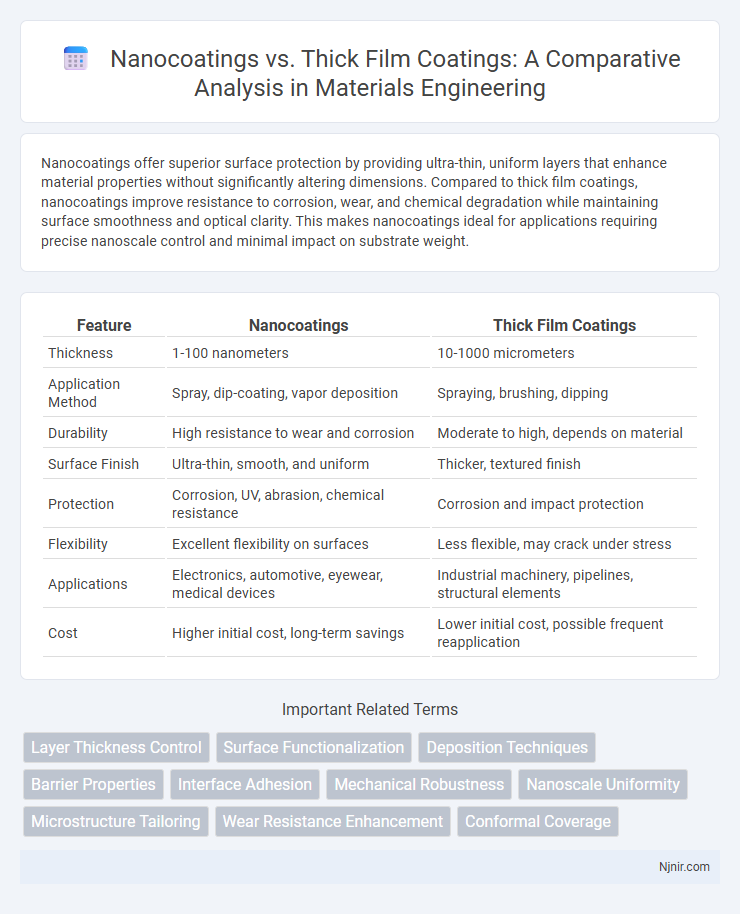

Nanocoatings offer superior surface protection by providing ultra-thin, uniform layers that enhance material properties without significantly altering dimensions. Compared to thick film coatings, nanocoatings improve resistance to corrosion, wear, and chemical degradation while maintaining surface smoothness and optical clarity. This makes nanocoatings ideal for applications requiring precise nanoscale control and minimal impact on substrate weight.

Table of Comparison

| Feature | Nanocoatings | Thick Film Coatings |

|---|---|---|

| Thickness | 1-100 nanometers | 10-1000 micrometers |

| Application Method | Spray, dip-coating, vapor deposition | Spraying, brushing, dipping |

| Durability | High resistance to wear and corrosion | Moderate to high, depends on material |

| Surface Finish | Ultra-thin, smooth, and uniform | Thicker, textured finish |

| Protection | Corrosion, UV, abrasion, chemical resistance | Corrosion and impact protection |

| Flexibility | Excellent flexibility on surfaces | Less flexible, may crack under stress |

| Applications | Electronics, automotive, eyewear, medical devices | Industrial machinery, pipelines, structural elements |

| Cost | Higher initial cost, long-term savings | Lower initial cost, possible frequent reapplication |

Introduction to Nanocoatings and Thick Film Coatings

Nanocoatings consist of ultra-thin layers measured in nanometers, designed to enhance surface properties such as hydrophobicity, corrosion resistance, and antimicrobial effects without altering the substrate's weight or dimensions. Thick film coatings are substantially thicker, typically ranging from micrometers to millimeters, providing robust protection, thermal insulation, and mechanical durability for industrial applications. The distinct thickness and application methods of nanocoatings versus thick film coatings result in differing performance benefits tailored to specific environmental and functional requirements.

Fundamental Differences in Coating Thickness

Nanocoatings typically range from a few nanometers to several micrometers in thickness, offering ultra-thin, transparent layers that enhance surface properties without altering the substrate's dimensions. In contrast, thick film coatings generally measure tens to hundreds of micrometers, providing robust protection and mechanical strength but significantly increasing the coated surface's thickness. The fundamental difference lies in nanocoatings enabling precise, minimal thickness applications for functional enhancements, whereas thick film coatings prioritize durability and structural reinforcement through considerably greater coating thickness.

Material Composition and Structure

Nanocoatings consist of ultra-thin layers, often nanometers thick, composed of materials such as metal oxides, polymers, or hybrid organic-inorganic compounds that form uniform, tightly packed molecular structures. Thick film coatings typically use ceramic, polymer, or composite materials in micron-scale layers, featuring heterogeneous microstructures with granular or particulate phases. The atomic-scale uniformity in nanocoatings enhances surface properties like hydrophobicity and barrier resistance, while thick films provide mechanical strength and durability through their bulk architecture.

Surface Properties and Functionalities

Nanocoatings provide ultra-thin layers, typically in the nanometer range, that enhance surface properties such as hydrophobicity, anti-corrosion, and antimicrobial effects without significantly altering the substrate's dimensions. Thick film coatings, often ranging from micrometers to millimeters in thickness, offer robust mechanical protection and improved thermal or electrical insulation but may affect the surface texture and weight more substantially. The choice between nanocoatings and thick film coatings depends on the required surface functionality, with nanocoatings excelling in preserving surface smoothness and enhancing chemical resistance, while thick films deliver structural durability and targeted performance.

