Green composites utilize natural fibers and biodegradable matrices, reducing environmental impact compared to conventional composites made with synthetic fibers and petroleum-based resins. These sustainable materials offer comparable mechanical properties while enhancing recyclability and lowering carbon footprints. Advancements in green composite technology are driving widespread adoption in automotive, construction, and consumer goods industries seeking eco-friendly alternatives.

Table of Comparison

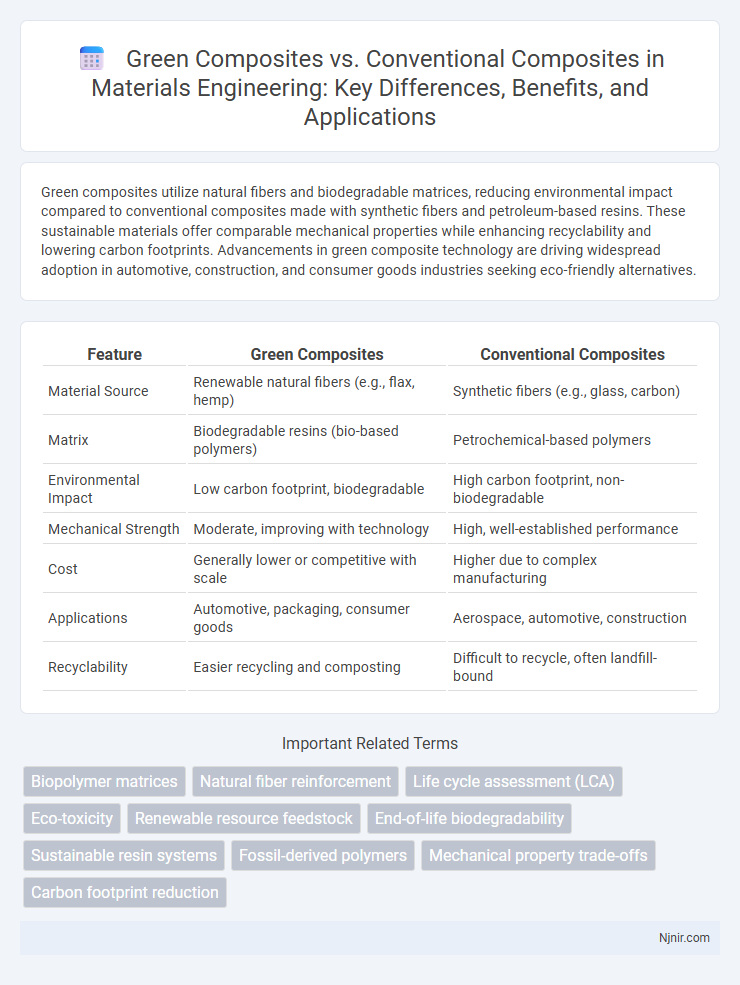

| Feature | Green Composites | Conventional Composites |

|---|---|---|

| Material Source | Renewable natural fibers (e.g., flax, hemp) | Synthetic fibers (e.g., glass, carbon) |

| Matrix | Biodegradable resins (bio-based polymers) | Petrochemical-based polymers |

| Environmental Impact | Low carbon footprint, biodegradable | High carbon footprint, non-biodegradable |

| Mechanical Strength | Moderate, improving with technology | High, well-established performance |

| Cost | Generally lower or competitive with scale | Higher due to complex manufacturing |

| Applications | Automotive, packaging, consumer goods | Aerospace, automotive, construction |

| Recyclability | Easier recycling and composting | Difficult to recycle, often landfill-bound |

Introduction to Composites in Materials Engineering

Green composites incorporate natural fibers such as flax, jute, or hemp combined with bio-based resins, offering enhanced biodegradability and lower environmental impact compared to conventional composites made from synthetic fibers like glass or carbon with petrochemical matrices. These materials provide comparable mechanical properties while reducing reliance on non-renewable resources and improving sustainability in materials engineering. Advances in green composites focus on optimizing fiber-matrix compatibility, durability, and life-cycle performance to meet the demands of structural and automotive applications.

Defining Green Composites and Conventional Composites

Green composites primarily consist of natural fibers such as hemp, flax, or jute combined with biodegradable or bio-based resins, emphasizing sustainability and reduced environmental impact. Conventional composites typically use synthetic fibers like glass or carbon reinforced with petroleum-based polymers known for their high strength-to-weight ratios and durability. The key distinction lies in the material origin, biodegradability, and environmental footprint, with green composites offering a renewable alternative to the predominantly fossil-fuel-derived conventional composites.

Raw Materials: Renewable vs. Non-renewable Sources

Green composites utilize renewable raw materials such as natural fibers from plants, which promote sustainability by reducing dependence on fossil fuels. Conventional composites rely primarily on non-renewable petroleum-based resins and synthetic fibers like glass or carbon fibers, contributing to environmental degradation. The use of bio-based matrices in green composites enhances biodegradability and lowers the carbon footprint compared to traditional composites.

