Refractory ceramics exhibit excellent thermal stability and resistance to chemical degradation at temperatures up to 1800degC, making them suitable for furnace linings and kiln components. Ultra-high temperature ceramics (UHTCs) surpass these limits, maintaining structural integrity above 2000degC, crucial for hypersonic vehicle thermal protection and aerospace applications. The superior melting points and oxidation resistance of UHTCs stem from their dense microstructures and strong covalent bonding, distinguishing them from conventional refractory ceramics.

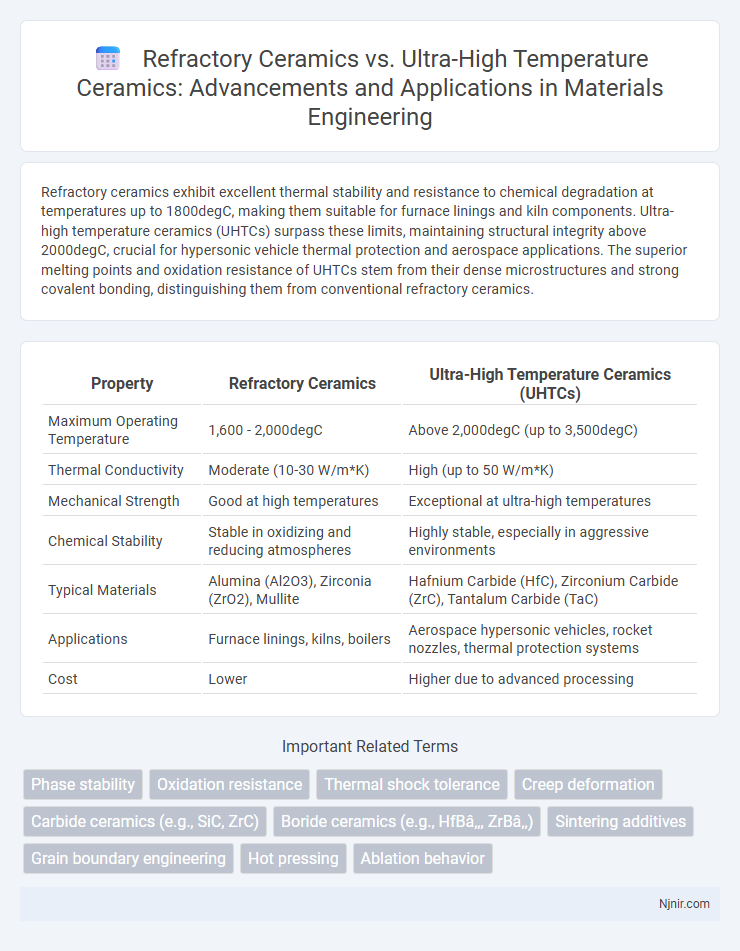

Table of Comparison

| Property | Refractory Ceramics | Ultra-High Temperature Ceramics (UHTCs) |

|---|---|---|

| Maximum Operating Temperature | 1,600 - 2,000degC | Above 2,000degC (up to 3,500degC) |

| Thermal Conductivity | Moderate (10-30 W/m*K) | High (up to 50 W/m*K) |

| Mechanical Strength | Good at high temperatures | Exceptional at ultra-high temperatures |

| Chemical Stability | Stable in oxidizing and reducing atmospheres | Highly stable, especially in aggressive environments |

| Typical Materials | Alumina (Al2O3), Zirconia (ZrO2), Mullite | Hafnium Carbide (HfC), Zirconium Carbide (ZrC), Tantalum Carbide (TaC) |

| Applications | Furnace linings, kilns, boilers | Aerospace hypersonic vehicles, rocket nozzles, thermal protection systems |

| Cost | Lower | Higher due to advanced processing |

Introduction to Refractory and Ultra-High Temperature Ceramics

Refractory ceramics are materials designed to withstand extreme heat, typically above 1,500degC, making them essential in industries like steel manufacturing and kiln linings. Ultra-high temperature ceramics (UHTCs) such as zirconium diboride and hafnium carbide exhibit exceptional thermal stability, maintaining strength at temperatures exceeding 2,000degC. These ceramics differ primarily in thermal performance and oxidation resistance, with UHTCs offering superior durability in ultra-high temperature environments such as aerospace and advanced defense applications.

