Nanocellulose offers a sustainable and biodegradable alternative to carbon nanotubes, boasting high tensile strength and excellent surface area for composite reinforcement. While carbon nanotubes provide superior electrical conductivity and mechanical performance, nanocellulose excels in lightweight applications with lower environmental impact. The choice between these materials depends on the specific requirements for conductivity, strength, and sustainability in advanced materials engineering.

Table of Comparison

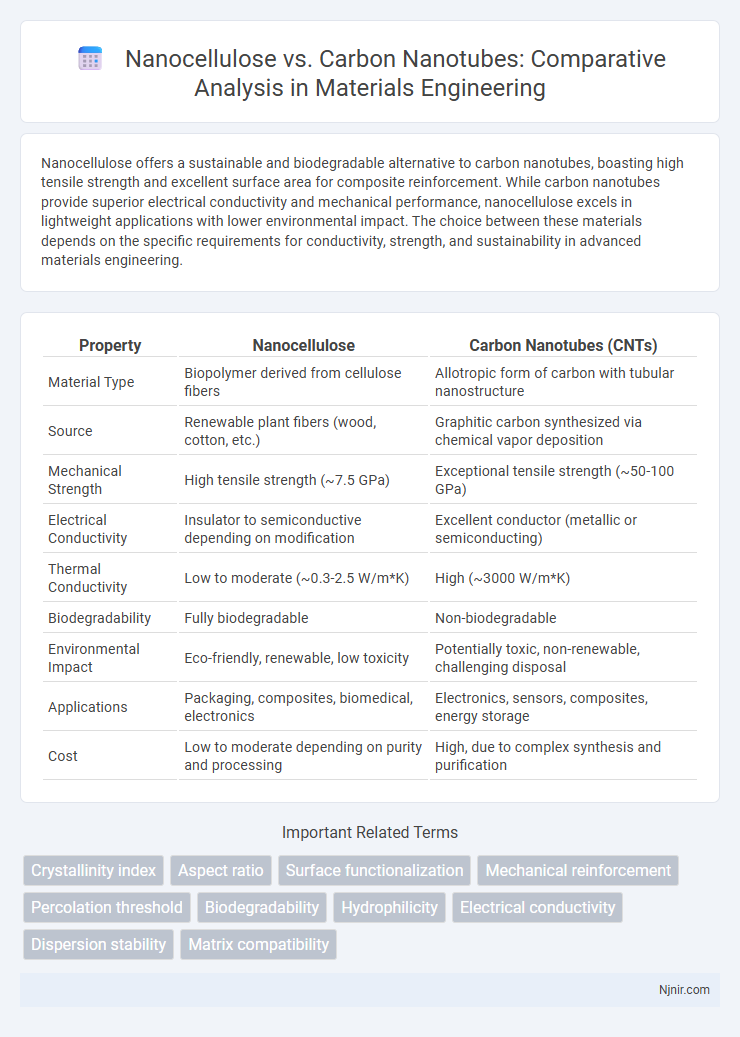

| Property | Nanocellulose | Carbon Nanotubes (CNTs) |

|---|---|---|

| Material Type | Biopolymer derived from cellulose fibers | Allotropic form of carbon with tubular nanostructure |

| Source | Renewable plant fibers (wood, cotton, etc.) | Graphitic carbon synthesized via chemical vapor deposition |

| Mechanical Strength | High tensile strength (~7.5 GPa) | Exceptional tensile strength (~50-100 GPa) |

| Electrical Conductivity | Insulator to semiconductive depending on modification | Excellent conductor (metallic or semiconducting) |

| Thermal Conductivity | Low to moderate (~0.3-2.5 W/m*K) | High (~3000 W/m*K) |

| Biodegradability | Fully biodegradable | Non-biodegradable |

| Environmental Impact | Eco-friendly, renewable, low toxicity | Potentially toxic, non-renewable, challenging disposal |

| Applications | Packaging, composites, biomedical, electronics | Electronics, sensors, composites, energy storage |

| Cost | Low to moderate depending on purity and processing | High, due to complex synthesis and purification |

