Self-healing polymers exhibit the ability to autonomously repair damage, enhancing longevity and durability in various materials engineering applications. Conductive polymers, on the other hand, provide electrical conductivity while maintaining the mechanical properties of traditional polymers, making them crucial for flexible electronics and sensors. Comparing both, self-healing polymers prioritize material resilience and extended lifecycle, whereas conductive polymers focus on integrating electrical functionality into polymer matrices.

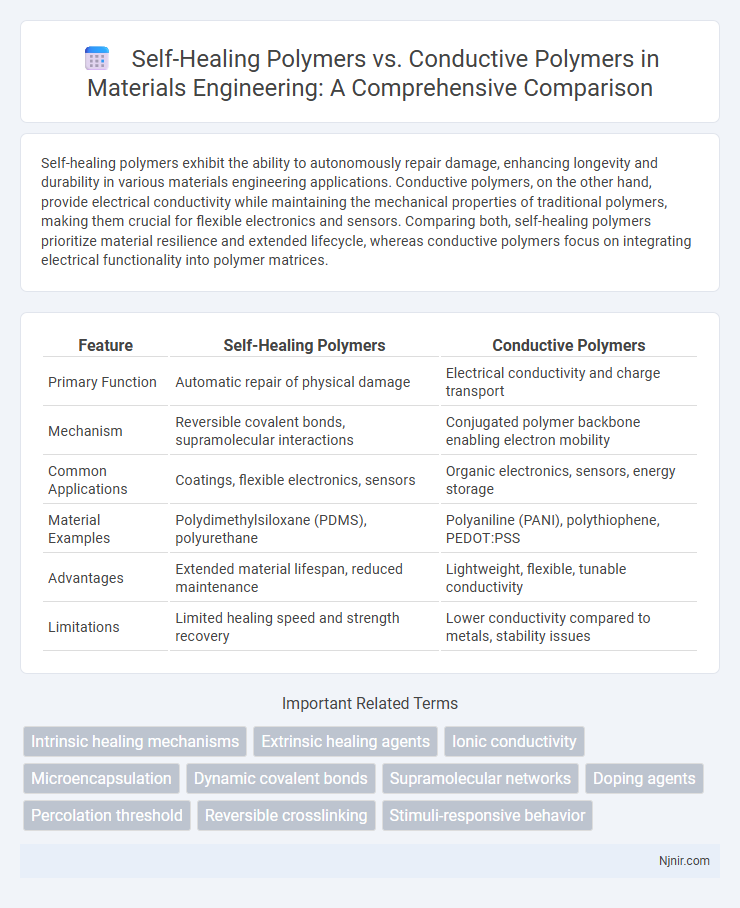

Table of Comparison

| Feature | Self-Healing Polymers | Conductive Polymers |

|---|---|---|

| Primary Function | Automatic repair of physical damage | Electrical conductivity and charge transport |

| Mechanism | Reversible covalent bonds, supramolecular interactions | Conjugated polymer backbone enabling electron mobility |

| Common Applications | Coatings, flexible electronics, sensors | Organic electronics, sensors, energy storage |

| Material Examples | Polydimethylsiloxane (PDMS), polyurethane | Polyaniline (PANI), polythiophene, PEDOT:PSS |

| Advantages | Extended material lifespan, reduced maintenance | Lightweight, flexible, tunable conductivity |

| Limitations | Limited healing speed and strength recovery | Lower conductivity compared to metals, stability issues |

Introduction to Self-Healing and Conductive Polymers

Self-healing polymers possess intrinsic or extrinsic mechanisms that enable them to autonomously repair damage, enhancing durability and longevity in various applications such as coatings, electronics, and biomedical devices. Conductive polymers, characterized by their conjugated molecular structure, facilitate electron transport and find widespread use in flexible electronics, sensors, and energy storage systems. Comparing these materials highlights the multifunctionality of self-healing polymers in mechanical resilience versus the electrical conductivity emphasis of conductive polymers, driving innovation in smart material design.

Fundamental Mechanisms: Self-Healing vs Conductivity

Self-healing polymers restore mechanical integrity through intrinsic or extrinsic mechanisms such as reversible covalent bonds, hydrogen bonding, or microencapsulated healing agents that trigger repair upon damage. Conductive polymers achieve electrical conductivity via conjugated p-electron systems enabling charge transport along polymer backbones, often enhanced by doping with electron donors or acceptors. The fundamental difference lies in self-healing polymers prioritizing dynamic bond reformation for material restoration, whereas conductive polymers optimize electron delocalization for efficient charge mobility.

Chemical Structures and Material Composition

Self-healing polymers typically incorporate dynamic covalent bonds or supramolecular interactions such as hydrogen bonding or metal-ligand coordination within their chemical structures to enable autonomous repair and maintain mechanical integrity. Conductive polymers, including polyaniline, polypyrrole, and PEDOT:PSS, feature conjugated backbone structures with alternating single and double bonds facilitating electron delocalization and electrical conductivity. Material composition in self-healing polymers often integrates elastomers or hydrogels combined with dynamic crosslinkers, whereas conductive polymers rely on dopants and molecular design to optimize charge transport and stability.

Key Applications in Modern Engineering

Self-healing polymers are primarily utilized in aerospace and automotive industries for structural components that require extended durability and damage tolerance, enabling materials to autonomously repair cracks and scratches. Conductive polymers find critical applications in flexible electronics, wearable sensors, and energy storage devices due to their ability to conduct electricity while maintaining mechanical flexibility. The integration of self-healing properties with conductivity is driving innovation in smart materials for next-generation electronic devices and soft robotics.

