High entropy alloys exhibit superior mechanical properties and corrosion resistance compared to conventional alloys due to their multi-principal element composition. This unique atomic structure enhances strength, thermal stability, and wear resistance under extreme conditions. Advances in processing techniques further optimize their microstructure, enabling tailored performance for aerospace, automotive, and energy applications.

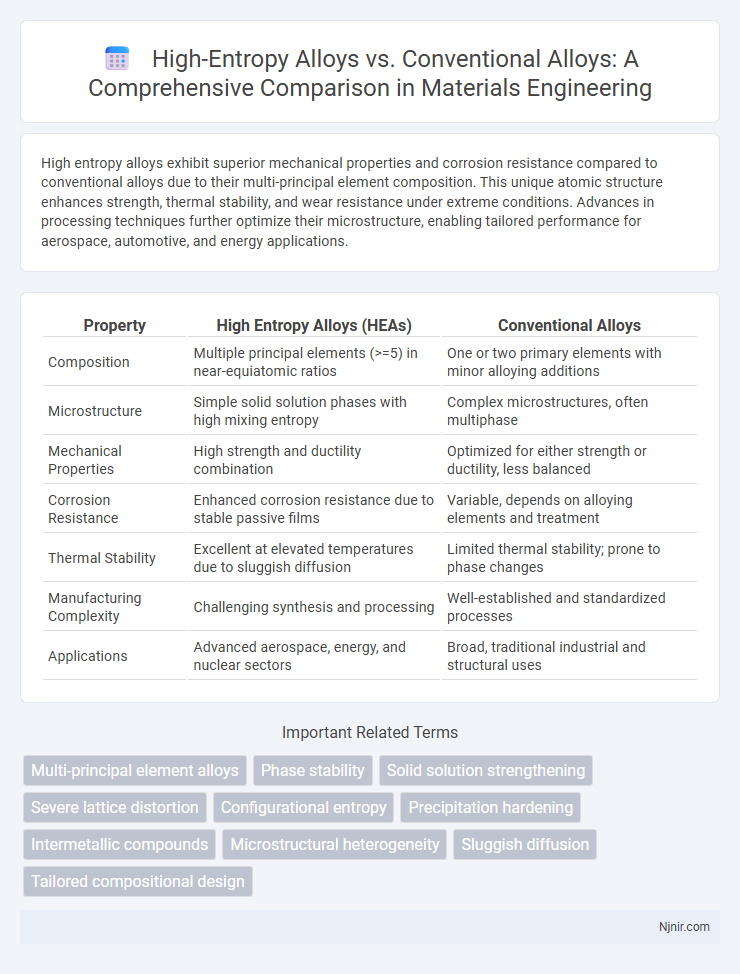

Table of Comparison

| Property | High Entropy Alloys (HEAs) | Conventional Alloys |

|---|---|---|

| Composition | Multiple principal elements (>=5) in near-equiatomic ratios | One or two primary elements with minor alloying additions |

| Microstructure | Simple solid solution phases with high mixing entropy | Complex microstructures, often multiphase |

| Mechanical Properties | High strength and ductility combination | Optimized for either strength or ductility, less balanced |

| Corrosion Resistance | Enhanced corrosion resistance due to stable passive films | Variable, depends on alloying elements and treatment |

| Thermal Stability | Excellent at elevated temperatures due to sluggish diffusion | Limited thermal stability; prone to phase changes |

| Manufacturing Complexity | Challenging synthesis and processing | Well-established and standardized processes |

| Applications | Advanced aerospace, energy, and nuclear sectors | Broad, traditional industrial and structural uses |

Introduction to Alloy Types

High entropy alloys (HEAs) consist of five or more principal elements mixed in nearly equal proportions, resulting in unique phase stability and exceptional mechanical properties compared to conventional alloys, which typically comprise one primary element with smaller amounts of additional components. The complex atomic arrangements in HEAs lead to enhanced strength, corrosion resistance, and thermal stability, distinguishing them from traditional alloys such as stainless steel or aluminum-based materials. Advances in material science leverage HEAs for applications requiring superior performance under extreme conditions not achievable by conventional alloy systems.

Defining High Entropy Alloys

High Entropy Alloys (HEAs) are defined by their composition of five or more principal elements in near-equiatomic proportions, resulting in high configurational entropy that stabilizes simple solid solution phases. This contrasts with conventional alloys, which typically consist of one principal element with minor additions to enhance properties. The unique multi-component nature of HEAs leads to exceptional mechanical strength, thermal stability, and corrosion resistance compared to traditional alloys.

Conventional Alloys: Composition and Characteristics

Conventional alloys typically consist of one principal metal combined with small amounts of other elements to enhance properties such as strength, corrosion resistance, and ductility. Their compositions are well-defined and optimized through years of metallurgical research, often resulting in predictable phase structures and mechanical behaviors. These alloys exhibit a balance of performance traits, making them suitable for a wide range of industrial applications, though their properties may be limited compared to the complex microstructures of high entropy alloys.

Microstructure Differences

High entropy alloys (HEAs) exhibit a complex, multi-element microstructure characterized by a single-phase solid solution with severe lattice distortion, contrasting with the multi-phase microstructures of conventional alloys dominated by one or two principal elements. The high configurational entropy in HEAs stabilizes simple crystal structures such as face-centered cubic (FCC) or body-centered cubic (BCC), reducing the formation of intermetallic compounds common in conventional alloys. This unique microstructure enhances mechanical properties like strength, hardness, and corrosion resistance through mechanisms such as solid solution strengthening and sluggish diffusion.

