Metal Matrix Composites offer superior mechanical strength, thermal conductivity, and wear resistance compared to Polymer Matrix Composites, making them ideal for high-performance applications like aerospace and automotive components. Polymer Matrix Composites provide better corrosion resistance, lower density, and easier manufacturability, favoring lightweight structures and cost-effective production. Selecting between these composites depends on the specific performance requirements, environmental conditions, and budget constraints of the engineering application.

Table of Comparison

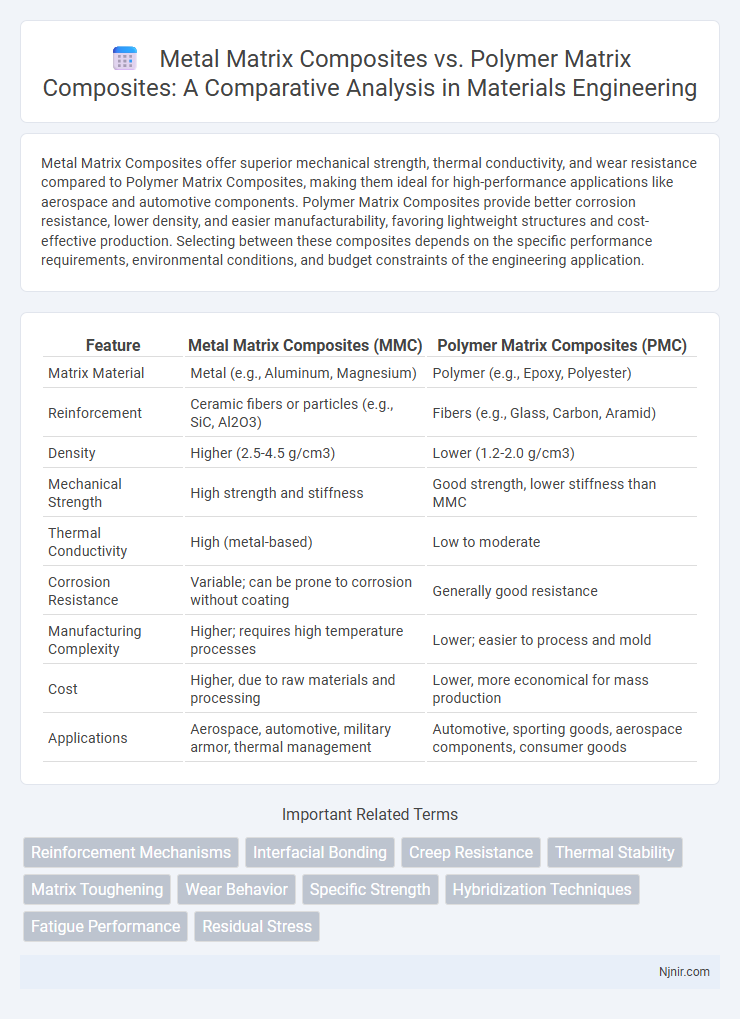

| Feature | Metal Matrix Composites (MMC) | Polymer Matrix Composites (PMC) |

|---|---|---|

| Matrix Material | Metal (e.g., Aluminum, Magnesium) | Polymer (e.g., Epoxy, Polyester) |

| Reinforcement | Ceramic fibers or particles (e.g., SiC, Al2O3) | Fibers (e.g., Glass, Carbon, Aramid) |

| Density | Higher (2.5-4.5 g/cm3) | Lower (1.2-2.0 g/cm3) |

| Mechanical Strength | High strength and stiffness | Good strength, lower stiffness than MMC |

| Thermal Conductivity | High (metal-based) | Low to moderate |

| Corrosion Resistance | Variable; can be prone to corrosion without coating | Generally good resistance |

| Manufacturing Complexity | Higher; requires high temperature processes | Lower; easier to process and mold |

| Cost | Higher, due to raw materials and processing | Lower, more economical for mass production |

| Applications | Aerospace, automotive, military armor, thermal management | Automotive, sporting goods, aerospace components, consumer goods |

