Functionally graded materials (FGMs) exhibit gradual variations in composition and microstructure, enhancing properties such as thermal resistance and mechanical strength compared to homogeneous materials, which have uniform properties throughout. FGMs reduce stress concentration and improve bonding between different material layers, making them ideal for applications involving thermal gradients and mechanical loads. Homogeneous materials may fail under extreme conditions due to uniform stress distribution, whereas FGMs optimize performance through spatially tailored properties.

Table of Comparison

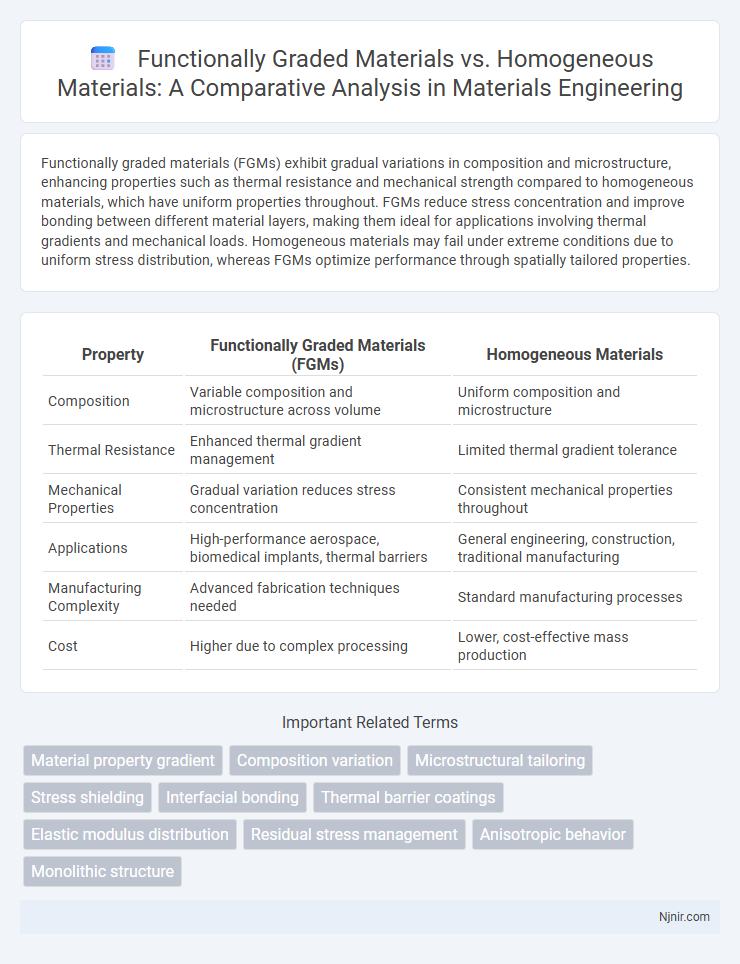

| Property | Functionally Graded Materials (FGMs) | Homogeneous Materials |

|---|---|---|

| Composition | Variable composition and microstructure across volume | Uniform composition and microstructure |

| Thermal Resistance | Enhanced thermal gradient management | Limited thermal gradient tolerance |

| Mechanical Properties | Gradual variation reduces stress concentration | Consistent mechanical properties throughout |

| Applications | High-performance aerospace, biomedical implants, thermal barriers | General engineering, construction, traditional manufacturing |

| Manufacturing Complexity | Advanced fabrication techniques needed | Standard manufacturing processes |

| Cost | Higher due to complex processing | Lower, cost-effective mass production |

Introduction to Materials Engineering

Functionally graded materials (FGMs) exhibit continuous variations in composition and structure tailored to specific performance requirements, enhancing properties like thermal resistance, strength, and corrosion resistance compared to homogeneous materials with uniform composition. FGMs optimize material behavior by minimizing stress concentrations and improving durability in applications such as aerospace, biomedical implants, and thermal barriers. Understanding these gradients is crucial in materials engineering for designing advanced components that balance mechanical and thermal demands effectively.

Defining Functionally Graded Materials (FGMs)

Functionally graded materials (FGMs) are advanced composites characterized by gradual variations in composition and structure over volume, resulting in corresponding changes in their mechanical, thermal, or chemical properties. Unlike homogeneous materials, which possess uniform properties throughout, FGMs are engineered to optimize performance under specific operating conditions by minimizing stress concentrations and enhancing durability. This spatial grading enhances their applications in aerospace, biomedical implants, and thermal barrier coatings where tailored property distribution is crucial.

Characteristics of Homogeneous Materials

Homogeneous materials exhibit uniform composition and consistent properties throughout their entire volume, resulting in predictable mechanical and thermal behavior under various conditions. Their isotropic nature ensures that properties such as strength, conductivity, and stiffness remain constant regardless of the direction of applied forces or environmental factors. This uniformity simplifies manufacturing processes and performance analysis, but limits adaptability compared to functionally graded materials which have spatially varying properties tailored for specific applications.