Application Methods and Techniques

Nanocoatings are typically applied using advanced techniques such as chemical vapor deposition (CVD), atomic layer deposition (ALD), or spray coating, allowing for ultra-thin, uniform layers with precise control at the nanoscale. Thick film coatings generally utilize methods like screen printing, dip coating, or thermal spraying, which build up layers in the micrometer to millimeter range suitable for heavy-duty protection or insulation. The choice of application method directly influences the coating's thickness, adhesion, and functional properties tailored to industrial, automotive, or electronic applications.

Performance in Corrosion and Wear Protection

Nanocoatings provide superior corrosion resistance and wear protection due to their ultra-thin, uniform layers that penetrate microscopic surface irregularities, enhancing barrier properties without adding bulk. Thick film coatings offer robust mechanical protection but can suffer from cracking and reduced adhesion under stress, compromising long-term durability. Advanced nanocoatings demonstrate higher performance in harsh environments by maintaining flexibility and chemical stability, extending the lifespan of treated materials significantly.

Optical and Electrical Properties

Nanocoatings exhibit superior optical clarity and enhanced electrical conductivity compared to thick film coatings due to their ultra-thin, uniform layers that minimize light scattering and resistivity. Thick film coatings often suffer from increased surface roughness and thickness variations, leading to reduced transparency and higher electrical resistance. Nanocoatings enable precise tuning of refractive indices and electrical parameters, making them ideal for applications in photovoltaics and transparent electronics.

Industry Applications and Use Cases

Nanocoatings provide advanced surface protection in industries like electronics, aerospace, and automotive due to their ultra-thin, durable layers that resist corrosion, wear, and contaminants. Thick film coatings are favored in heavy industrial applications such as machinery and infrastructure maintenance, offering robust thermal and chemical resistance where thicker barriers are essential. Both technologies enhance product lifespan and performance, with nanocoatings optimizing precision and weight-sensitive components while thick film coatings support structural durability and heavy-duty protection.

Cost Analysis and Scalability

Nanocoatings typically offer lower material and application costs due to their minimal thickness, reducing raw material consumption and energy use during deposition, making them economically advantageous for large-scale production. Thick film coatings, while providing enhanced durability and barrier properties, incur higher expenses in both materials and labor, often requiring more complex application equipment and longer curing times, which can limit scalability. Companies must weigh the cost-effectiveness of nanocoatings for high-volume, cost-sensitive markets against the superior performance but increased cost of thick film coatings in specialized, lower-volume applications.

Future Trends in Coating Technologies

Nanocoatings offer enhanced surface properties with ultra-thin layers, promoting durability, corrosion resistance, and self-cleaning features that outperform thicker traditional coatings. Future trends emphasize integrating nanomaterials like graphene and nanoparticles to improve thermal stability and antimicrobial efficacy while reducing environmental impact. Advances in smart coatings will enable responsive functionalities such as color change, conductivity modulation, and damage healing, making nanocoatings pivotal in next-generation industrial and biomedical applications.

Layer Thickness Control

Nanocoatings provide precise layer thickness control at the nanoscale, enabling enhanced surface properties, while thick film coatings offer less uniformity and higher variability in thickness.

Surface Functionalization

Nanocoatings provide superior surface functionalization by creating ultra-thin, uniform layers that enhance properties like hydrophobicity, corrosion resistance, and biocompatibility, whereas thick film coatings primarily offer mechanical protection with less precision in surface property modification.

Deposition Techniques

Nanocoatings utilize advanced techniques such as atomic layer deposition (ALD) and chemical vapor deposition (CVD) for precise, ultra-thin layering, whereas thick film coatings primarily rely on spray coating, dip coating, and thermal spray methods for thicker, more durable applications.

Barrier Properties

Nanocoatings provide superior barrier properties by forming ultrathin, highly uniform layers that effectively block moisture, gases, and contaminants compared to thicker film coatings that rely on bulk material thickness for protection.

Interface Adhesion

Nanocoatings exhibit superior interface adhesion compared to thick film coatings due to their molecular-scale thickness and enhanced surface energy interactions, resulting in improved durability and resistance to delamination.

Mechanical Robustness

Nanocoatings offer superior mechanical robustness compared to thick film coatings due to their enhanced adhesion, flexibility, and resistance to abrasion and impact.

Nanoscale Uniformity

Nanocoatings provide superior nanoscale uniformity compared to thick film coatings, ensuring enhanced surface smoothness and consistent protective properties at the molecular level.

Microstructure Tailoring

Nanocoatings enable precise microstructure tailoring at the nanoscale for enhanced surface properties, whereas thick film coatings modify microstructure on a bulk scale, impacting overall material performance.

Wear Resistance Enhancement

Nanocoatings enhance wear resistance by providing ultra-thin, hard, and uniform protective layers that reduce friction and surface degradation more effectively than conventional thick film coatings.

Conformal Coverage

Nanocoatings provide superior conformal coverage by uniformly adhering to complex surfaces at the nanoscale, whereas thick film coatings often struggle to achieve consistent coverage on intricate geometries.

nanocoatings vs thick film coatings Infographic

njnir.com

njnir.com