Defining Refractory Ceramics: Properties and Applications

Refractory ceramics are materials designed to withstand extreme temperatures above 1,500degC while maintaining structural integrity and chemical stability, commonly used in furnaces, kilns, and reactors. These ceramics exhibit high melting points, low thermal conductivity, excellent corrosion resistance, and mechanical strength under thermal stress. Applications span steelmaking, glass production, and chemical processing industries, where durability at elevated temperatures is critical.

Ultra-High Temperature Ceramics: Key Characteristics

Ultra-high temperature ceramics (UHTCs) are distinguished by their exceptional melting points, often exceeding 3000degC, making them ideal for extreme environments such as hypersonic flight and rocket propulsion. Common UHTC materials include zirconium diboride (ZrB2) and hafnium carbide (HfC), known for their high thermal conductivity, hardness, and resistance to oxidation at elevated temperatures. In comparison to traditional refractory ceramics, UHTCs offer superior mechanical strength and thermal stability under intense heat and oxidative conditions, enabling advanced aerospace and defense applications.

Thermal Stability Comparison

Refractory ceramics exhibit excellent thermal stability with melting points typically ranging between 1,500degC and 2,000degC, making them suitable for industrial furnaces and kilns. Ultra-high temperature ceramics (UHTCs), including materials like zirconium diboride (ZrB2) and hafnium carbide (HfC), maintain structural integrity at temperatures exceeding 3,000degC, surpassing conventional refractories in aggression environments such as hypersonic vehicle leading edges and rocket nozzles. The thermal stability of UHTCs is largely attributed to their strong covalent bonding and high melting points, offering superior resistance to oxidation and thermal shock compared to traditional refractory ceramics.

Mechanical Strength and Toughness

Ultra-high temperature ceramics (UHTCs) like zirconium diboride exhibit superior mechanical strength and toughness compared to conventional refractory ceramics such as alumina and silicon carbide, especially at temperatures above 2000degC. UHTCs maintain structural integrity under extreme thermal and mechanical stresses, making them ideal for aerospace and hypersonic applications. Refractory ceramics demonstrate lower fracture toughness and typically experience degradation in mechanical properties at elevated temperatures.

Chemical Resistance and Environmental Performance

Refractory ceramics exhibit excellent chemical resistance, particularly against acids and molten metals, making them suitable for high-temperature industrial processes. Ultra-high temperature ceramics (UHTCs), including materials like zirconium diboride and hafnium carbide, offer superior environmental performance with enhanced oxidation resistance at temperatures exceeding 2000degC. Their robustness in extreme oxidative and corrosive atmospheres ensures longer service life in aerospace and hypersonic applications compared to traditional refractory ceramics.

Manufacturing Processes and Challenges

Refractory ceramics are typically manufactured using traditional sintering and hot pressing techniques, while ultra-high temperature ceramics (UHTCs) require advanced processes like spark plasma sintering and chemical vapor deposition due to their extreme melting points above 3000degC. The primary challenges in refractory ceramics involve controlling porosity and grain growth to enhance thermal shock resistance, whereas UHTCs face difficulties in achieving crack-free dense monoliths and managing rapid oxidation at high temperatures. Manufacturing UHTCs demands precise temperature control and atmosphere management to maintain phase stability and mechanical integrity under extreme thermal environments.

