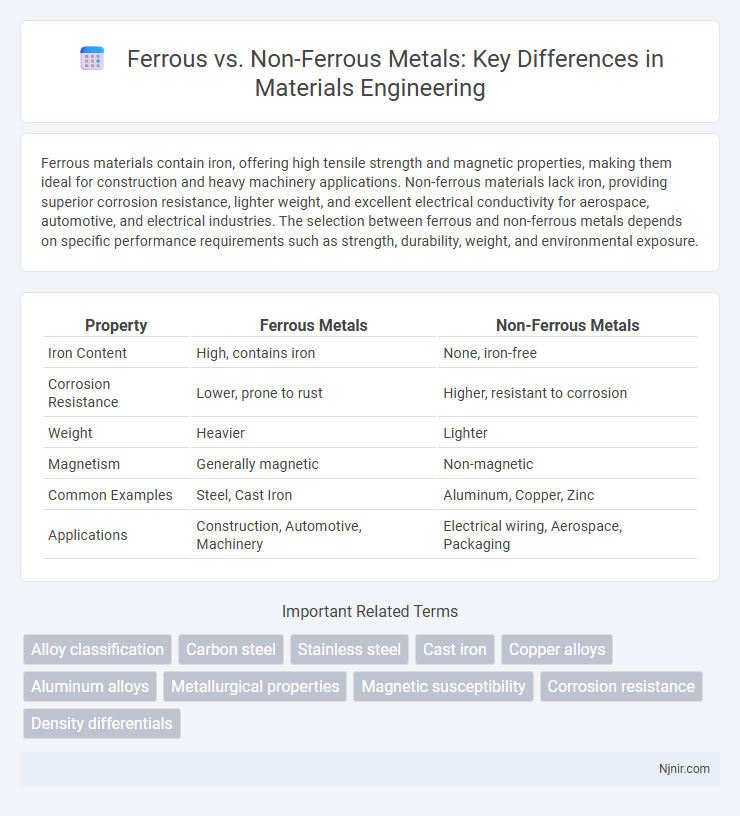

Ferrous materials contain iron, offering high tensile strength and magnetic properties, making them ideal for construction and heavy machinery applications. Non-ferrous materials lack iron, providing superior corrosion resistance, lighter weight, and excellent electrical conductivity for aerospace, automotive, and electrical industries. The selection between ferrous and non-ferrous metals depends on specific performance requirements such as strength, durability, weight, and environmental exposure.

Table of Comparison

| Property | Ferrous Metals | Non-Ferrous Metals |

|---|---|---|

| Iron Content | High, contains iron | None, iron-free |

| Corrosion Resistance | Lower, prone to rust | Higher, resistant to corrosion |

| Weight | Heavier | Lighter |

| Magnetism | Generally magnetic | Non-magnetic |

| Common Examples | Steel, Cast Iron | Aluminum, Copper, Zinc |

| Applications | Construction, Automotive, Machinery | Electrical wiring, Aerospace, Packaging |

Introduction to Ferrous and Non-Ferrous Materials

Ferrous materials contain iron as the main element, making them magnetic and prone to rust, commonly found in steel and cast iron alloys. Non-ferrous materials lack iron, offering superior resistance to corrosion and excellent electrical conductivity, such as aluminum, copper, and brass. The distinct properties of ferrous and non-ferrous metals determine their applications in construction, automotive, and electrical industries.

Chemical Composition Differences

Ferrous metals primarily contain iron with carbon as the main alloying element, which imparts magnetic properties and susceptibility to rusting due to oxidation. Non-ferrous metals lack iron, resulting in higher corrosion resistance, non-magnetic characteristics, and often improved electrical conductivity. Common ferrous materials include steel and cast iron, while aluminum, copper, and brass exemplify non-ferrous alloys distinguished by their unique elemental compositions such as aluminum, copper, and zinc.

Physical and Mechanical Properties

Ferrous metals contain iron, exhibiting high tensile strength, magnetic properties, and excellent durability, making them ideal for construction and heavy machinery applications. Non-ferrous metals lack iron, offering superior corrosion resistance, lighter weight, and higher conductivity, which suits electrical wiring and aerospace components. Mechanical properties such as hardness, ductility, and melting point vary significantly, with ferrous metals generally stronger but non-ferrous metals more versatile for specialized environments.

Corrosion Resistance Comparison

Ferrous metals, primarily composed of iron, generally exhibit lower corrosion resistance due to their tendency to oxidize and form rust when exposed to moisture and oxygen. Non-ferrous metals such as aluminum, copper, and stainless steel possess a natural resistance to corrosion because of their ability to form protective oxide layers or resist oxidation processes. This inherent corrosion resistance makes non-ferrous metals ideal for applications requiring longevity in harsh environments or exposure to chemicals.

