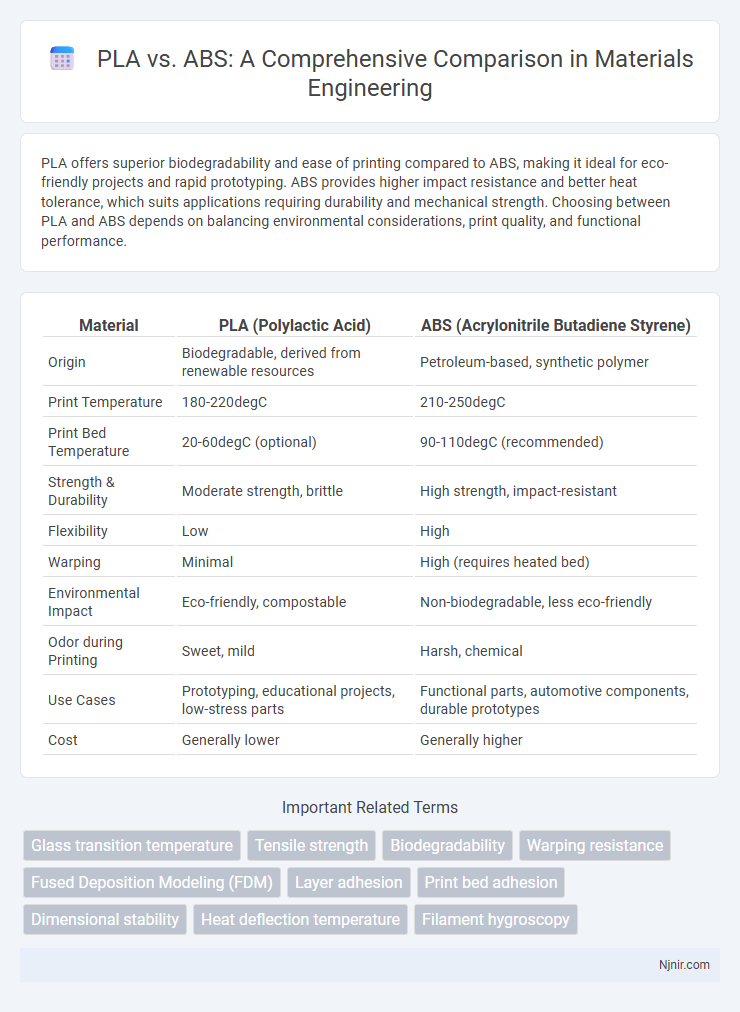

PLA offers superior biodegradability and ease of printing compared to ABS, making it ideal for eco-friendly projects and rapid prototyping. ABS provides higher impact resistance and better heat tolerance, which suits applications requiring durability and mechanical strength. Choosing between PLA and ABS depends on balancing environmental considerations, print quality, and functional performance.

Table of Comparison

| Material | PLA (Polylactic Acid) | ABS (Acrylonitrile Butadiene Styrene) |

|---|---|---|

| Origin | Biodegradable, derived from renewable resources | Petroleum-based, synthetic polymer |

| Print Temperature | 180-220degC | 210-250degC |

| Print Bed Temperature | 20-60degC (optional) | 90-110degC (recommended) |

| Strength & Durability | Moderate strength, brittle | High strength, impact-resistant |

| Flexibility | Low | High |

| Warping | Minimal | High (requires heated bed) |

| Environmental Impact | Eco-friendly, compostable | Non-biodegradable, less eco-friendly |

| Odor during Printing | Sweet, mild | Harsh, chemical |

| Use Cases | Prototyping, educational projects, low-stress parts | Functional parts, automotive components, durable prototypes |

| Cost | Generally lower | Generally higher |

Chemical Structure and Composition

PLA (Polylactic Acid) is a biodegradable thermoplastic derived from renewable resources like corn starch or sugarcane, composed of repeating lactic acid units with ester functional groups in its polymer backbone. ABS (Acrylonitrile Butadiene Styrene) is a petroleum-based thermoplastic composed of three monomers: acrylonitrile, butadiene, and styrene, forming a copolymer with a complex chain structure that provides strength and impact resistance. The difference in chemical composition results in PLA being more environmentally friendly with lower-temperature resistance, whereas ABS offers higher durability and heat resistance due to its copolymer architecture.

Mechanical Properties Comparison

PLA exhibits higher tensile strength and stiffness, with a tensile strength ranging from 50 to 70 MPa and a Young's modulus of about 3.5 GPa, making it suitable for rigid applications. ABS offers superior impact resistance and flexibility, with an impact strength around 15 kJ/m2 and a tensile elongation at break of up to 30%, providing better durability under mechanical stress. The thermal resistance of ABS typically exceeds PLA, maintaining structural integrity at temperatures above 100degC compared to PLA's lower heat deflection temperature near 60degC.