Cost Efficiency and Material Availability

Refractory ceramics generally offer higher cost efficiency due to widespread availability of raw materials and established manufacturing processes, making them suitable for large-scale industrial applications. Ultra-high temperature ceramics (UHTCs) feature superior thermal and mechanical properties but come with significantly higher material and processing costs, limiting their use to specialized fields such as aerospace and defense. Material availability for refractory ceramics is abundant worldwide, whereas UHTC raw materials, like zirconium diboride and hafnium carbide, face supply constraints and higher extraction expenses.

Emerging Trends in High-Temperature Ceramics

Emerging trends in high-temperature ceramics highlight advancements in ultrahigh-temperature ceramics (UHTCs) such as zirconium diboride (ZrB2) and hafnium diboride (HfB2), which exhibit superior melting points above 3000degC compared to traditional refractory ceramics like alumina and silicon carbide. Research is intensifying on enhancing thermal shock resistance and oxidation protection through innovative coatings and composite formulations for UHTCs, enabling their use in aerospace, hypersonic vehicles, and nuclear reactors. Integration of nanostructured reinforcements and additive manufacturing techniques is driving the development of high-performance ceramics with tailored microstructures, boosting mechanical strength and thermal stability beyond conventional refractory materials.

Future Prospects and Industrial Applications

Ultra-high temperature ceramics (UHTCs) offer superior thermal stability and oxidation resistance compared to conventional refractory ceramics, enabling their use in extreme environments such as hypersonic flight and nuclear reactors. Future prospects for UHTCs include advancements in additive manufacturing and nanostructuring to enhance toughness and thermal shock resistance, expanding their industrial applications in aerospace, defense, and energy sectors. Refractory ceramics continue to be vital in traditional high-temperature processes like steelmaking and glass production, but ongoing research aims to improve their lifespan and performance through innovative composite materials.

Phase stability

Ultra-high temperature ceramics exhibit superior phase stability compared to refractory ceramics, maintaining structural integrity at temperatures exceeding 3000degC.

Oxidation resistance

Ultra-high temperature ceramics exhibit superior oxidation resistance compared to traditional refractory ceramics, enabling enhanced durability in extreme high-temperature environments.

Thermal shock tolerance

Ultra-high temperature ceramics exhibit superior thermal shock tolerance compared to refractory ceramics due to their higher melting points and enhanced thermal stability under rapid temperature fluctuations.

Creep deformation

Ultra-high temperature ceramics exhibit significantly lower creep deformation rates than traditional refractory ceramics due to their superior thermal stability and enhanced mechanical strength at temperatures exceeding 2000degC.

Carbide ceramics (e.g., SiC, ZrC)

Carbide ceramics such as silicon carbide (SiC) and zirconium carbide (ZrC) exhibit superior thermal stability and oxidation resistance in ultra-high temperature ceramics compared to traditional refractory ceramics, making them ideal for aerospace and defense applications.

Boride ceramics (e.g., HfB₂, ZrB₂)

Boride ceramics such as HfB2 and ZrB2 exhibit superior oxidation resistance and melting points above 3000degC, making them crucial ultra-high temperature ceramics that outperform traditional refractory ceramics in aerospace and hypersonic applications.

Sintering additives

Sintering additives in refractory ceramics typically include oxides like Al2O3 and MgO to enhance densification, whereas ultra-high temperature ceramics use carbides and borides such as ZrB2 and HfC additives to improve sintering at temperatures above 2000degC.

Grain boundary engineering

Grain boundary engineering in ultra-high temperature ceramics enhances thermal stability and mechanical strength beyond conventional refractory ceramics by optimizing grain size, boundary phases, and impurity segregation.

Hot pressing

Hot pressing enhances densification and mechanical strength in refractory ceramics but requires higher temperatures and pressures to effectively sinter ultra-high temperature ceramics due to their superior thermal stability.

Ablation behavior

Ultra-high temperature ceramics exhibit superior ablation resistance compared to refractory ceramics due to their enhanced thermal stability and oxidation resistance at extreme temperatures above 2000degC.

Refractory ceramics vs Ultra-high temperature ceramics Infographic

njnir.com

njnir.com