Common Types and Examples

Ferrous metals primarily contain iron, with common types including carbon steel, cast iron, and stainless steel, known for their strength and magnetic properties. Non-ferrous metals lack iron and include aluminum, copper, lead, zinc, and nickel, valued for their resistance to corrosion and lightweight characteristics. Applications often dictate the choice between ferrous and non-ferrous metals based on properties like durability, conductivity, and weight.

Manufacturing and Processing Techniques

Ferrous metals, primarily composed of iron and steel, are typically processed using techniques such as casting, forging, and welding due to their magnetic properties and higher tensile strength. Non-ferrous metals like aluminum, copper, and zinc undergo specialized manufacturing methods including extrusion, rolling, and powder metallurgy to preserve their corrosion resistance and electrical conductivity. Advanced techniques such as CNC machining and additive manufacturing are increasingly applied to both ferrous and non-ferrous materials to enhance precision and efficiency in complex component production.

Applications in Modern Industries

Ferrous metals, including steel and cast iron, dominate construction, automotive manufacturing, and heavy machinery due to their strength, durability, and magnetic properties. Non-ferrous metals such as aluminum, copper, and titanium are essential in aerospace, electrical wiring, and corrosion-resistant applications because of their lightweight nature, excellent conductivity, and resistance to rust. Modern industries leverage the specific physical and chemical properties of ferrous and non-ferrous metals to optimize performance, cost, and sustainability in various engineering and manufacturing processes.

Environmental Impact and Recyclability

Ferrous metals, primarily composed of iron and steel, are highly recyclable, with recycling rates often exceeding 90%, significantly reducing environmental impact by conserving natural resources and lowering energy consumption. Non-ferrous metals such as aluminum, copper, and zinc also offer excellent recyclability but differ in environmental impact due to more energy-intensive extraction processes and potential toxicity concerns. Efficient recycling of both ferrous and non-ferrous metals mitigates landfill waste, reduces greenhouse gas emissions, and conserves raw materials critical for sustainable resource management.

Cost and Market Availability

Ferrous metals, primarily composed of iron and steel, generally offer lower costs due to abundant raw material supply and established recycling infrastructure, making them widely available in global markets. Non-ferrous metals such as aluminum, copper, and zinc exhibit higher market prices driven by their corrosion resistance, electrical conductivity, and limited supply compared to ferrous metals. Market availability of non-ferrous metals can fluctuate significantly with geopolitical factors and mining output, impacting cost stability and procurement strategies.

Future Trends in Material Selection

Future trends in material selection highlight a growing preference for non-ferrous metals like aluminum, copper, and titanium due to their lightweight, corrosion resistance, and excellent conductivity properties. Innovations in alloy composition and recycling technology are making ferrous metals such as advanced high-strength steels more sustainable and cost-effective for automotive and construction industries. Emerging industries, including aerospace and renewable energy, drive the demand for tailored non-ferrous materials that enhance performance while reducing environmental impact.

Alloy classification

Ferrous alloys primarily contain iron and include steels and cast irons, while non-ferrous alloys are metal mixtures without iron, such as aluminum alloys, copper alloys, and titanium alloys, each classified based on their distinct properties and applications.

Carbon steel

Carbon steel, a ferrous metal primarily composed of iron and carbon, offers high strength and durability compared to non-ferrous metals, which lack iron and typically provide better corrosion resistance and electrical conductivity.

Stainless steel

Stainless steel is a ferrous alloy primarily composed of iron, chromium, and nickel, offering superior corrosion resistance compared to non-ferrous metals.

Cast iron

Cast iron, a ferrous metal containing high carbon content, exhibits superior hardness and wear resistance compared to non-ferrous metals, making it ideal for heavy-duty industrial applications.

Copper alloys

Copper alloys, categorized as non-ferrous metals, exhibit superior corrosion resistance, electrical conductivity, and malleability compared to ferrous metals primarily composed of iron.

Aluminum alloys

Aluminum alloys, as non-ferrous metals, offer superior corrosion resistance, lightweight properties, and high conductivity compared to ferrous metals, making them ideal for aerospace, automotive, and construction applications.

Metallurgical properties

Ferrous metals contain iron and exhibit magnetic properties, high tensile strength, and susceptibility to corrosion, whereas non-ferrous metals lack iron, offer superior corrosion resistance, lightweight characteristics, and excellent electrical conductivity.

Magnetic susceptibility

Ferrous metals exhibit high magnetic susceptibility due to their iron content, while non-ferrous metals generally have low or negligible magnetic susceptibility.

Corrosion resistance

Non-ferrous metals such as aluminum, copper, and stainless steel exhibit superior corrosion resistance compared to ferrous metals like iron and carbon steel, making them ideal for applications exposed to moisture and harsh environments.

Density differentials

Ferrous metals typically have higher densities ranging from 7.7 to 8.0 g/cm3 compared to non-ferrous metals whose densities vary widely from around 2.7 g/cm3 in aluminum to 8.9 g/cm3 in copper, influencing their applications based on weight and strength requirements.

Ferrous vs Non-ferrous Infographic

njnir.com

njnir.com