Introduction to Nanocellulose and Carbon Nanotubes

Nanocellulose, derived from natural cellulose fibers, offers remarkable mechanical strength, biodegradability, and high surface area, making it an eco-friendly nanomaterial for various industrial applications. Carbon nanotubes (CNTs) are cylindrical nanostructures composed of carbon atoms with exceptional electrical conductivity, tensile strength, and thermal stability, widely utilized in electronics, composites, and energy storage. Both nanocellulose and carbon nanotubes exhibit unique nanoscale properties that enable advancements in materials science, yet differ significantly in origin, environmental impact, and specific functional uses.

Structural Differences: Nanocellulose vs Carbon Nanotubes

Nanocellulose consists of cellulose fibrils with a high aspect ratio, characterized by a crystalline structure derived from plant fibers, offering biodegradability and mechanical flexibility. Carbon nanotubes (CNTs) are cylindrical nanostructures composed of sp2-bonded carbon atoms arranged in a hexagonal lattice, providing exceptional tensile strength and electrical conductivity. The key structural difference lies in nanocellulose's organic polymer matrix versus the purely carbon-based, tubular architecture of CNTs, influencing their respective mechanical, thermal, and electrical properties.

Synthesis and Production Methods

Nanocellulose is typically synthesized through mechanical fibrillation, acid hydrolysis, or enzymatic treatment of cellulose-rich biomass, offering a scalable and renewable production method. Carbon nanotubes are produced primarily via chemical vapor deposition, arc discharge, or laser ablation techniques, which require high energy input and specialized equipment. The sustainable and eco-friendly nature of nanocellulose synthesis contrasts with the complex and resource-intensive production processes of carbon nanotubes.

Mechanical Properties Comparison

Nanocellulose exhibits high tensile strength ranging from 7 to 10 GPa, coupled with a Young's modulus of approximately 100-150 GPa, offering excellent stiffness and lightweight characteristics. Carbon nanotubes outperform nanocellulose in mechanical properties, with tensile strength values up to 63 GPa and a Young's modulus exceeding 1 TPa, making them ideal for ultra-strong and high-performance composite materials. While carbon nanotubes provide superior strength and modulus, nanocellulose offers biocompatibility and sustainability, making both materials valuable for different high-strength applications.

Electrical and Thermal Conductivity

Nanocellulose offers moderate electrical conductivity mainly when chemically modified or combined with conductive materials, while carbon nanotubes (CNTs) exhibit exceptional intrinsic electrical conductivity due to their unique graphene-like structure, supporting highly efficient electron transport. Thermal conductivity in nanocellulose is relatively low but can be enhanced through structural alignment or composite formation, whereas carbon nanotubes possess outstanding thermal conductivity, exceeding that of copper, making them ideal for heat dissipation applications. The distinct molecular architecture of CNTs enables superior performance in both electrical and thermal domains compared to nanocellulose, which is more valued for its biodegradability and mechanical properties.

Environmental Impact and Sustainability

Nanocellulose, derived from renewable biomass, offers biodegradability and low environmental toxicity compared to carbon nanotubes, which involve energy-intensive manufacturing and potential ecological risks. The sustainable sourcing of nanocellulose from wood pulp or agricultural waste reduces carbon footprint, while carbon nanotubes require fossil-fuel-based precursors and generate hazardous byproducts. Nanocellulose's compatibility with circular economy principles enhances its appeal for green technologies, whereas carbon nanotubes raise concerns over long-term environmental persistence and bioaccumulation.

Cost and Scalability in Industrial Applications

Nanocellulose offers significantly lower production costs compared to carbon nanotubes due to its abundant raw material sources like wood pulp and simpler manufacturing processes. Scalability of nanocellulose is enhanced by existing biomass processing infrastructure and eco-friendly methods, enabling mass industrial production. In contrast, carbon nanotubes involve high-cost synthesis techniques such as chemical vapor deposition and face challenges in uniformity and volume scale-up, limiting widespread industrial adoption.

