Ceramic Matrix Composites (CMCs) exhibit superior mechanical strength and thermal stability compared to Glass Matrix Composites (GMCs), making them ideal for high-temperature structural applications. The enhanced fracture toughness and resistance to thermal shock in CMCs result from their ceramic fiber reinforcements, whereas GMCs typically offer better optical transparency and chemical inertness. Optimizing matrix and fiber interactions in CMCs leads to improved durability and performance in aerospace and energy industries, while GMCs are preferred in optical and electronic devices due to their unique glass properties.

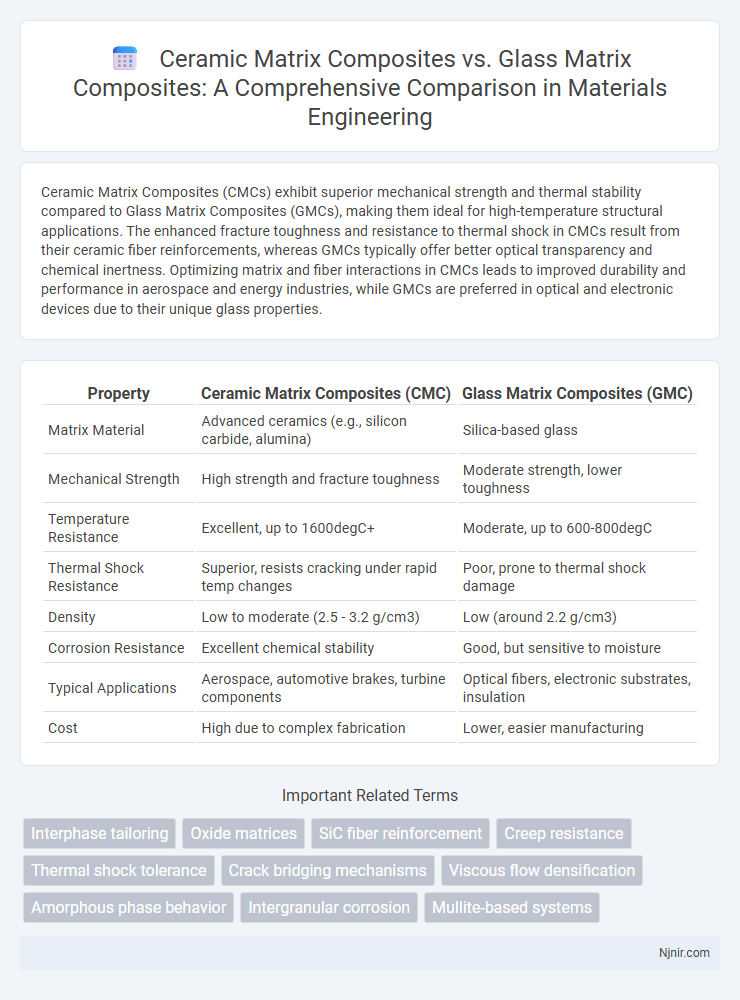

Table of Comparison

| Property | Ceramic Matrix Composites (CMC) | Glass Matrix Composites (GMC) |

|---|---|---|

| Matrix Material | Advanced ceramics (e.g., silicon carbide, alumina) | Silica-based glass |

| Mechanical Strength | High strength and fracture toughness | Moderate strength, lower toughness |

| Temperature Resistance | Excellent, up to 1600degC+ | Moderate, up to 600-800degC |

| Thermal Shock Resistance | Superior, resists cracking under rapid temp changes | Poor, prone to thermal shock damage |

| Density | Low to moderate (2.5 - 3.2 g/cm3) | Low (around 2.2 g/cm3) |

| Corrosion Resistance | Excellent chemical stability | Good, but sensitive to moisture |

| Typical Applications | Aerospace, automotive brakes, turbine components | Optical fibers, electronic substrates, insulation |

| Cost | High due to complex fabrication | Lower, easier manufacturing |

Introduction to Matrix Composites

Matrix composites consist of a continuous phase (matrix) embedded with reinforcement materials to enhance mechanical properties. Ceramic Matrix Composites (CMCs) utilize ceramic materials such as silicon carbide or alumina as the matrix, offering superior high-temperature resistance and fracture toughness compared to traditional ceramics. Glass Matrix Composites (GMCs) employ glass-based matrices, providing advantages in optical clarity and chemical resistance, but generally exhibit lower mechanical strength and thermal stability relative to CMCs.

Fundamental Structure of Ceramic Matrix Composites

Ceramic Matrix Composites (CMCs) consist of ceramic fibers embedded within a ceramic matrix, enhancing toughness and thermal stability compared to monolithic ceramics. The fundamental structure of CMCs features a continuous ceramic phase reinforced by fibers such as silicon carbide or alumina, which improves damage tolerance and resistance to crack propagation. In contrast, Glass Matrix Composites use a glassy matrix with embedded fibers, offering lower thermal resistance and mechanical strength relative to CMCs.

Fundamental Structure of Glass Matrix Composites

Glass Matrix Composites consist of a glass-based amorphous matrix embedded with reinforcing fibers or particles, enhancing mechanical properties such as strength and toughness. The fundamental structure features a vitreous glass phase that provides excellent thermal resistance and chemical durability while the dispersed fibers, often made from materials like silica or alumina, improve fracture toughness and stiffness. This combination enables Glass Matrix Composites to maintain structural integrity under high-temperature and corrosive environments, distinguishing them from Ceramic Matrix Composites that usually have crystalline ceramic matrices.

Comparative Mechanical Properties

Ceramic Matrix Composites (CMCs) exhibit superior fracture toughness and higher temperature resistance compared to Glass Matrix Composites (GMCs), making them ideal for applications demanding exceptional mechanical strength and thermal stability. GMCs typically offer better impact resistance and lower density than CMCs, which is advantageous in lightweight structural components. The elastic modulus of CMCs generally surpasses that of GMCs, resulting in improved stiffness and load-bearing capacity under mechanical stress.

