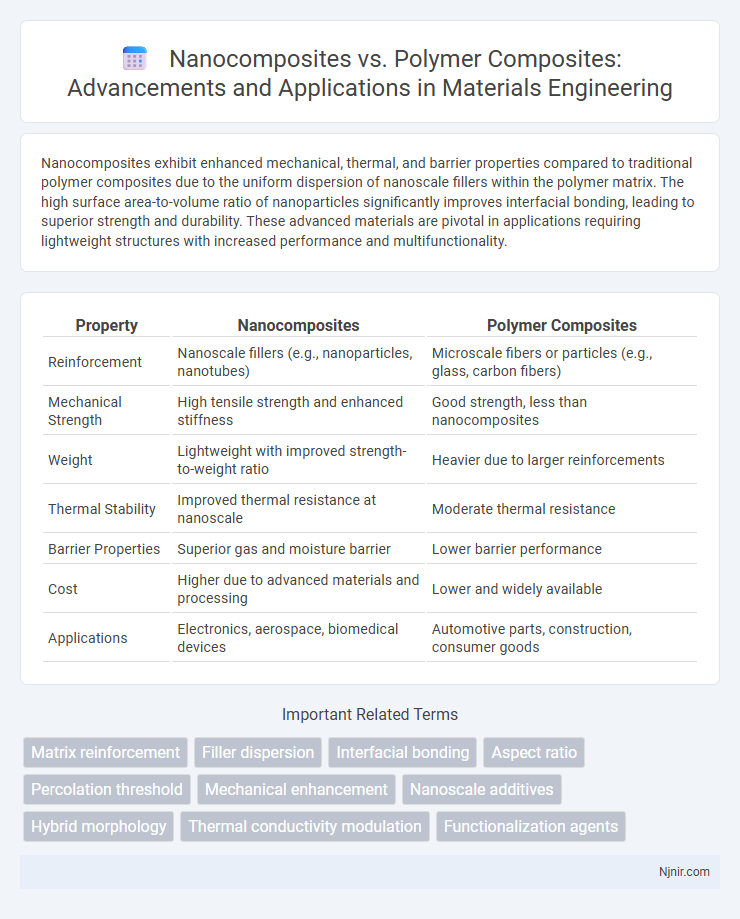

Nanocomposites exhibit enhanced mechanical, thermal, and barrier properties compared to traditional polymer composites due to the uniform dispersion of nanoscale fillers within the polymer matrix. The high surface area-to-volume ratio of nanoparticles significantly improves interfacial bonding, leading to superior strength and durability. These advanced materials are pivotal in applications requiring lightweight structures with increased performance and multifunctionality.

Table of Comparison

| Property | Nanocomposites | Polymer Composites |

|---|---|---|

| Reinforcement | Nanoscale fillers (e.g., nanoparticles, nanotubes) | Microscale fibers or particles (e.g., glass, carbon fibers) |

| Mechanical Strength | High tensile strength and enhanced stiffness | Good strength, less than nanocomposites |

| Weight | Lightweight with improved strength-to-weight ratio | Heavier due to larger reinforcements |

| Thermal Stability | Improved thermal resistance at nanoscale | Moderate thermal resistance |

| Barrier Properties | Superior gas and moisture barrier | Lower barrier performance |

| Cost | Higher due to advanced materials and processing | Lower and widely available |

| Applications | Electronics, aerospace, biomedical devices | Automotive parts, construction, consumer goods |

Introduction to Composite Materials

Composite materials combine two or more distinct phases to create a material with enhanced properties not found in individual components. Nanocomposites incorporate nanoparticles as reinforcements, offering superior mechanical strength, thermal stability, and electrical conductivity compared to traditional polymer composites that use micron-sized fillers. The nanoscale dispersion in nanocomposites significantly improves interface interactions and overall performance, advancing applications in aerospace, automotive, and electronics industries.

Defining Nanocomposites and Polymer Composites

Nanocomposites are advanced materials composed of a polymer matrix embedded with nanoscale fillers typically less than 100 nanometers in size, which significantly enhance mechanical, thermal, and barrier properties. Polymer composites consist of a polymer matrix reinforced with microscale fibers or particles, providing improved strength, stiffness, and durability compared to pure polymers. The defining difference lies in the scale of the reinforcement phase, where nanocomposites leverage nanoscale fillers to achieve superior material performance and multifunctionality.

Material Structure and Morphology

Nanocomposites feature a matrix embedded with nanoparticles measuring less than 100 nanometers, which significantly enhances interfacial bonding and surface area compared to conventional polymer composites containing microscale fillers. The nanoscale dispersion in nanocomposites leads to improved material morphology characterized by uniform particle distribution and increased polymer-filler interactions, resulting in superior mechanical, thermal, and barrier properties. In contrast, polymer composites exhibit larger filler agglomerates and less homogeneous morphology, often limiting property enhancements due to weaker interfacial adhesion and reduced filler surface contact.

Synthesis and Fabrication Techniques

Nanocomposites are synthesized through advanced techniques such as in-situ polymerization, sol-gel processes, and electrospinning, enabling uniform dispersion of nanoparticles within polymer matrices to enhance mechanical, thermal, and electrical properties. Polymer composites typically undergo fabrication methods like extrusion, injection molding, and compression molding, which involve blending macro-scale fillers with polymer resins for improved strength and durability. The key distinction lies in nanoparticle integration at the molecular level in nanocomposites, resulting in superior interfacial bonding and enhanced multifunctional performance compared to traditional polymer composites.