Mechanical Properties Comparison

High entropy alloys (HEAs) exhibit superior mechanical properties compared to conventional alloys, including enhanced strength, hardness, and fracture toughness due to their complex multi-element composition and high configurational entropy. HEAs demonstrate exceptional resistance to wear, fatigue, and high-temperature deformation, making them highly suitable for extreme environments. Conventional alloys typically show lower strength-to-weight ratios and reduced thermal stability, limiting their performance in demanding mechanical applications.

Corrosion and Oxidation Resistance

High entropy alloys (HEAs) exhibit superior corrosion and oxidation resistance compared to conventional alloys due to their unique multi-principal element composition, which forms stable, passive oxide layers that inhibit degradation. The complex atomic structure of HEAs reduces diffusion rates and enhances protective oxide scale adherence, significantly improving performance in aggressive environments. In contrast, conventional alloys often suffer from localized corrosion and oxide scale spallation, limiting their durability under harsh conditions.

Processing and Fabrication Methods

High entropy alloys (HEAs) often require advanced processing techniques such as powder metallurgy, laser melting, and mechanical alloying to achieve their unique multi-principal element microstructures, whereas conventional alloys typically rely on traditional casting and forging methods. Fabrication of HEAs demands precise control over temperature and cooling rates to maintain phase stability and prevent unwanted segregation, contrasting with the well-established processing windows for conventional alloys. The innovative processing routes for HEAs enable enhanced mechanical properties and corrosion resistance but pose challenges in scalability and cost compared to conventional alloy manufacturing.

Applications in Industry

High entropy alloys (HEAs) exhibit superior mechanical properties, corrosion resistance, and thermal stability, making them ideal for aerospace, automotive, and energy sector applications where extreme conditions prevail. Conventional alloys, such as stainless steel and aluminum alloys, dominate general manufacturing due to established production methods and cost-effectiveness, especially in construction and consumer goods. Industrial use of HEAs is expanding in advanced components like turbine blades and wear-resistant coatings, driven by their ability to maintain performance in harsh environments compared to traditional alloys.

Economic and Environmental Considerations

High entropy alloys (HEAs) offer significant long-term economic benefits by enhancing material durability and reducing maintenance costs compared to conventional alloys, which often require frequent replacement. Environmentally, HEAs contribute to sustainability through improved corrosion resistance and higher temperature performance, leading to less waste and lower energy consumption during manufacturing and service life. Conventional alloys, while currently less expensive upfront, typically have higher environmental footprints due to increased resource extraction and shorter lifecycle durability.

Future Trends in Alloy Development

High entropy alloys (HEAs) exhibit exceptional mechanical properties, corrosion resistance, and thermal stability due to their multi-principal element composition, presenting promising advancements over conventional alloys. Future trends in alloy development emphasize designing HEAs with tailored microstructures via machine learning and additive manufacturing techniques to optimize performance for aerospace, biomedical, and energy applications. Researchers are increasingly focusing on sustainable alloy production, recycling strategies, and alloy systems with enhanced high-temperature stability and lightweight characteristics to meet evolving industrial demands.

Multi-principal element alloys

High entropy alloys, characterized by multi-principal element compositions, exhibit superior mechanical strength, corrosion resistance, and thermal stability compared to conventional single or dual-element alloys.

Phase stability

High entropy alloys exhibit superior phase stability due to their multicomponent equiatomic compositions, which enhance configurational entropy and inhibit phase segregation compared to conventional alloys.

Solid solution strengthening

High entropy alloys exhibit superior solid solution strengthening compared to conventional alloys due to their multicomponent composition, which creates severe lattice distortion and impedes dislocation motion more effectively.

Severe lattice distortion

High entropy alloys exhibit severe lattice distortion due to their multi-component composition, resulting in enhanced mechanical properties compared to conventional alloys with more uniform atomic arrangements.

Configurational entropy

High entropy alloys exhibit significantly higher configurational entropy than conventional alloys, enhancing their phase stability and mechanical properties through the formation of multi-component solid solutions.

Precipitation hardening

High entropy alloys exhibit enhanced precipitation hardening due to their complex multi-element compositions, which promote finer and more stable precipitate distributions compared to conventional alloys.

Intermetallic compounds

High entropy alloys exhibit enhanced mechanical properties and thermal stability by minimizing brittle intermetallic compounds compared to conventional alloys, which commonly form coarse and brittle intermetallic phases.

Microstructural heterogeneity

High entropy alloys exhibit enhanced microstructural heterogeneity compared to conventional alloys, resulting in superior mechanical properties and thermal stability.

Sluggish diffusion

High entropy alloys exhibit significantly sluggish diffusion rates compared to conventional alloys due to their complex multi-element compositions, enhancing thermal stability and mechanical performance.

Tailored compositional design

Tailored compositional design in high entropy alloys enables unprecedented customization of mechanical and thermal properties compared to conventional alloys by leveraging multiple principal elements in near-equimolar ratios.

High entropy alloys vs Conventional alloys Infographic

njnir.com

njnir.com