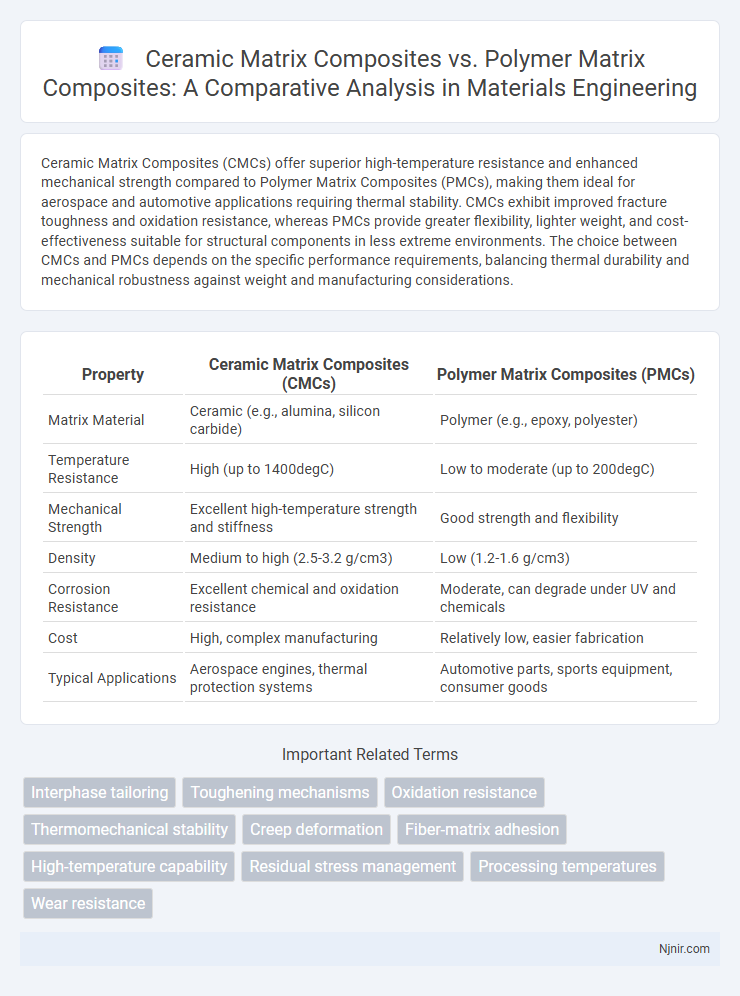

Ceramic Matrix Composites (CMCs) offer superior high-temperature resistance and enhanced mechanical strength compared to Polymer Matrix Composites (PMCs), making them ideal for aerospace and automotive applications requiring thermal stability. CMCs exhibit improved fracture toughness and oxidation resistance, whereas PMCs provide greater flexibility, lighter weight, and cost-effectiveness suitable for structural components in less extreme environments. The choice between CMCs and PMCs depends on the specific performance requirements, balancing thermal durability and mechanical robustness against weight and manufacturing considerations.

Table of Comparison

| Property | Ceramic Matrix Composites (CMCs) | Polymer Matrix Composites (PMCs) |

|---|---|---|

| Matrix Material | Ceramic (e.g., alumina, silicon carbide) | Polymer (e.g., epoxy, polyester) |

| Temperature Resistance | High (up to 1400degC) | Low to moderate (up to 200degC) |

| Mechanical Strength | Excellent high-temperature strength and stiffness | Good strength and flexibility |

| Density | Medium to high (2.5-3.2 g/cm3) | Low (1.2-1.6 g/cm3) |

| Corrosion Resistance | Excellent chemical and oxidation resistance | Moderate, can degrade under UV and chemicals |

| Cost | High, complex manufacturing | Relatively low, easier fabrication |

| Typical Applications | Aerospace engines, thermal protection systems | Automotive parts, sports equipment, consumer goods |

Introduction to Matrix Composites

Matrix composites are engineered materials composed of a reinforcing phase embedded within a continuous matrix phase, significantly enhancing mechanical properties such as strength, stiffness, and thermal stability. Ceramic Matrix Composites (CMCs) utilize ceramic materials as the matrix, offering exceptional high-temperature resistance and chemical stability, making them suitable for aerospace and automotive applications. Polymer Matrix Composites (PMCs), on the other hand, feature polymer resins as the matrix, providing lightweight characteristics and ease of fabrication, commonly used in sports equipment and structural components.