Microstructural Differences: FGMs vs Homogeneous Materials

Functionally graded materials (FGMs) exhibit gradual variation in composition and microstructure across their volume, resulting in spatially tailored properties that enhance performance under thermal and mechanical gradients. Homogeneous materials possess uniform microstructure and composition throughout, leading to consistent but less adaptable behavior under variable conditions. The microstructural gradient in FGMs enables improved stress distribution and resistance to thermal mismatch compared to the uniform grain size and phase distribution in homogeneous materials.

Mechanical Properties Comparison

Functionally graded materials (FGMs) exhibit superior mechanical properties compared to homogeneous materials, with enhanced strength and toughness due to their gradual variation in composition and microstructure. The continuous transition in FGMs reduces stress concentrations and improves resistance to thermal and mechanical fatigue. Homogeneous materials often suffer from abrupt property changes, leading to higher susceptibility to cracking and failure under complex loading conditions.

Thermal and Chemical Performance

Functionally graded materials (FGMs) exhibit enhanced thermal resistance and chemical stability due to their gradual variation in composition, which reduces thermal stress and improves corrosion resistance compared to homogeneous materials. Homogeneous materials have uniform properties, often leading to higher susceptibility to thermal cracking and chemical degradation under extreme conditions. The graded structure of FGMs enables tailored thermal conductivity and chemical durability, making them ideal for high-performance applications in aerospace, automotive, and chemical industries.

Manufacturing Techniques of FGMs and Homogeneous Materials

Functionally graded materials (FGMs) require advanced manufacturing techniques such as additive manufacturing, powder metallurgy, and centrifugal casting to achieve gradual variations in composition and properties. Homogeneous materials are typically produced using conventional methods like forging, extrusion, rolling, and casting that yield uniform material properties throughout. The complexity of FGM fabrication involves precise control of material gradients, whereas homogeneous material manufacturing prioritizes consistency and repeatability.

Application Areas in Modern Engineering

Functionally graded materials (FGMs) exhibit spatial variations in composition and structure, making them ideal for aerospace, biomedical implants, and thermal barrier coatings where tailored mechanical and thermal properties are critical. Homogeneous materials, with uniform composition and predictable behavior, commonly serve in structural components, automotive parts, and general manufacturing due to their ease of fabrication and cost-effectiveness. FGMs outperform homogeneous materials in environments requiring gradual stress distribution and multi-functional performance, enhancing durability and efficiency in advanced engineering applications.

Advantages and Limitations

Functionally graded materials (FGMs) offer superior thermal resistance and tailored mechanical properties by gradually varying composition, reducing stress concentrations and improving structural integrity compared to homogeneous materials. Homogeneous materials provide uniform properties and simpler manufacturing processes but often face limitations in performance under thermal or mechanical gradients. FGMs present challenges in complex fabrication techniques and higher production costs, which can restrict widespread application despite their enhanced functionality.

Future Trends in Material Design and Development

Functionally graded materials (FGMs) exhibit spatial variation in composition and structure, enabling customized mechanical, thermal, and chemical properties that outperform homogeneous materials in complex applications. Emerging trends in material design emphasize multi-scale modeling, additive manufacturing, and AI-driven optimization to tailor FGMs for aerospace, biomedical implants, and energy systems. Advances in nano-engineering and smart material integration further expand the potential of FGMs, driving a shift from traditional homogeneous materials toward multifunctional, adaptive solutions.

Material property gradient

Functionally graded materials exhibit a continuous variation in material properties across their volume, enhancing performance and stress distribution compared to the uniform properties of homogeneous materials.

Composition variation

Functionally graded materials feature a gradual composition variation that enhances performance by reducing stress concentrations, unlike homogeneous materials which have a uniform composition throughout.

Microstructural tailoring

Functionally graded materials exhibit spatially varying microstructural tailoring that enables gradual transitions in composition and properties, unlike homogeneous materials with uniform microstructures, optimizing performance for specific engineering applications.

Stress shielding

Functionally graded materials reduce stress shielding more effectively than homogeneous materials by gradually varying their mechanical properties to better match the surrounding tissue stiffness.

Interfacial bonding

Functionally graded materials exhibit superior interfacial bonding due to gradual compositional transitions that minimize stress concentrations compared to the abrupt interfaces in homogeneous materials.

Thermal barrier coatings

Functionally graded materials offer superior thermal barrier coating performance by gradually varying composition and microstructure, enhancing thermal resistance and reducing thermal stress compared to homogeneous materials.

Elastic modulus distribution

Functionally graded materials exhibit a continuous variation in elastic modulus across their volume, providing tailored mechanical properties, while homogeneous materials maintain a uniform elastic modulus throughout their structure.

Residual stress management

Functionally graded materials exhibit superior residual stress management compared to homogeneous materials due to their gradual variation in composition and microstructure, which reduces stress concentration and enhances structural integrity.

Anisotropic behavior

Functionally graded materials exhibit spatially varying anisotropic behavior tailored to specific performance requirements, whereas homogeneous materials demonstrate uniform anisotropy throughout their structure.

Monolithic structure

Functionally graded materials in monolithic structures offer enhanced thermal resistance and mechanical properties by gradually varying composition, unlike homogeneous materials with uniform properties throughout.

Functionally graded materials vs Homogeneous materials Infographic

njnir.com

njnir.com