Manufacturing Processes: Sustainability and Efficiency

Green composites utilize renewable bio-based fibers and resins, significantly lowering environmental impact through reduced carbon emissions and energy consumption during manufacturing. Conventional composites often rely on synthetic fibers and petroleum-based resins, which involve energy-intensive processes and produce non-biodegradable waste. Advances in green composite manufacturing, including bio-resin infusion and natural fiber pre-treatment, enhance production efficiency while promoting sustainability by minimizing toxic byproducts and facilitating easier recycling.

Mechanical and Physical Properties Comparison

Green composites exhibit competitive mechanical properties such as tensile strength and stiffness compared to conventional composites, though they often show lower impact resistance due to the use of natural fibers like flax or hemp. Physically, green composites offer advantages in density, being lighter and more sustainable, with superior biodegradability and reduced environmental footprint relative to synthetic fiber-reinforced composites. Moisture absorption tends to be higher in green composites, affecting dimensional stability and long-term durability when exposed to humid conditions.

Environmental Impact and Life Cycle Assessment

Green composites, made from natural fibers and bio-based matrices, exhibit significantly lower environmental impact compared to conventional composites derived from synthetic fibers and petrochemical resins. Life Cycle Assessment (LCA) studies reveal that green composites reduce carbon footprint, energy consumption, and waste generation throughout production, use, and disposal phases. These eco-friendly materials contribute to sustainable manufacturing by enhancing biodegradability and facilitating easier recycling options, thereby minimizing long-term environmental burdens.

Applications in Industry: Present and Future Trends

Green composites, composed of natural fibers and biodegradable resins, are increasingly utilized in automotive, aerospace, and construction industries due to their lightweight, sustainable properties, and reduced environmental impact. Conventional composites, often made from synthetic fibers like carbon or glass and non-biodegradable polymers, dominate high-performance applications but face challenges related to recyclability and ecological footprint. Future trends emphasize hybrid composites combining green and conventional materials, aiming to balance performance with sustainability while expanding applications in packaging, consumer electronics, and renewable energy sectors.

Cost Analysis and Economic Feasibility

Green composites generally exhibit higher initial material costs compared to conventional composites due to bio-based fiber and resin sourcing. However, economic feasibility improves through reduced disposal fees, lower environmental taxes, and potential government incentives promoting sustainability. Lifecycle cost analysis often reveals green composites as a cost-effective solution when factoring durability, recyclability, and reduced carbon footprint in long-term applications.

Challenges and Limitations of Green Composites

Green composites face significant challenges including lower mechanical strength and durability compared to conventional composites, which limits their use in high-performance applications. Issues with moisture absorption and thermal stability often lead to reduced lifespan and dimensional instability. Furthermore, variability in natural fiber properties and the lack of standardized processing techniques hinder large-scale manufacturing and consistent quality control.

Future Directions and Innovations in Composite Materials

Green composites, derived from renewable resources such as natural fibers and bio-based polymers, offer promising advancements in sustainability and biodegradability compared to conventional composites dominated by synthetic fibers and petroleum-based resins. Future directions emphasize enhancing mechanical properties and environmental performance through novel hybridization techniques, bio-resin development, and advanced manufacturing processes like additive manufacturing and nanotechnology integration. Innovations also target recyclability improvements and lifecycle assessments, positioning green composites as viable, eco-friendly alternatives meeting stringent regulatory and market demands in automotive, aerospace, and construction industries.

Biopolymer matrices

Green composites with biopolymer matrices offer enhanced biodegradability and reduced environmental impact compared to conventional composites typically based on petroleum-derived polymers.

Natural fiber reinforcement

Natural fiber reinforcement in green composites offers sustainable, lightweight, and biodegradable alternatives to conventional composites typically reinforced with synthetic fibers like glass or carbon.

Life cycle assessment (LCA)

Life cycle assessment (LCA) reveals that green composites deliver significantly lower environmental impacts across raw material extraction, manufacturing, use, and end-of-life stages compared to conventional composites made from petroleum-based fibers and resins.

Eco-toxicity

Green composites exhibit significantly lower eco-toxicity compared to conventional composites due to their biodegradable natural fibers and non-toxic bio-resins.

Renewable resource feedstock

Green composites use renewable resource feedstocks such as plant fibers and biopolymers, offering a sustainable alternative to conventional composites made from non-renewable petroleum-based materials.

End-of-life biodegradability

Green composites offer superior end-of-life biodegradability compared to conventional composites, significantly reducing environmental impact through natural decomposition.

Sustainable resin systems

Sustainable resin systems in green composites, derived from renewable resources and exhibiting lower environmental impact, offer enhanced biodegradability and reduced carbon footprint compared to conventional petroleum-based resin systems.

Fossil-derived polymers

Green composites utilize bio-based polymers that reduce reliance on fossil-derived polymers commonly found in conventional composites, enhancing sustainability and lowering environmental impact.

Mechanical property trade-offs

Green composites often exhibit lower tensile strength and stiffness compared to conventional composites but offer improved biodegradability and environmental sustainability.

Carbon footprint reduction

Green composites reduce carbon footprint by up to 60% compared to conventional composites through the use of bio-based fibers and resins derived from renewable resources.

green composites vs conventional composites Infographic

njnir.com

njnir.com