Introduction to Metal and Polymer Matrix Composites

Metal Matrix Composites (MMCs) consist of a metal base reinforced with ceramic or metallic fibers, offering superior strength, thermal conductivity, and wear resistance compared to traditional metals. Polymer Matrix Composites (PMCs) use a polymer resin as the matrix combined with reinforcements like glass or carbon fibers, delivering lightweight properties, corrosion resistance, and ease of fabrication. Both MMCs and PMCs serve critical roles in aerospace, automotive, and industrial applications, chosen based on mechanical demands and environmental conditions.

Fundamental Differences in Matrix Materials

Metal Matrix Composites (MMCs) utilize metals such as aluminum, titanium, or magnesium as the matrix, providing high strength, thermal conductivity, and resistance to wear and high temperatures. Polymer Matrix Composites (PMCs) employ thermosetting or thermoplastic polymers like epoxy or polyester, offering lightweight characteristics, corrosion resistance, and ease of fabrication. The fundamental difference lies in the matrix phase: metals impart superior mechanical and thermal performance, while polymers allow for cost-effective, flexible, and lightweight composite structures.

Key Reinforcement Types for MMCs and PMCs

Metal Matrix Composites (MMCs) primarily utilize ceramic reinforcements such as silicon carbide (SiC), aluminum oxide (Al2O3), and boron carbide (B4C) to enhance mechanical properties like strength, wear resistance, and thermal stability. Polymer Matrix Composites (PMCs) commonly incorporate reinforcements like glass fibers, carbon fibers, and aramid fibers to improve stiffness, tensile strength, and impact resistance. The choice of reinforcement in MMCs and PMCs directly influences their performance characteristics and suitability for aerospace, automotive, and industrial applications.

Fabrication Techniques for MMCs vs PMCs

Metal Matrix Composites (MMCs) fabrication techniques primarily include powder metallurgy, infiltration, and casting methods, which enable the integration of reinforcement materials such as ceramics into a metal matrix to enhance mechanical properties and thermal stability. Polymer Matrix Composites (PMCs) are typically fabricated using techniques like hand lay-up, resin transfer molding (RTM), and filament winding, which facilitate the embedding of fibers like carbon or glass into a polymer resin for lightweight and corrosion-resistant applications. MMC fabrication demands higher temperatures and specialized equipment compared to PMC processes, reflecting the intrinsic differences in material handling and performance requirements.

Mechanical Properties Comparison

Metal Matrix Composites (MMCs) exhibit superior mechanical properties such as higher strength, stiffness, and thermal conductivity compared to Polymer Matrix Composites (PMCs), making them ideal for high-stress applications. MMCs maintain better dimensional stability and resistance to wear, creep, and fatigue at elevated temperatures, which exceeds the performance limits of PMCs. PMCs offer advantages in lightweight applications with good impact resistance and corrosion resistance, but their mechanical strength and modulus are generally lower than those of MMCs.

Thermal Stability and Performance

Metal Matrix Composites (MMCs) offer superior thermal stability and performance compared to Polymer Matrix Composites (PMCs), with operating temperatures often exceeding 500degC due to their metallic matrices. MMCs maintain mechanical integrity and resist thermal degradation under high-temperature environments, making them ideal for aerospace and automotive applications. Polymer Matrix Composites typically have lower thermal stability, with maximum service temperatures below 250degC, limiting their use in high-heat scenarios.

Weight and Density Considerations

Metal Matrix Composites (MMCs) typically exhibit higher density than Polymer Matrix Composites (PMCs) due to their metal reinforcements, resulting in increased weight despite superior mechanical strength and thermal conductivity. PMCs offer significant weight advantages with densities often below 2 g/cm3, making them ideal for aerospace and automotive applications where lightweight materials enhance fuel efficiency and performance. The choice between MMCs and PMCs often hinges on balancing weight reduction goals against structural and thermal demands in engineering design.