Overview of Ceramic Matrix Composites (CMCs)

Ceramic Matrix Composites (CMCs) consist of ceramic fibers embedded in a ceramic matrix, offering exceptional high-temperature resistance and enhanced toughness compared to monolithic ceramics. These composites exhibit superior thermal stability, low density, and excellent corrosion resistance, making them ideal for aerospace, automotive, and energy applications. CMCs outperform Polymer Matrix Composites (PMCs) in extreme environments due to their ability to maintain structural integrity at temperatures above 1,200degC.

Overview of Polymer Matrix Composites (PMCs)

Polymer Matrix Composites (PMCs) consist of a polymer resin matrix reinforced with fibers such as glass, carbon, or aramid, providing lightweight properties and excellent corrosion resistance. PMCs exhibit high strength-to-weight ratios and good fatigue resistance, making them ideal for aerospace, automotive, and sporting goods applications. Compared to Ceramic Matrix Composites, PMCs offer easier processing and lower cost but lower temperature resistance and reduced stiffness.

Material Composition and Structure Comparison

Ceramic Matrix Composites (CMCs) consist of ceramic fibers embedded within a ceramic matrix, offering exceptional high-temperature resistance, stiffness, and thermal stability due to their crystalline structure and strong ionic or covalent bonds. Polymer Matrix Composites (PMCs) comprise polymer fibers, such as carbon or glass, reinforced within a polymer resin matrix, providing lower density, higher toughness, and greater flexibility but limited thermal resistance compared to CMCs. The fundamental difference lies in CMCs' inorganic, rigid ceramic phases versus PMCs' organic polymer phases, critically influencing their mechanical properties, temperature tolerance, and applications in aerospace and automotive industries.

Mechanical Properties: Strength and Toughness

Ceramic Matrix Composites (CMCs) exhibit superior high-temperature strength and excellent fracture toughness compared to Polymer Matrix Composites (PMCs), making them ideal for extreme thermal environments. PMCs generally provide higher toughness and better impact resistance due to their ductile polymer phase but have lower strength and thermal stability. The selection between CMCs and PMCs depends heavily on the required balance of mechanical strength, toughness, and operating temperature ranges.

Thermal Stability and Performance

Ceramic Matrix Composites (CMCs) exhibit superior thermal stability compared to Polymer Matrix Composites (PMCs), maintaining structural integrity at temperatures exceeding 1,200degC, whereas PMCs typically degrade above 300degC. The high melting points and excellent oxidation resistance of ceramic fibers like silicon carbide enhance the thermal performance of CMCs in aerospace and industrial applications. Polymer Matrix Composites, with lower thermal resilience, are better suited for moderate-temperature environments but offer advantages in weight and flexibility.

Manufacturing Processes and Techniques

Ceramic Matrix Composites (CMCs) primarily use processes like chemical vapor infiltration (CVI) and liquid silicon infiltration (LSI) to achieve high-temperature resistance and structural stability, whereas Polymer Matrix Composites (PMCs) often rely on resin transfer molding (RTM) and autoclave curing for lightweight and versatile design applications. CMC manufacturing requires precise control of fiber architecture and matrix composition to enhance thermal and mechanical properties, contrasting with the simpler, faster curing cycles typical of PMCs. Advanced techniques such as hot pressing and sintering are critical for CMC densification, while PMCs benefit from advances in thermosetting and thermoplastic resin formulations that improve toughness and manufacturability.