Performance Metrics: Mechanical vs Electrical Properties

Self-healing polymers exhibit exceptional mechanical properties such as high tensile strength and elasticity, enabling them to restore structural integrity after damage, whereas conductive polymers prioritize electrical conductivity, with parameters like charge carrier mobility and conductivity levels being critical performance metrics. The mechanical resilience of self-healing polymers often results in moderate electrical conductivity, limiting their use in electronic applications, while conductive polymers typically show lower mechanical strength and flexibility but superior electrical performance tailored for sensors and flexible electronics. Balancing mechanical durability and electrical efficiency remains a key challenge, driving research towards hybrid materials that integrate self-healing capabilities with enhanced conductivity for multifunctional applications.

Synthesis Methods and Fabrication Techniques

Self-healing polymers are commonly synthesized using dynamic covalent bonds, supramolecular chemistry, and reversible cross-linking, enabling autonomous repair mechanisms during fabrication via molding or 3D printing. Conductive polymers like polyaniline and polythiophene are typically produced through chemical or electrochemical polymerization, with fabrication techniques including spin coating, inkjet printing, and vapor phase polymerization to achieve high electrical conductivity. Advanced fabrication of composite materials combining self-healing and conductive properties often involves layer-by-layer assembly, electrospinning, and in-situ polymerization to optimize mechanical resilience and electrical performance.

Environmental Impact and Sustainability Considerations

Self-healing polymers reduce environmental waste by extending the lifespan of materials, thereby minimizing the need for frequent replacements and lowering resource consumption. Conductive polymers, while essential for electronic applications, often rely on toxic metals and complex synthesis processes that pose challenges for eco-friendly disposal and recycling. Sustainable development favors self-healing polymers for their ability to enhance durability and reduce environmental degradation, whereas conductive polymers require innovation toward greener production methods.

Challenges in Integration and Scalability

Self-healing polymers face significant challenges in integration and scalability due to the complexity of incorporating dynamic covalent bonds or microcapsules that enable repair functions without compromising mechanical strength. Conductive polymers struggle with scalability as their synthesis often requires precise control over doping levels and polymer morphology to maintain consistent electrical conductivity across large areas. Both polymer types demand advanced manufacturing techniques to balance functional performance with cost-effective production for industrial applications.

Recent Advances and Emerging Research Trends

Recent advances in self-healing polymers emphasize dynamic covalent bonds and supramolecular interactions to enhance repair efficiency and material longevity. Conductive polymers research trends focus on doping strategies and molecular engineering to improve electrical conductivity and mechanical flexibility. Emerging studies are integrating self-healing capabilities with conductivity for multifunctional applications in flexible electronics and wearable sensors.

Future Prospects: Towards Multifunctional Polymer Materials

Self-healing polymers exhibit autonomous repair capabilities, enhancing material longevity and reliability, while conductive polymers enable electrical conductivity, crucial for advanced electronics. Future prospects involve integrating self-healing properties with conductivity to develop multifunctional polymer materials suitable for flexible electronics, wearable devices, and smart sensors. Innovations in molecular design and nanocomposites aim to optimize performance, durability, and responsiveness, paving the way for next-generation smart materials.

Intrinsic healing mechanisms

Intrinsic self-healing polymers autonomously repair damage through reversible chemical bonds or dynamic covalent interactions, whereas conductive polymers integrate intrinsic healing via redox-active moieties or p-conjugated systems enabling both electrical conductivity and self-repair.

Extrinsic healing agents

Extrinsic self-healing polymers incorporate microcapsules or vascular networks containing healing agents that release upon damage, whereas conductive polymers typically lack such embedded healing systems and rely more on intrinsic mechanisms for repair.

Ionic conductivity

Self-healing polymers exhibit enhanced ionic conductivity through dynamic reversible bonds enabling efficient ion transport, whereas conductive polymers rely primarily on conjugated backbones for electronic conduction with comparatively limited ionic conductivity.

Microencapsulation

Microencapsulation enhances self-healing polymers by enabling targeted release of healing agents, whereas conductive polymers utilize microencapsulation primarily to protect and control their electrical properties.

Dynamic covalent bonds

Dynamic covalent bonds in self-healing polymers enable reversible bond breakage and reformation for autonomous repair, whereas in conductive polymers, these bonds enhance electrical conductivity stability alongside material flexibility.

Supramolecular networks

Supramolecular networks in self-healing polymers enable reversible non-covalent interactions for autonomous repair, while in conductive polymers, they facilitate dynamic electron pathways enhancing electrical conductivity and material resilience.

Doping agents

Doping agents in conductive polymers enhance electrical conductivity by introducing charge carriers, while in self-healing polymers, they often improve mechanical properties and facilitate healing efficiency through ionic interactions or reversible bonding.

Percolation threshold

Self-healing polymers typically exhibit higher percolation thresholds compared to conductive polymers due to their intrinsic ability to restore network connectivity after damage, impacting electrical conductivity restoration efficiency.

Reversible crosslinking

Reversible crosslinking in self-healing polymers enables autonomous repair of mechanical damage, contrasting with conductive polymers where crosslinking primarily enhances electrical conductivity and stability.

Stimuli-responsive behavior

Self-healing polymers autonomously repair damage through stimuli-responsive mechanisms like temperature or pH changes, while conductive polymers exhibit stimuli-responsive behavior primarily through electrical conductivity modulation in response to environmental factors.

self-healing polymers vs conductive polymers Infographic

njnir.com

njnir.com