Cost Analysis and Scalability

Metal Matrix Composites (MMCs) generally exhibit higher initial manufacturing costs due to expensive raw materials and complex processing techniques like powder metallurgy and casting. Polymer Matrix Composites (PMCs) offer lower production costs and greater scalability, benefiting from easier fabrication methods such as molding and curing, which enables mass production with reduced cycle times. The cost-effectiveness of PMCs makes them preferable for large-volume applications, while MMCs are justified in high-performance sectors where enhanced mechanical properties justify the premium.

Typical Applications in Industry Sectors

Metal Matrix Composites (MMCs) are predominantly used in aerospace, automotive, and defense sectors due to their high strength-to-weight ratio, thermal conductivity, and wear resistance, making them ideal for engine components, brake systems, and structural parts. Polymer Matrix Composites (PMCs) find extensive applications in the aerospace, sports equipment, and marine industries because of their lightweight nature, corrosion resistance, and ease of fabrication, often utilized in aircraft interiors, bicycle frames, and boat hulls. Both MMCs and PMCs serve critical roles in enhancing performance and durability across diverse industrial applications.

Future Trends and Innovations

Metal Matrix Composites (MMCs) are evolving with advancements in nano-reinforcements and additive manufacturing techniques, enhancing their strength-to-weight ratio and thermal stability for aerospace and automotive applications. Polymer Matrix Composites (PMCs) are experiencing innovations in bio-based resins and self-healing materials, improving sustainability and durability in construction and consumer electronics. Future trends indicate a convergence of hybrid composites combining MMCs and PMCs to optimize mechanical performance and cost-efficiency in multi-functional materials.

Reinforcement Mechanisms

Metal Matrix Composites utilize rigid ceramic or metallic reinforcements to enhance strength and thermal stability through load transfer and crack deflection, while Polymer Matrix Composites rely on fibrous reinforcements such as carbon or glass fibers to improve mechanical properties via stress distribution and fiber-matrix interfacial bonding.

Interfacial Bonding

Metal Matrix Composites exhibit stronger interfacial bonding due to metallic bonding and higher thermal conductivity, whereas Polymer Matrix Composites rely on chemical adhesion and mechanical interlocking, often resulting in weaker interfaces.

Creep Resistance

Metal Matrix Composites exhibit superior creep resistance compared to Polymer Matrix Composites due to their higher melting points and stronger atomic bonding.

Thermal Stability

Metal Matrix Composites exhibit superior thermal stability compared to Polymer Matrix Composites, making them ideal for high-temperature applications.

Matrix Toughening

Metal Matrix Composites exhibit superior matrix toughening compared to Polymer Matrix Composites due to their enhanced load-bearing capacity and resistance to crack propagation under high-temperature and mechanical stress conditions.

Wear Behavior

Metal matrix composites exhibit superior wear resistance compared to polymer matrix composites due to their higher hardness, thermal stability, and load-bearing capacity.

Specific Strength

Metal matrix composites exhibit higher specific strength than polymer matrix composites due to their superior stiffness and density ratio.

Hybridization Techniques

Hybridization techniques in metal matrix composites enhance mechanical strength and thermal conductivity by integrating diverse reinforcements, whereas polymer matrix composites utilize hybridization to improve flexibility, impact resistance, and weight reduction.

Fatigue Performance

Metal matrix composites offer superior fatigue performance compared to polymer matrix composites due to their higher stiffness, temperature resistance, and crack propagation resistance.

Residual Stress

Metal Matrix Composites exhibit higher residual stress due to thermal expansion mismatch compared to Polymer Matrix Composites, impacting their structural integrity and fatigue resistance.

Metal Matrix Composites vs Polymer Matrix Composites Infographic

njnir.com

njnir.com