Thermal Stability and Resistance

Ceramic Matrix Composites exhibit superior thermal stability withstanding temperatures above 1,500degC, making them ideal for high-temperature aerospace and turbine applications. Glass Matrix Composites, while offering good thermal resistance up to around 600-800degC, are more susceptible to thermal shock and degradation over time. The enhanced resistance of Ceramic Matrix Composites to oxidation and thermal fatigue significantly outperforms Glass Matrix Composites in extreme heat environments.

Processing and Manufacturing Techniques

Ceramic Matrix Composites (CMCs) typically utilize processes like chemical vapor infiltration (CVI) and liquid silicon infiltration (LSI) to achieve high-temperature resistance and structural reliability, whereas Glass Matrix Composites (GMCs) often rely on melting and casting or sol-gel techniques for enhanced optical and thermal properties. CMC manufacturing demands precise control over fiber-matrix bonding to prevent crack propagation, while GMC processing emphasizes uniform glass distribution and defect minimization for improved mechanical performance. Advances in additive manufacturing and hot pressing are increasingly applied to both composites to optimize microstructure and reduce production costs.

Applications in Aerospace and Automotive Industries

Ceramic Matrix Composites (CMCs) offer superior high-temperature resistance and mechanical strength, making them ideal for aerospace applications such as turbine engine components and thermal protection systems. Glass Matrix Composites (GMCs) provide excellent corrosion resistance and electrical insulation, which suits automotive applications like battery casings and sensor housings. The aerospace industry benefits from CMCs' lightweight durability under extreme conditions, while the automotive sector leverages GMCs for cost-effective, durable, and lightweight materials in electric vehicle components.

Cost and Economic Considerations

Ceramic Matrix Composites (CMCs) generally exhibit higher production costs than Glass Matrix Composites (GMCs) due to advanced raw materials and complex manufacturing processes. GMCs offer a more economical solution with lower material expenses and simplified fabrication, making them suitable for applications requiring cost-efficiency. The economic feasibility of CMCs improves in high-performance sectors such as aerospace or automotive, where long-term durability offsets initial investment.

Environmental Durability and Aging

Ceramic Matrix Composites (CMCs) exhibit superior environmental durability due to their enhanced resistance to high temperatures, oxidation, and corrosion compared to Glass Matrix Composites (GMCs). Aging in CMCs results in minimal microstructural degradation, allowing them to maintain mechanical integrity over extended periods under harsh environmental conditions. In contrast, GMCs are more prone to hydrolytic attack and glass phase leaching, which accelerate aging and reduce long-term performance in aggressive environments.

Future Trends in Matrix Composites

Future trends in matrix composites highlight the growing emphasis on Ceramic Matrix Composites (CMCs) due to their superior thermal stability, high strength-to-weight ratio, and enhanced oxidation resistance compared to Glass Matrix Composites (GMCs). Advancements in manufacturing techniques such as nano-engineering and additive manufacturing are facilitating the development of CMCs with tailored microstructures for aerospace, automotive, and energy applications. Meanwhile, research continues on improving the toughness and cost-effectiveness of Glass Matrix Composites, positioning them as viable options for low-weight structural components requiring transparency or electromagnetic shielding.

Interphase tailoring

Interphase tailoring in Ceramic Matrix Composites enhances thermal stability and mechanical strength by optimizing fiber-matrix bonding, whereas Glass Matrix Composites require different interphase modifications to improve transparency and fracture resistance.

Oxide matrices

Oxide ceramic matrix composites offer superior high-temperature stability and corrosion resistance compared to glass matrix composites, making them ideal for aerospace and industrial applications requiring enhanced mechanical strength and thermal endurance.

SiC fiber reinforcement

Silicon carbide (SiC) fiber reinforcement in ceramic matrix composites (CMCs) enhances high-temperature strength and oxidation resistance, outperforming glass matrix composites in thermal stability and mechanical durability for aerospace and structural applications.

Creep resistance

Ceramic Matrix Composites exhibit superior creep resistance compared to Glass Matrix Composites due to their higher thermal stability and stronger fiber-matrix bonding.

Thermal shock tolerance

Ceramic Matrix Composites exhibit superior thermal shock tolerance compared to Glass Matrix Composites due to their enhanced crack resistance and higher operating temperature capabilities.

Crack bridging mechanisms

Ceramic Matrix Composites exhibit superior crack bridging mechanisms through fiber pull-out and crack deflection, enhancing fracture toughness compared to Glass Matrix Composites, which primarily rely on weaker interfacial bonding and limited crack bridging.

Viscous flow densification

Ceramic Matrix Composites exhibit superior viscous flow densification compared to Glass Matrix Composites due to their enhanced thermal stability and controlled microstructural development.

Amorphous phase behavior

Ceramic Matrix Composites exhibit enhanced thermal stability and mechanical strength due to controlled crystalline-amorphous phase interfaces, whereas Glass Matrix Composites display superior fracture toughness attributed to the dominant amorphous phase behavior facilitating energy dissipation.

Intergranular corrosion

Ceramic Matrix Composites exhibit superior resistance to intergranular corrosion compared to Glass Matrix Composites due to their enhanced grain boundary stability and reduced susceptibility to chemical attack.

Mullite-based systems

Mullite-based Ceramic Matrix Composites exhibit superior high-temperature stability and thermal shock resistance compared to Glass Matrix Composites, making them ideal for advanced aerospace and energy applications.

Ceramic Matrix Composites vs Glass Matrix Composites Infographic

njnir.com

njnir.com