Thermal Resistance and Processing Temperatures

PLA exhibits lower thermal resistance with a glass transition temperature around 60degC, making it prone to deformation under moderate heat. ABS offers higher thermal resistance, with a glass transition temperature near 105degC, allowing it to withstand higher temperatures without softening. Processing temperatures for PLA typically range from 180degC to 220degC, while ABS requires higher extrusion temperatures between 220degC and 250degC for optimal print quality.

Environmental Impact and Biodegradability

PLA (Polylactic Acid) is derived from renewable resources such as corn starch, making it more environmentally friendly compared to ABS (Acrylonitrile Butadiene Styrene), which is petroleum-based. PLA is biodegradable under industrial composting conditions, breaking down into water and carbon dioxide within a few months, while ABS is non-biodegradable and persists in the environment for decades. The lower carbon footprint and compostability of PLA contribute to reduced long-term environmental pollution compared to the more toxic emissions during ABS production and disposal.

Ease of 3D Printing and User-Friendliness

PLA offers superior ease of 3D printing due to its low warping tendency and no requirement for a heated bed, making it highly user-friendly for beginners. ABS requires higher printing temperatures and a heated build platform to prevent warping, presenting challenges for novice users. PLA's biodegradability and lower odor emission further enhance its suitability for desktop 3D printers in indoor environments.

Surface Finish and Aesthetic Qualities

PLA offers a smoother surface finish with a natural glossy sheen, making it ideal for visually appealing prints and detailed models. ABS tends to have a matte finish with a slightly rougher texture, requiring post-processing like sanding or acetone vapor smoothing for improved aesthetics. The choice between PLA and ABS significantly impacts the final look and feel of 3D printed objects, influencing projects where visual quality is paramount.

Post-Processing Techniques and Compatibility

PLA exhibits excellent compatibility with sanding, painting, and vapor smoothing using ethyl acetate, allowing smooth finishes without warping. ABS responds well to acetone vapor smoothing, which creates glossy surfaces and enhances layer adhesion, though it may require careful ventilation due to fumes. Both materials benefit from heat treatments like annealing to improve mechanical properties, but PLA is more prone to deformation during post-processing compared to ABS.

Common Applications in Industry

PLA is widely used in rapid prototyping and medical devices due to its biodegradability and ease of printing, making it ideal for creating detailed models and eco-friendly packaging solutions. ABS finds extensive application in automotive parts, consumer electronics casings, and durable household goods thanks to its high impact resistance, heat tolerance, and toughness. Both materials play critical roles in additive manufacturing, with PLA preferred for environmentally conscious projects and ABS for robust, functional components.

Cost Analysis and Market Availability

PLA (Polylactic Acid) generally costs less than ABS (Acrylonitrile Butadiene Styrene) due to its bio-based ingredients and simpler manufacturing process. Market availability of PLA is higher in consumer segments and educational use, driven by its eco-friendly appeal and ease of printing, while ABS remains prevalent in industrial applications for its strength and heat resistance. The cost-effectiveness of PLA combined with its widespread distribution makes it the preferred choice for budget-conscious makers and prototyping.

Selection Guidelines for Engineering Projects

PLA offers ease of printing and biodegradability, making it ideal for prototyping and non-load-bearing components in engineering projects. ABS provides superior impact resistance, heat tolerance up to 105degC, and durability, which are essential for functional parts requiring strength and thermal stability. Selecting between PLA and ABS depends on project requirements such as mechanical properties, thermal resistance, and environmental considerations.

Glass transition temperature

PLA has a glass transition temperature around 60degC, making it less heat-resistant than ABS, which typically has a glass transition temperature near 105degC.

Tensile strength

PLA exhibits tensile strength ranging from 50 to 70 MPa, generally higher than ABS, which typically ranges between 40 to 60 MPa, making PLA preferable for applications requiring greater tensile durability.

Biodegradability

PLA is biodegradable within industrial composting conditions, while ABS is non-biodegradable and persists in the environment.

Warping resistance

ABS exhibits superior warping resistance compared to PLA, making it more suitable for 3D printing applications that require dimensional stability and high-temperature endurance.

Fused Deposition Modeling (FDM)

PLA offers easier printability and biodegradability for Fused Deposition Modeling (FDM) compared to ABS, which provides higher strength and heat resistance but requires elevated printing temperatures and an enclosed build chamber.

Layer adhesion

PLA exhibits stronger layer adhesion than ABS, resulting in better structural integrity and less warping during 3D printing.

Print bed adhesion

PLA offers superior print bed adhesion on standard heated beds at lower temperatures compared to ABS, which typically requires higher bed temperatures and additional surface preparation for effective adhesion.

Dimensional stability

PLA exhibits lower dimensional stability compared to ABS due to its higher tendency to warp and shrink under heat, making ABS more suitable for precise and functional 3D prints.

Heat deflection temperature

PLA has a heat deflection temperature around 60degC, whereas ABS withstands higher temperatures up to approximately 105degC, making ABS more suitable for heat-resistant applications.

Filament hygroscopy

PLA filament absorbs less moisture than ABS, making PLA less hygroscopic and easier to store without degradation.

PLA vs ABS Infographic

njnir.com

njnir.com