Applications in Advanced Materials Engineering

Nanocellulose and carbon nanotubes both play crucial roles in advanced materials engineering due to their exceptional mechanical strength and lightweight properties. Nanocellulose is increasingly used in biodegradable composites, flexible electronics, and high-performance packaging materials, benefiting from its renewable origin and biocompatibility. Carbon nanotubes excel in applications requiring superior electrical conductivity and thermal stability, such as in aerospace components, lightweight conductive composites, and next-generation energy storage devices.

Challenges and Limitations

Nanocellulose faces challenges such as limited thermal stability and moisture sensitivity, which hinder its application in high-temperature or humid environments compared to carbon nanotubes (CNTs). CNTs exhibit excellent electrical conductivity and mechanical strength but suffer from high production costs, scalability issues, and potential health risks due to their cytotoxicity. Both materials require advancements in processing techniques and surface functionalization to overcome dispersion problems and compatibility with various matrices in composite applications.

Future Prospects and Emerging Trends

Nanocellulose and carbon nanotubes both exhibit promising future prospects in advanced material applications, with nanocellulose gaining attention for its sustainability, biodegradability, and strong mechanical properties suitable for packaging, biomedical, and electronics industries. Emerging trends emphasize the hybridization of nanocellulose with carbon nanotubes to enhance electrical conductivity and mechanical strength in composites, fostering innovations in flexible electronics and energy storage devices. Research continues to expand on scalable production methods and functionalization techniques that improve dispersion and compatibility, driving commercial viability in next-generation nanomaterials.

Crystallinity index

Nanocellulose exhibits a high crystallinity index typically ranging from 60% to 90%, surpassing many carbon nanotubes whose crystallinity varies widely but generally shows lower ordered structures due to defects and amorphous carbon presence.

Aspect ratio

Nanocellulose exhibits a high aspect ratio typically ranging from 50 to 1000, which enhances its mechanical reinforcement properties, whereas carbon nanotubes possess an exceptionally high aspect ratio often exceeding 1000, contributing to superior tensile strength and electrical conductivity in composite materials.

Surface functionalization

Surface functionalization of nanocellulose enhances its hydrophilicity and biocompatibility, while carbon nanotubes require complex functionalization to improve solubility and reduce toxicity for advanced material applications.

Mechanical reinforcement

Nanocellulose offers superior mechanical reinforcement due to its high tensile strength, low density, and biodegradability compared to carbon nanotubes, which provide exceptional stiffness but pose challenges in dispersion and environmental impact.

Percolation threshold

Nanocellulose exhibits a lower percolation threshold compared to carbon nanotubes due to its high aspect ratio and superior dispersion in polymer matrices, enhancing electrical conductivity at reduced filler loadings.

Biodegradability

Nanocellulose offers superior biodegradability compared to carbon nanotubes, making it an eco-friendly alternative in sustainable material applications.

Hydrophilicity

Nanocellulose exhibits superior hydrophilicity compared to carbon nanotubes, enhancing its dispersibility in aqueous environments and suitability for biomedical and environmental applications.

Electrical conductivity

Carbon nanotubes exhibit significantly higher electrical conductivity than nanocellulose, making them more effective for applications requiring superior conductive properties.

Dispersion stability

Nanocellulose exhibits superior dispersion stability in aqueous environments compared to carbon nanotubes due to its hydrophilic surface chemistry and high aspect ratio.

Matrix compatibility

Nanocellulose exhibits superior matrix compatibility compared to carbon nanotubes due to its hydrophilic nature and abundant hydroxyl groups, enabling better dispersion and stronger interfacial bonding in polymer composites.

nanocellulose vs carbon nanotubes Infographic

njnir.com

njnir.com