Mechanical Properties Comparison

Nanocomposites exhibit significantly enhanced mechanical properties compared to traditional polymer composites due to the incorporation of nanoscale fillers such as carbon nanotubes, graphene, or nanoclays, which provide superior strength, stiffness, and toughness at lower filler loadings. The high surface area to volume ratio of nanofillers enables improved stress transfer and interfacial bonding with the polymer matrix, resulting in increased tensile strength, modulus, and impact resistance. While polymer composites with microscale fillers improve mechanical properties, nanocomposites deliver exceptional enhancements in fatigue resistance and fracture toughness, making them ideal for high-performance engineering applications.

Thermal Stability and Performance

Nanocomposites exhibit superior thermal stability compared to conventional polymer composites due to their enhanced interfacial interactions between nanoscale fillers and polymer matrices. The incorporation of nanofillers such as carbon nanotubes, graphene, or clay minerals significantly improves heat resistance and thermal conductivity, resulting in better performance under high-temperature conditions. Polymer composites with microscale fillers generally display lower thermal stability and reduced mechanical properties at elevated temperatures.

Electrical and Optical Characteristics

Nanocomposites exhibit superior electrical conductivity and enhanced optical transparency compared to traditional polymer composites due to the incorporation of nanoscale fillers such as carbon nanotubes, graphene, or metal nanoparticles. These nanofillers create conductive pathways at lower loading levels, significantly improving electrical properties while maintaining or even enhancing optical clarity by minimizing light scattering. In contrast, conventional polymer composites often suffer from reduced transparency and limited electrical performance because of larger filler sizes and less uniform dispersion.

Applications in Advanced Engineering Fields

Nanocomposites exhibit superior mechanical strength, thermal stability, and electrical conductivity compared to traditional polymer composites, making them ideal for aerospace components, automotive parts, and electronics. Their enhanced barrier properties and lightweight nature enable advanced applications in energy storage devices, sensors, and flexible electronics. Polymer composites, while widely used in construction and consumer goods, often lack the nanoscale reinforcement that drives performance improvements critical in high-tech engineering domains.

Environmental Impact and Sustainability

Nanocomposites offer enhanced environmental benefits compared to traditional polymer composites due to their improved mechanical properties and reduced material usage, leading to lower resource consumption and waste generation. The incorporation of nanomaterials like carbon nanotubes or nanoclays results in lighter, stronger components that improve fuel efficiency in automotive and aerospace sectors, directly reducing carbon emissions. Furthermore, nanocomposites enable better biodegradability and recyclability options, advancing sustainable material design and contributing to a circular economy.

Future Trends in Composite Materials

Nanocomposites exhibit enhanced mechanical, thermal, and electrical properties due to the incorporation of nanoscale fillers like carbon nanotubes and graphene, making them a key focus in the future of composite materials. Polymer composites continue to evolve with bio-based and recycled polymers, promoting sustainability and lightweight applications in aerospace and automotive industries. Emerging trends emphasize multifunctional composites integrating smart sensors, self-healing capabilities, and improved environmental resistance to meet the demands of advanced engineering applications.

Matrix reinforcement

Nanocomposites enhance polymer composite matrices by incorporating nanoscale reinforcements that significantly improve mechanical strength, thermal stability, and barrier properties compared to conventional microscale fillers.

Filler dispersion

Nanocomposites exhibit superior filler dispersion compared to polymer composites due to their nanoscale filler size, which enhances interfacial interaction and uniform distribution within the polymer matrix.

Interfacial bonding

Nanocomposites exhibit significantly enhanced interfacial bonding compared to traditional polymer composites due to their nanoscale filler dispersion, which increases surface area and promotes stronger matrix-filler interactions.

Aspect ratio

Nanocomposites exhibit significantly higher aspect ratios ranging from 10 to over 1000 compared to polymer composites, which typically have aspect ratios below 100, enhancing their mechanical strength and barrier properties.

Percolation threshold

Nanocomposites exhibit significantly lower percolation thresholds than conventional polymer composites due to their nanoscale filler dispersion, enhancing electrical conductivity and mechanical properties at reduced filler content.

Mechanical enhancement

Nanocomposites exhibit significantly superior mechanical enhancement compared to conventional polymer composites due to the incorporation of nanoscale fillers that improve strength, stiffness, and toughness at lower filler loadings.

Nanoscale additives

Nanocomposites utilize nanoscale additives that enhance mechanical, thermal, and barrier properties more effectively than conventional polymer composites with microscale fillers.

Hybrid morphology

Nanocomposites exhibit superior hybrid morphology with nanoscale fillers uniformly dispersed within the polymer matrix, enhancing mechanical, thermal, and barrier properties compared to conventional polymer composites with microscale reinforcements.

Thermal conductivity modulation

Nanocomposites exhibit significantly enhanced thermal conductivity modulation compared to traditional polymer composites due to the incorporation of nanoscale fillers that create efficient heat transfer networks.

Functionalization agents

Functionalization agents in nanocomposites enhance interfacial adhesion and dispersion of nanoparticles, significantly improving mechanical, thermal, and electrical properties compared to conventional polymer composites.

Nanocomposites vs Polymer composites Infographic

njnir.com

njnir.com