comparison of Chemical Resistance

Liquid Crystal Polymers (LCPs) display superior chemical resistance compared to Polyimides, particularly against strong acids, bases, and organic solvents, making them ideal for harsh chemical environments. Polyimides, while resistant to high temperatures and exhibit good mechanical properties, tend to degrade or lose integrity under prolonged exposure to aggressive chemicals such as concentrated alkalis or oxidizers. The inherent molecular structure of LCPs, characterized by rigid rod-like chains and high crystallinity, contributes to their enhanced barrier properties and resistance to chemical attack relative to the more amorphous and thermally sensitive Polyimides.

Applications in Advanced Engineering Fields

Liquid Crystal Polymers (LCPs) exhibit exceptional dimensional stability and chemical resistance, making them ideal for precision components in aerospace and electronics, such as connector housings and flexible printed circuits. Polyimides offer superior thermal stability and mechanical strength, essential for use in high-temperature environments like microelectronics insulation and aerospace composites. Both materials enable lightweight, durable solutions, but LCPs excel in electrical applications while polyimides dominate in thermal and structural roles within advanced engineering.

Environmental Impact and Sustainability

Liquid Crystal Polymers (LCPs) exhibit superior chemical resistance and recyclability compared to conventional Polyimides, reducing environmental waste and promoting sustainability in high-performance applications. Polyimides, while known for thermal stability, often involve energy-intensive synthesis and pose challenges in biodegradation, leading to increased ecological footprint. The adoption of LCPs in electronics and aerospace sectors accelerates eco-friendly manufacturing by lowering emissions and enhancing material lifecycle efficiency.

Future Trends and Innovations in Material Development

Liquid Crystal Polymers (LCPs) and Polyimides continue to evolve with innovations targeting enhanced thermal stability, mechanical strength, and electrical performance for advanced electronics and aerospace applications. Emerging trends highlight the integration of nanomaterials and hybrid composites to improve flexibility and durability while maintaining superior chemical resistance. Future material development emphasizes sustainable production processes and recyclability to meet environmental regulations and industry demands.

Mesophase alignment

Liquid Crystal Polymers exhibit superior mesophase alignment compared to polyimides, enabling enhanced anisotropic mechanical and thermal properties essential for advanced electronic applications.

Thermotropic behavior

Liquid Crystal Polymers exhibit superior thermotropic behavior with precise molecular alignment and high thermal stability compared to the more amorphous and less thermally stable nature of Polyimides.

Aromatic backbone

Liquid Crystal Polymers with rigid aromatic backbones offer superior thermal stability and mechanical strength compared to the more flexible aromatic backbone structure of polyimides.

Anisotropic viscosity

Liquid Crystal Polymers exhibit highly anisotropic viscosity due to their ordered molecular alignment, whereas Polyimides display more isotropic viscosity characteristics stemming from their amorphous polymer structure.

Thermal stability

Liquid Crystal Polymers exhibit superior thermal stability with melting points above 300degC, making them more resistant to degradation compared to Polyimides, which typically withstand continuous use temperatures up to 250-300degC.

Dielectric constant

Liquid Crystal Polymers exhibit a lower dielectric constant, typically around 2.9 to 3.2, compared to Polyimides, which usually range from 3.4 to 3.9, making LCPs more suitable for high-frequency electronic applications requiring reduced signal loss.

Solvent resistance

Liquid Crystal Polymers exhibit superior solvent resistance compared to Polyimides, making them more suitable for harsh chemical environments in advanced manufacturing.

Molecular orientation

Liquid Crystal Polymers exhibit highly ordered molecular orientation resulting in superior thermal stability and mechanical strength compared to the less oriented, amorphous molecular structure of Polyimides.

Glass transition temperature

Liquid Crystal Polymers exhibit higher glass transition temperatures (typically above 280degC) compared to Polyimides, which generally have glass transition temperatures ranging from 200degC to 300degC depending on their specific chemical structure.

Chain rigidity

Liquid Crystal Polymers exhibit higher chain rigidity than Polyimides, resulting in superior mechanical strength and thermal stability in advanced engineering applications.

Liquid Crystal Polymers vs Polyimides Infographic

njnir.com

njnir.com