Applications in Industry and Technology

Ceramic Matrix Composites (CMCs) are widely used in aerospace and energy industries due to their high-temperature resistance and superior mechanical properties, making them ideal for turbine engines and heat shields. Polymer Matrix Composites (PMCs) dominate automotive, sporting goods, and electronic industries because of their lightweight, corrosion resistance, and ease of manufacturing. Both materials are crucial in advancing technology, with CMCs enabling extreme environment applications and PMCs supporting mass production and structural flexibility.

Cost Analysis and Economic Considerations

Ceramic Matrix Composites (CMCs) generally incur higher production costs than Polymer Matrix Composites (PMCs) due to expensive raw materials and complex manufacturing processes such as high-temperature sintering. Despite their higher initial costs, CMCs offer superior high-temperature performance and durability, leading to lower lifecycle expenses in aerospace and automotive applications. PMCs provide a cost-effective solution for less demanding environments with faster fabrication times and lower material costs, making them economically favorable for mass production and lightweight structural components.

Future Trends and Innovations in Composite Materials

Ceramic Matrix Composites (CMCs) and Polymer Matrix Composites (PMCs) are evolving with advancements in nanotechnology and sustainable material integration, driving enhanced performance for aerospace and automotive applications. Future trends include the development of multifunctional composites with self-healing properties, improved thermal resistance in CMCs, and bio-based, recyclable polymers in PMCs to address environmental challenges. Innovations also focus on additive manufacturing techniques enabling complex geometries and tailored microstructures, optimizing mechanical strength and reducing production costs in both CMCs and PMCs.

Interphase tailoring

Interphase tailoring in Ceramic Matrix Composites enhances thermal stability and crack resistance by optimizing the fiber-matrix interface, whereas in Polymer Matrix Composites, it improves load transfer and toughness by modifying interfacial adhesion and chemical compatibility.

Toughening mechanisms

Ceramic Matrix Composites exhibit enhanced toughness through mechanisms such as crack deflection, fiber bridging, and residual compressive stresses, while Polymer Matrix Composites primarily rely on fiber pull-out, matrix yielding, and energy absorption through plastic deformation for toughening.

Oxidation resistance

Ceramic Matrix Composites exhibit superior oxidation resistance compared to Polymer Matrix Composites, making them more suitable for high-temperature and oxidative environments.

Thermomechanical stability

Ceramic Matrix Composites (CMCs) exhibit superior thermomechanical stability compared to Polymer Matrix Composites (PMCs), maintaining structural integrity and mechanical strength at temperatures exceeding 1000degC, whereas PMCs typically degrade above 200degC.

Creep deformation

Ceramic Matrix Composites exhibit significantly higher resistance to creep deformation at elevated temperatures compared to Polymer Matrix Composites, making them more suitable for high-temperature structural applications.

Fiber-matrix adhesion

Ceramic Matrix Composites exhibit superior fiber-matrix adhesion compared to Polymer Matrix Composites, resulting in enhanced thermal stability and mechanical strength under high-temperature conditions.

High-temperature capability

Ceramic matrix composites (CMCs) outperform polymer matrix composites (PMCs) in high-temperature capability due to their superior thermal stability, with CMCs sustaining structural integrity above 1,200degC while PMCs typically degrade beyond 250degC.

Residual stress management

Ceramic Matrix Composites exhibit superior residual stress management compared to Polymer Matrix Composites due to their higher thermal stability and enhanced interface bonding characteristics.

Processing temperatures

Ceramic Matrix Composites withstand processing temperatures above 1200degC, significantly higher than Polymer Matrix Composites, which typically process below 400degC.

Wear resistance

Ceramic Matrix Composites offer significantly higher wear resistance than Polymer Matrix Composites due to their superior hardness and thermal stability in abrasive environments.

Ceramic Matrix Composites vs Polymer Matrix Composites Infographic

njnir.com

njnir.com